Method for producing iron ore concentrate by using Bayer process red muddy sand

A technology of red mud sand and iron concentrate, applied in the direction of alumina/hydroxide, etc., can solve the problems of low iron recovery rate, complex process flow, high investment and operation costs, etc., to reduce iron content, reduce production costs, and increase market capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

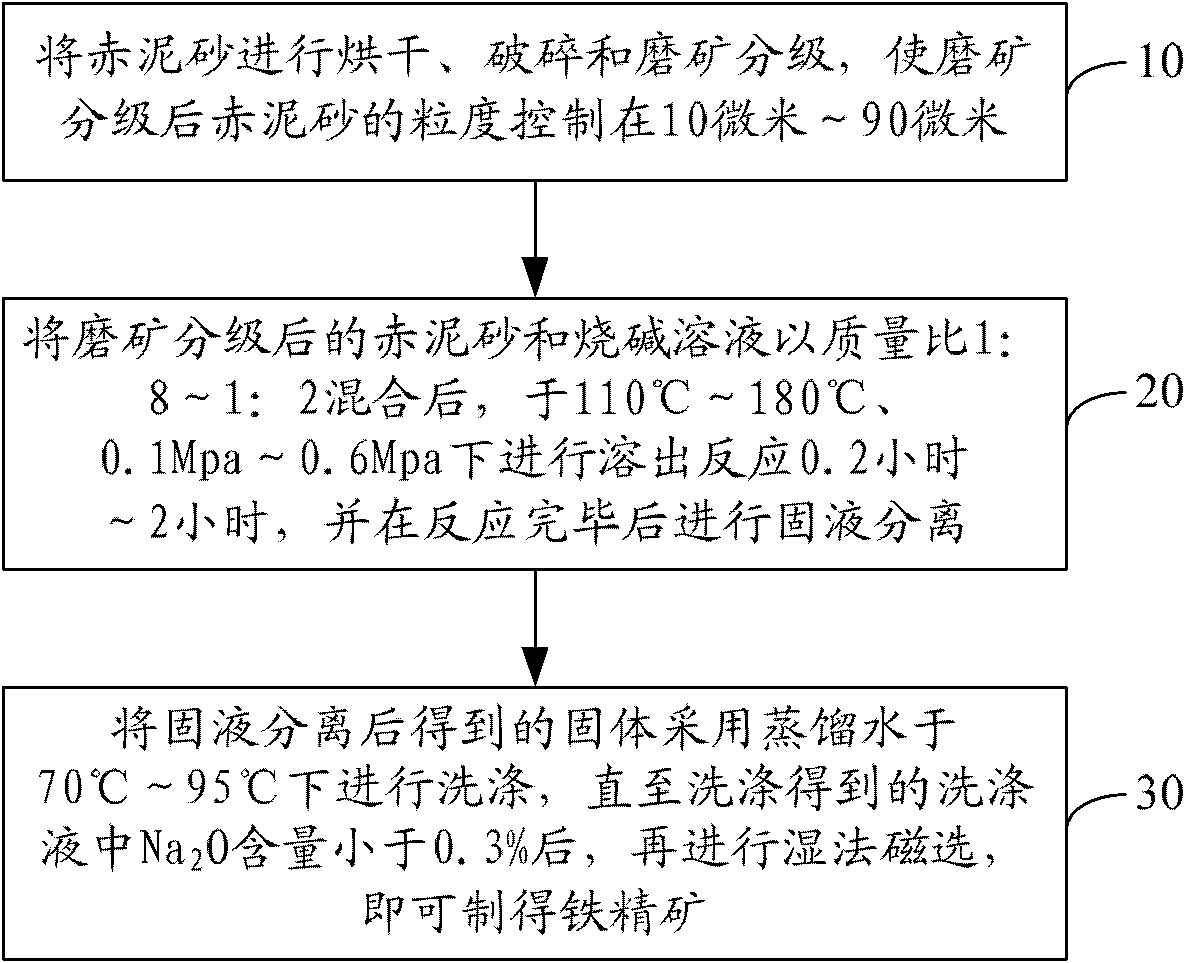

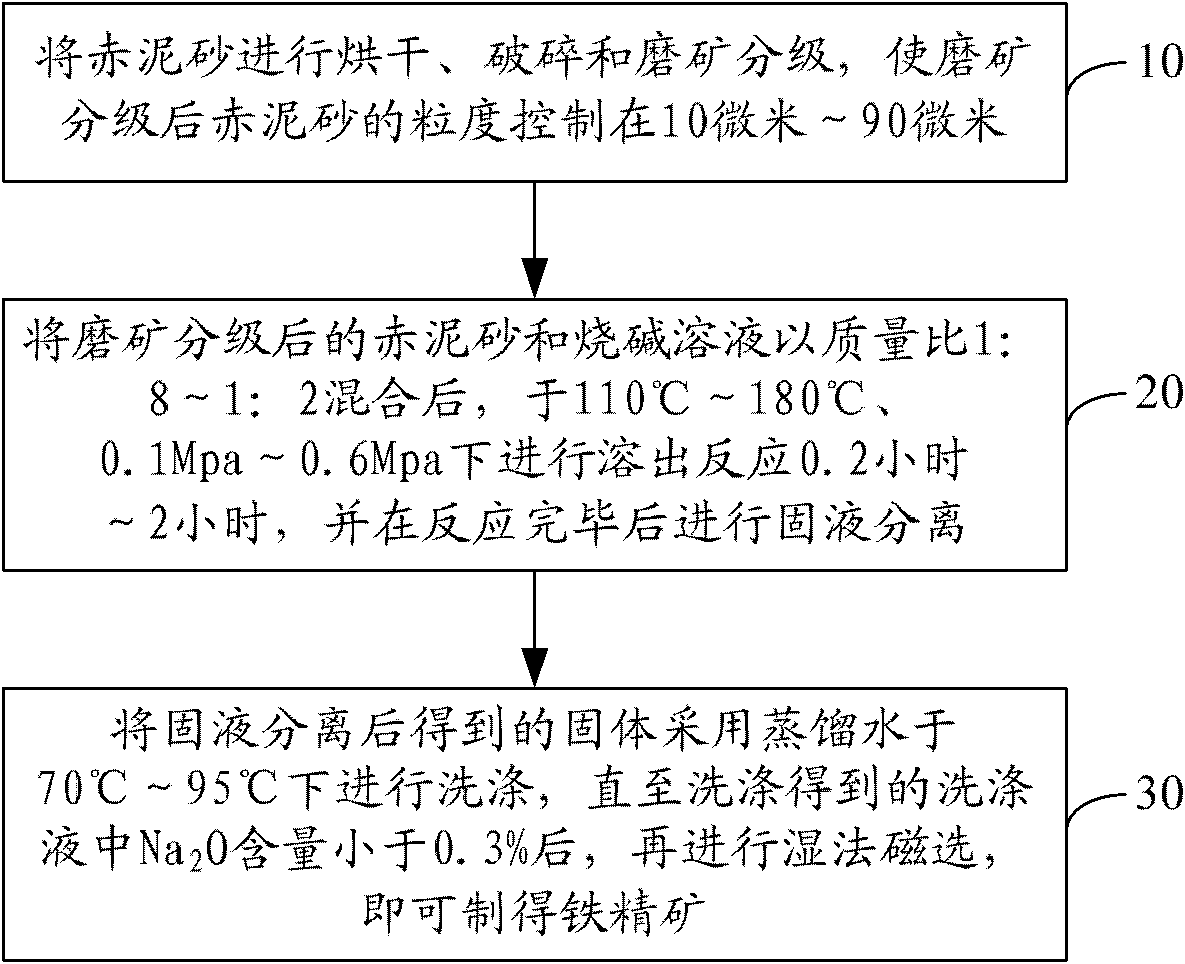

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the total iron content of the red mud sand is 45%. First, the red mud sand is dried, crushed, and ground and graded so that the particle size of the red mud sand after grinding and classification is controlled at 30 microns; After the red mud sand and caustic soda solution are mixed at a mass ratio of 1:3, the dissolution reaction is carried out at 160°C and 0.3Mpa for 0.5 hours, and solid-liquid separation is carried out after the reaction is completed, wherein the content of sodium oxide in the caustic soda solution is 200g / L; finally, use distilled water for the solid obtained after solid-liquid separation, wherein the solid mass ratio of distilled water and solid-liquid separation is 3:1, and wash at 95°C until Na in the washing liquid obtained by washing 2 After the O content is less than 0.3%, wet magnetic separation is carried out under a magnetic field with a magnetic field strength of 7000 gauss to obtain iron concentrate and non-magnetic sl...

Embodiment 2

