Pole core for lithium ion battery and lithium ion battery using pole core

A lithium-ion battery, pole core technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor bonding force and poor electrolyte wettability, increase volume energy density, and improve ion passage. Efficiency and effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is used to illustrate the battery electrode provided by the present invention, the lithium ion battery using the electrode and their preparation method.

[0037] 1) Preparation of positive electrode

[0038] a: The positive electrode slurry is prepared as follows: 10 grams of polyvinylidene fluoride (Atofina Company) is dissolved in 225 grams of N-methyl-2-pyrrolidone (NMP) solvent to prepare a binder solution, and 15 grams of carbon black (TIMICAL company) was dispersed into the above-mentioned binder solution, and then 500 grams of lithium cobalt oxide was added to the resulting solution, and mixed well to obtain positive electrode active material slurry X1.

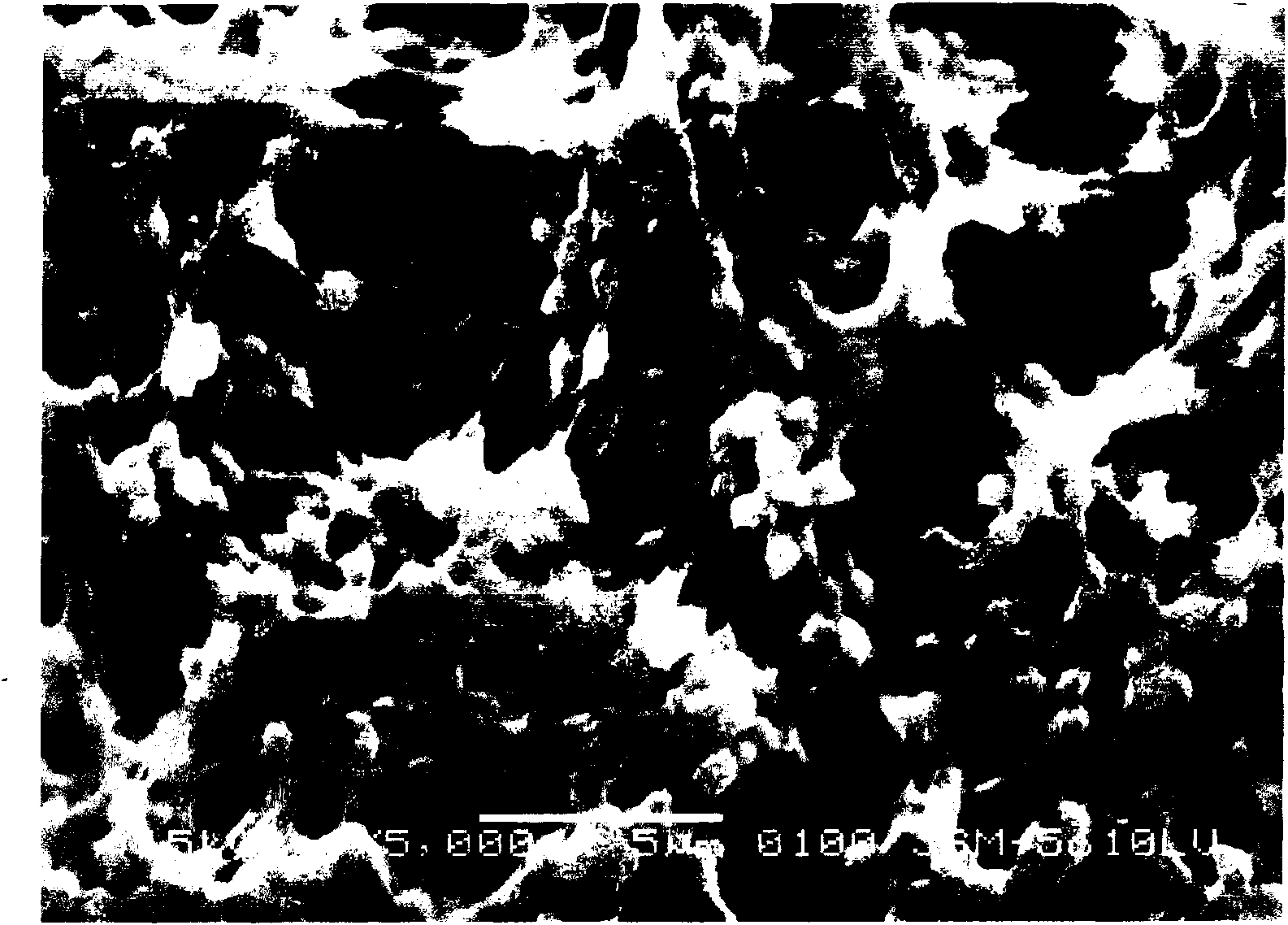

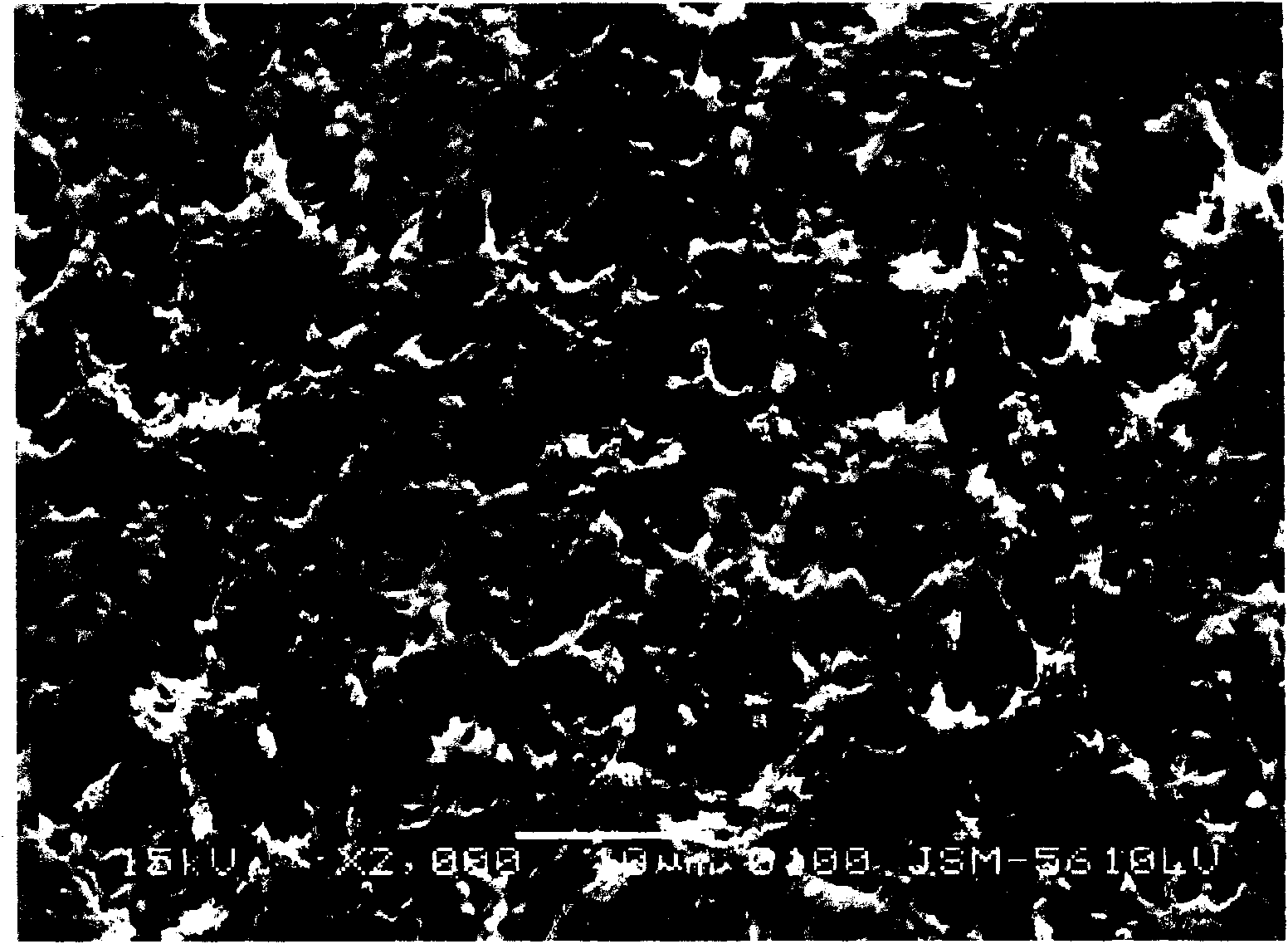

