Bi-phthalonitrile resin glass fiber composite material toughened by poly(arylene ether nitrile) and preparation method thereof

A technology of diphthalonitrile resin and diphthalonitrile is applied in the field of diphthalonitrile resin glass fiber composite material and preparation thereof, and can solve the problems of toughening phthalonitrile resin and the like, Achieve the effect of increasing the initial decomposition temperature, increasing the toughness and improving the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

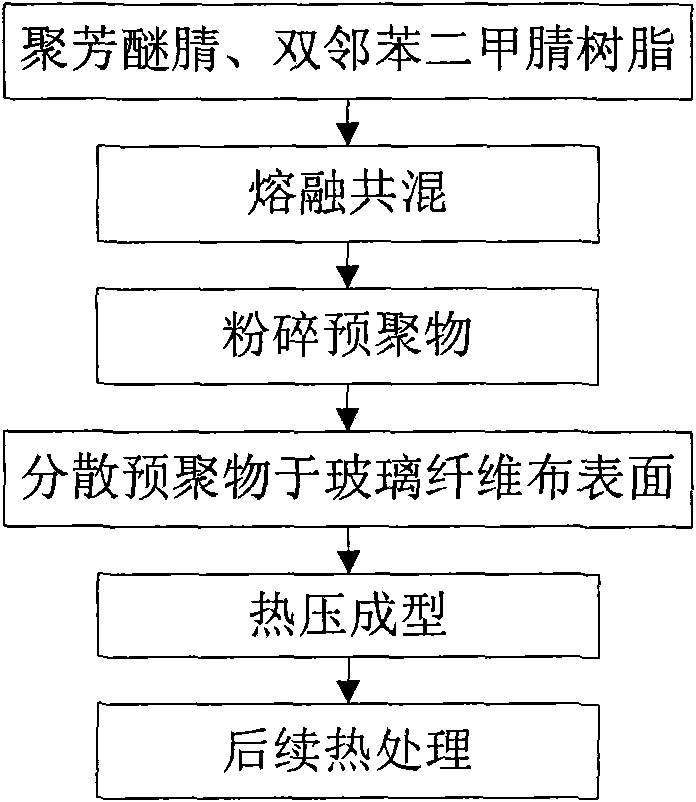

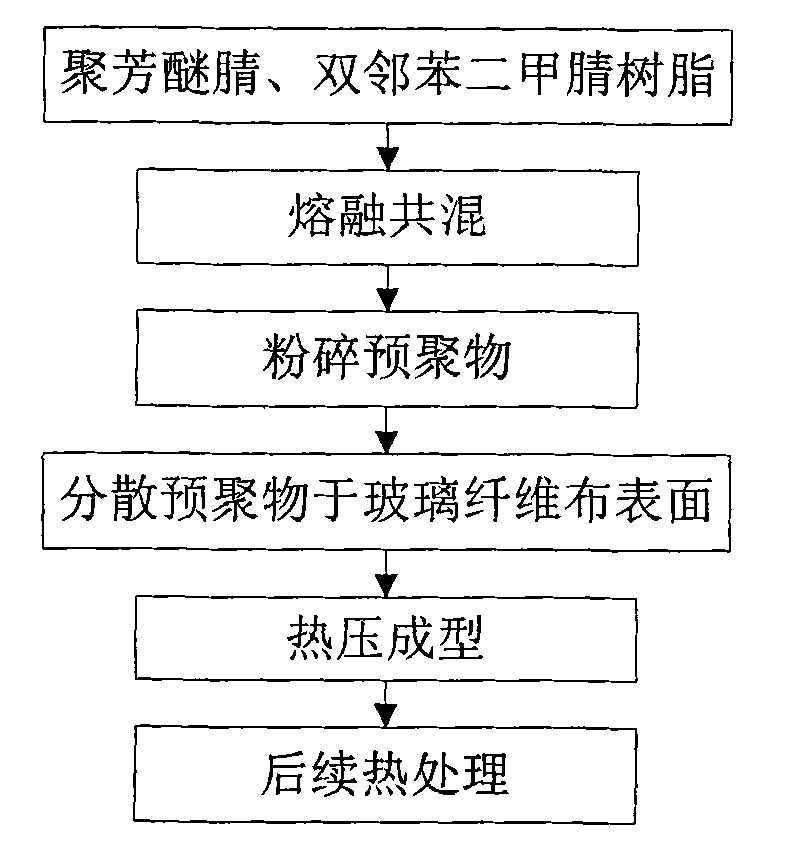

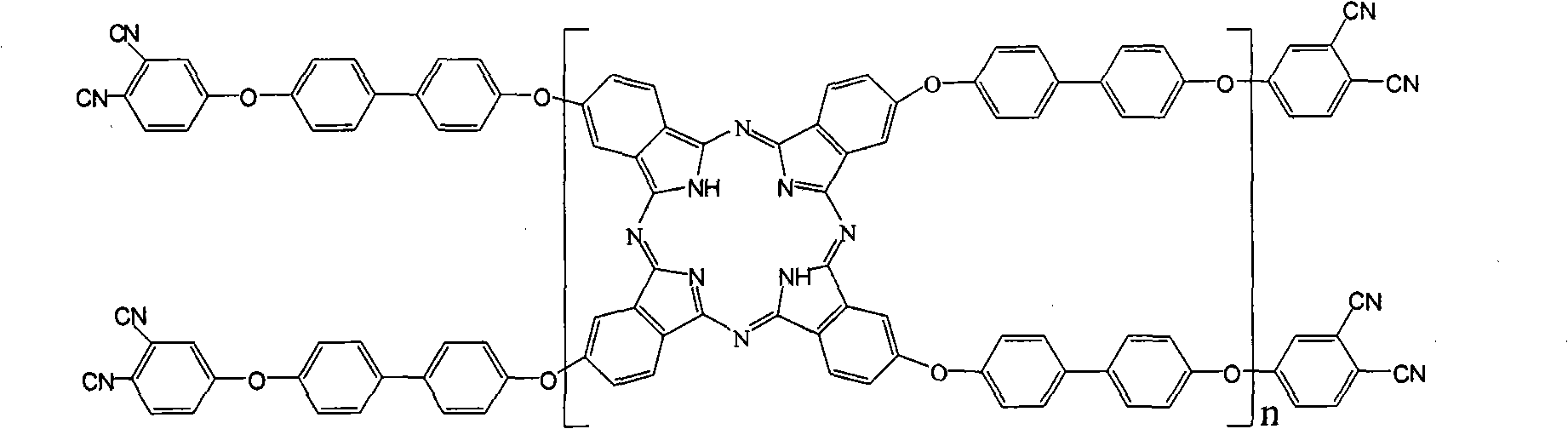

[0026] The preparation method of the polyarylether nitrile toughened bisphthalonitrile resin glass fiber composite material provided by the present invention, such as figure 1 As shown, including the following steps:

[0027] Step 1: According to the mass ratio of polyarylene ether nitrile, bisphthalonitrile resin and glass fiber cloth, weighing the polyarylene ether nitrile powder and bis Phthalonitrile resin and glass fiber cloth.

[0028] Step 2: After heating and melting the bisphthalonitrile weighed in step 1, add polyarylene ether nitrile powder and stir to obtain a molten prepolymer of polyarylene ether nitrile and bisphthalonitrile resin.

[0029] Step 3: After the molten prepolymer of polyarylene ether nitrile and bisphthalonitrile resin obtained in step 2 is cooled, it is pulverized into powder.

[0030] Step 4: Disperse the molten prepolymer powder obtained in Step 3 evenly on the surface of the glass fiber cloth.

[0031] Step 5: Fold the glass fiber cloth treated in step ...

Embodiment 1

[0036] Example 1 The influence of different polyarylether nitrile content on the toughening effect of cured phthalonitrile resin

[0037] (1) The dosage of polyarylene ether nitrile is shown in Table 1:

[0038] Table 1