[0036]In this embodiment, the total iron content of the red mud sand is 47%. First, the red mud sand is dried, crushed, and ground and classified, so that the particle size of the red mud sand after grinding and classification is controlled at 70 microns; After the red mud sand and caustic soda solution are mixed at a mass ratio of 1:5, the dissolution reaction is carried out at 130°C and 0.5Mpa for 2 hours, and solid-liquid separation is carried out after the reaction is completed, wherein the content of sodium oxide in the caustic soda solution is 400g / L; finally, use distilled water for the solid obtained after solid-liquid separation, wherein the mass ratio of distilled water and solid-liquid separation obtained after solid-liquid separation is 5:1, and wash at 70°C until Na in the washing liquid obtained by washing 2 After the O content is less than 0.3%, wet magnetic separation is carried out under a magnetic field with a magnetic field strength of 13000 gauss to obtain ...

Embodiment 3

[0038] In this embodiment, the total iron content of the red mud sand is 50%. First, the red mud sand is dried, crushed, and ground and classified, so that the particle size of the red mud sand after grinding and classification is controlled at 50 microns; After the red mud sand and caustic soda solution are mixed at a mass ratio of 1:4, the dissolution reaction is carried out at 150°C and 0.4Mpa for 1.5 hours, and solid-liquid separation is carried out after the reaction is completed, wherein the content of sodium oxide in the caustic soda solution is 300g / L; finally, use distilled water to obtain the solid after solid-liquid separation, wherein, the mass ratio of distilled water and solid-liquid separation is 4:1, and wash at 80°C until Na in the washing liquid obtained by washing 2 After the O content is less than 0.3%, wet magnetic separation is carried out under a magnetic field with a magnetic field strength of 11000 gauss to obtain iron concentrate and non-magnetic slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com