Process for preparing temperature-resistant enteric coated enzyme preparation product

A mannanase, enteric coating technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of low temperature resistance, easy to be destroyed by gastric acid, etc., and achieve the effect of wide application and good enteric coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the preparation process of a heat-resistant enteric-coated enzyme preparation product of the present invention, the specific steps are as follows:

[0016] (1) Mix the liquid single-enzyme or compound enzyme preparation with corn starch at a ratio of 1:0.8-1.2, granulate by shaking, and then use a shot blasting machine to round it, and then dry it in a fluidized bed at low temperature to make a granular enzyme preparation .

[0017] (2) Heat-resistant coating powder for self-pharmaceutical use, the components are proportioned by weight: polyol 10%-20%, cellulose sodium 2%-5%, inorganic calcium 2%-5%, and the balance is denatured Starch; self-made enteric-coating powder, the components are proportioned by weight: sodium alginate 25%-50%, modified starch 50%-75%; Mix according to the ratio of 1:1.

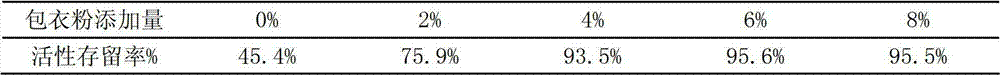

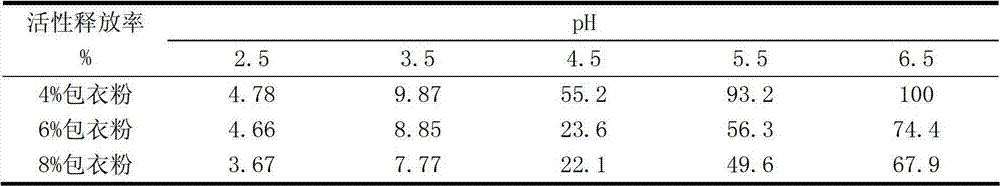

[0018] (3) Dissolve the mixed coating material in pure water at a weight ratio of 2% to 8%, and use boiling fluidized bed equipment to coat and dry the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com