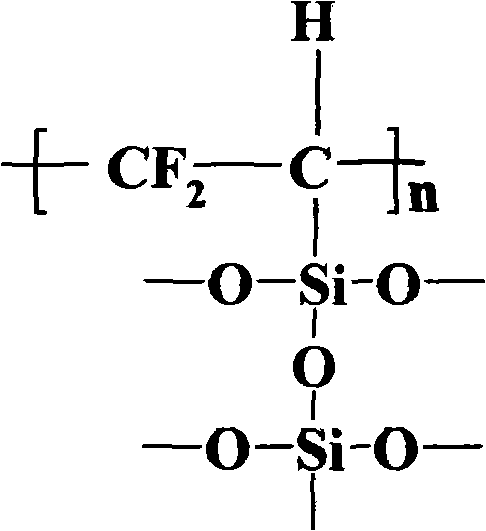

[0039] b: The adhesive layer slurry was prepared by the following method: 8 grams of polyvinylidene fluoride (Atofina Company) was dissolved in 42 grams of ethyl orthosilicate (Beijing Yili Fine Chemicals Co., Ltd.); After the solution was clarified, 500 g of N-methyl-2-pyrrolidone (NMP) solvent wa...

Embodiment 2

[0047] Lithium-ion batteries are prepared according to the method of Example 1, the difference is that the binder layer slurry is prepared by the following method: 10 grams of polyvinylidene fluoride (Atofina Company) is dissolved in 40 grams of tetraethyl orthosilicate (Beijing Yili Fine Chemicals Co., Ltd.), after the solution is clarified, add 500 grams of N-methyl-2-pyrrolidone (NMP) solvent, mix at a speed of 500rpm, and the mixing time is 45 minutes to obtain a homogeneous mixture containing Silicone adhesive paste X3.

[0048] Coat X3 with the surface of the positive and negative electrode materials, form an adhesive layer after curing, and wind the positive and negative electrode sheets covered with the adhesive layer together with the separator to make a pole core, and then follow the procedure in Example 1 Method assembly, obtain lithium ion battery A2.

Embodiment 3

[0050] Lithium-ion batteries are prepared according to the method of Example 1, the difference is that the binder layer slurry is prepared by the following method: 7 grams of polyvinylidene fluoride (Atofina Company) are dissolved in 43 grams of tetraethyl orthosilicate (Beijing Yili Fine Chemicals Co., Ltd.), after the solution is clarified, add 500 grams of N-methyl-2-pyrrolidone (NMP) solvent, mix at a speed of 500rpm, and the mixing time is 45 minutes to obtain a homogeneous mixture containing Silicone adhesive paste X4.

[0051] Coat X4 with the surface of the positive and negative electrode materials, form an adhesive layer after curing, and wind the positive and negative electrode sheets covered with the adhesive layer together with the diaphragm to make a pole core, and then follow the procedure in Example 1 Method assembly, obtain lithium ion battery A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com