Method for producing ferrovanadium nitride by adopting self-propagating high temperature synthesis process

A self-propagating high-temperature, ferrovanadium nitride technology is applied in the field of self-propagating high-temperature synthesis of ferronitride alloys, which can solve the problem of insufficient output, and achieve the effects of fast synthesis speed, stable comprehensive performance of steel, and reduced fluctuation value of mechanical properties of steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

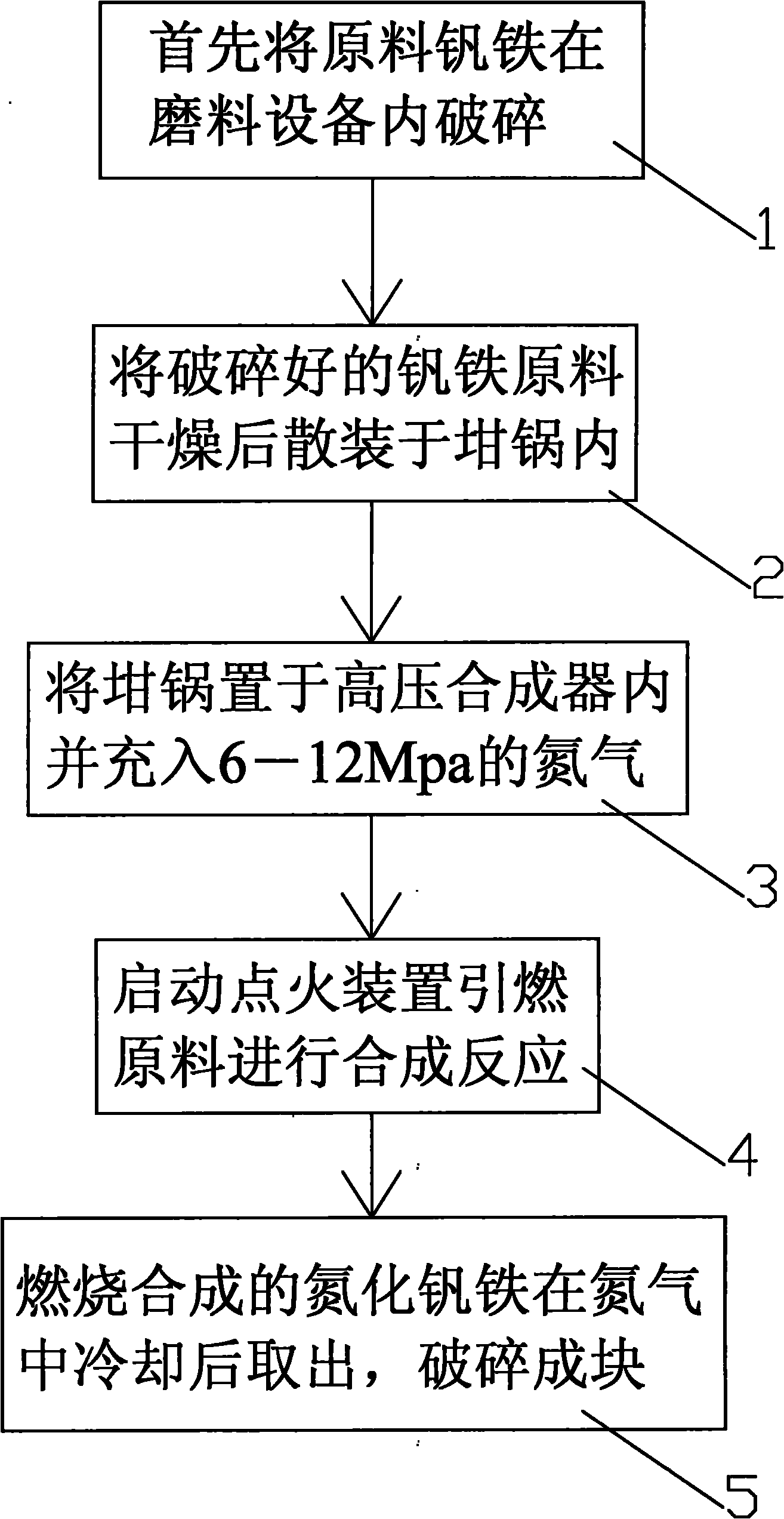

Method used

Image

Examples

Embodiment Construction

[0020] The principle of the method for producing ferrovanadium nitride by the self-propagating high-temperature synthesis process of the present invention is firstly described below.

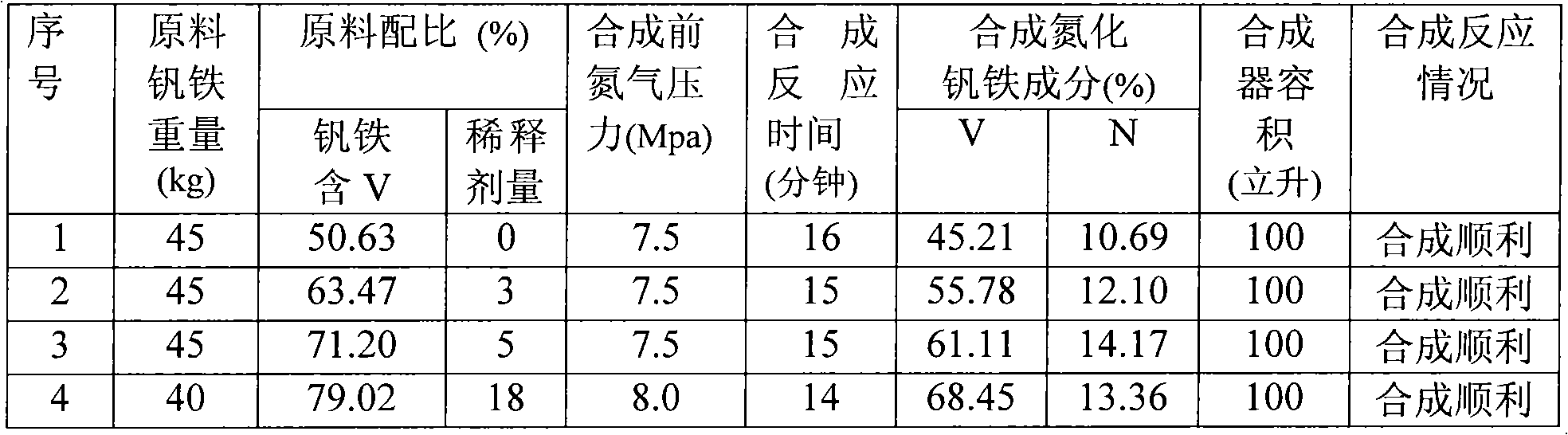

[0021] The raw material that the method for ferrovanadium nitride of the present invention uses can be 50 iron vanadium (FeV50), 60 iron vanadium (FeV60) or 80 iron vanadium (FeV80) and high-purity nitrogen (N 2 ), the adiabatic combustion temperature is mainly calculated by the reaction of V and N, the adiabatic combustion temperature of the vanadium nitrogen compound synthesis reaction is 3500K, it can be seen that the conditions for the synthesis of ferrovanadium nitride by self-propagating high temperature synthesis technology can meet the requirement of Tad>1800K. Although the synthesis heat of FeV50 is low, the adiabatic combustion temperature of the synthesis system can be satisfied by changing the combustion conditions, such as changing the particle size of the raw material, the initial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com