[0039] raw material

Sample 1

Sample 2

Sample 3

No. 4 sample

Polyarylene ether nitrile

0 grams

2.5g

5 grams

7.5g

Phthalonitrile resin

50 grams

47.5g

45 grams

42.5g

[0040] (2) Production process of polyarylene ether nitrile toughened bisphthalonitrile resin cured product:

[0041] 1. Melt and blend polyarylene ether nitrile and phthalonitrile resin at 250°C for 15 minutes.

[0042] 2. Pour it into the spline mold while it is hot, and heat up and cure according to the following program: 250℃~4 hours, 280℃~4 hours, 300℃~4 hours, 350℃~4 hours, 375℃~6 hours, its performance test The results are shown in Table 2:

[0043] Table 2

[0044]

[0045] The product performance test results in Table 2 show that when the added amount of polyarylene ether nitrile...

Embodiment 2

[0047] Example 2 Preparation of polyarylene ether nitrile toughened glass fiber phthalonitrile resin composite

[0048] (1) Material preparation:

[0049] Polyarylene ether nitrile 7.6 g

[0050] Glass fiber cloth 114 grams (20 layers, 20cm×20cm)

[0051] Phthaliconitrile resin 68.4 g

[0052] (2) Production process:

[0053] 1. Melt and blend polyarylene ether nitrile and phthalonitrile resin at 250°C for 15 minutes, then pulverize into powder after cooling.

[0054] 2. Sieving the powder through a 200-mesh screen, and evenly sprinkle the powder on the glass cloth, each glass cloth is about 3.6 ~ 3.7 grams of powder,

[0055] 3. The hydraulic press is heated to 260°C.

[0056] 4. Superimpose the powdered 20 layers of glass cloth and feed it into the press. The initial pressure is 9MPa, and the pressing procedure is 260℃~6 hours, 280℃~6 hours, 300℃~4 hours.

[0057] The product performance test results are shown in Table 3:

[0058] table 3

[0059] Bisphthalonitrile glass resin fiber comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Initial decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com