Chemical vapor diamond deposition device

A chemical vapor deposition and diamond technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., to achieve the effect of increased structure, increased ionization rate, and clear grain facets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the technical solution of the present invention will be described below in conjunction with the accompanying drawings.

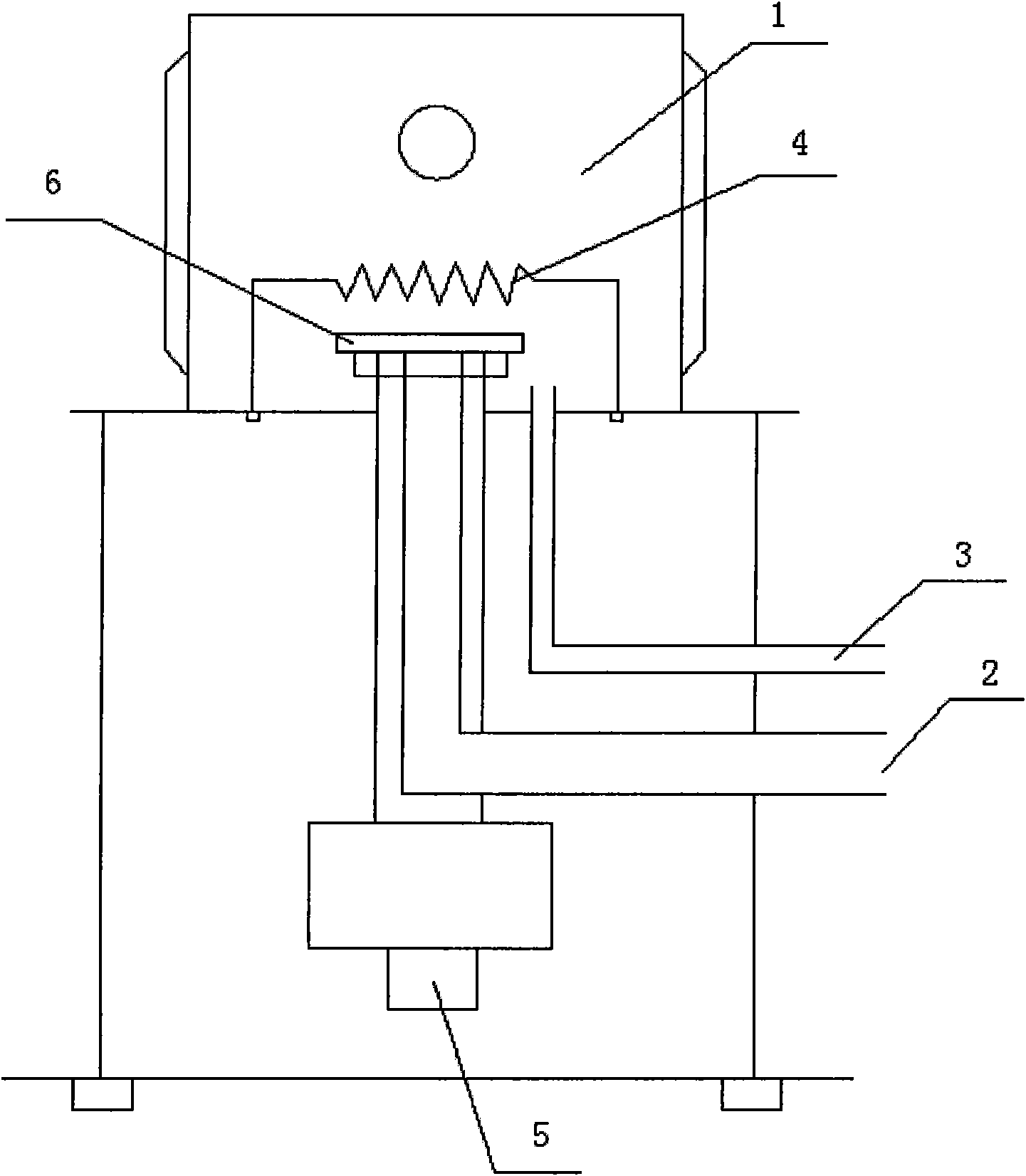

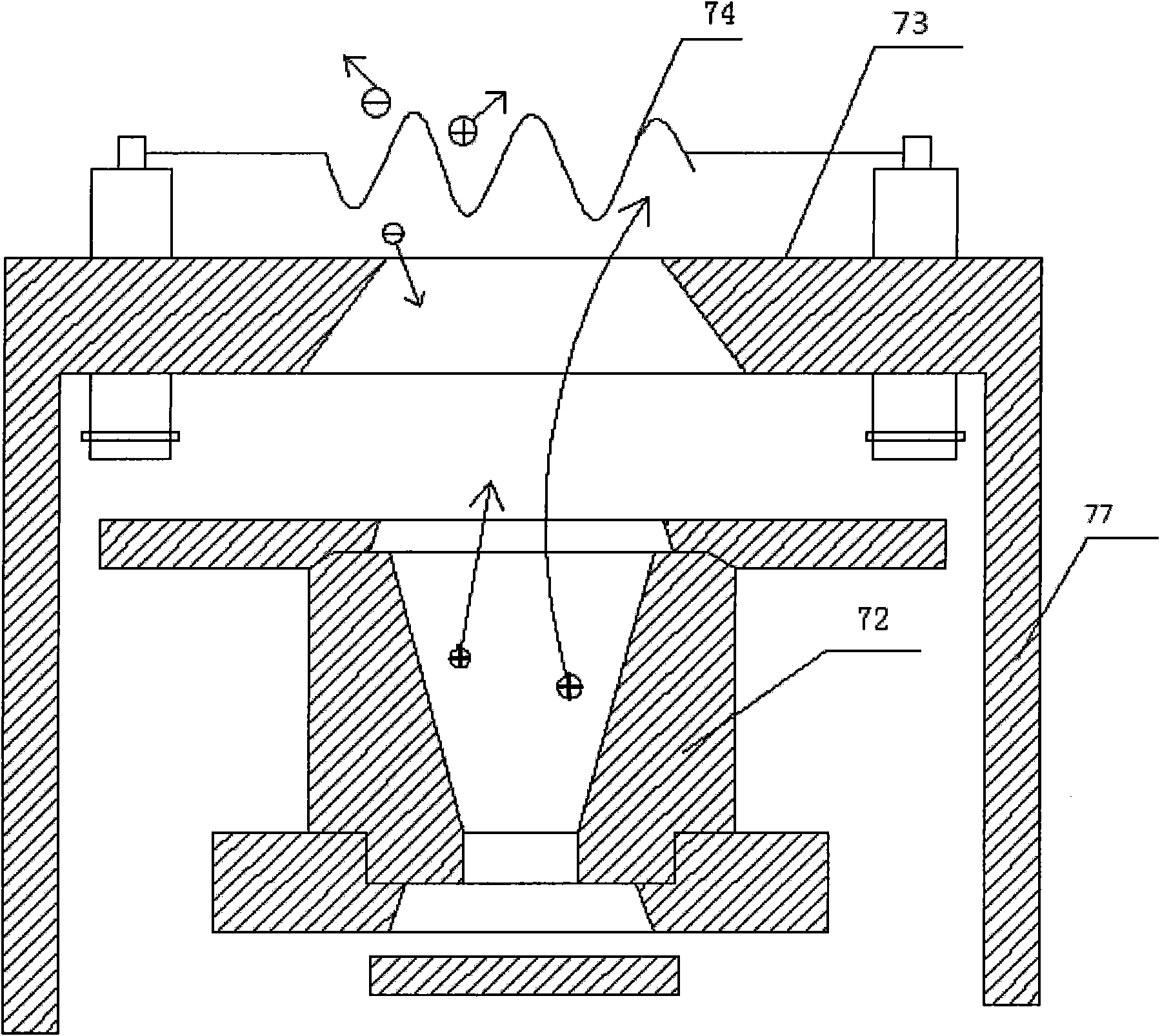

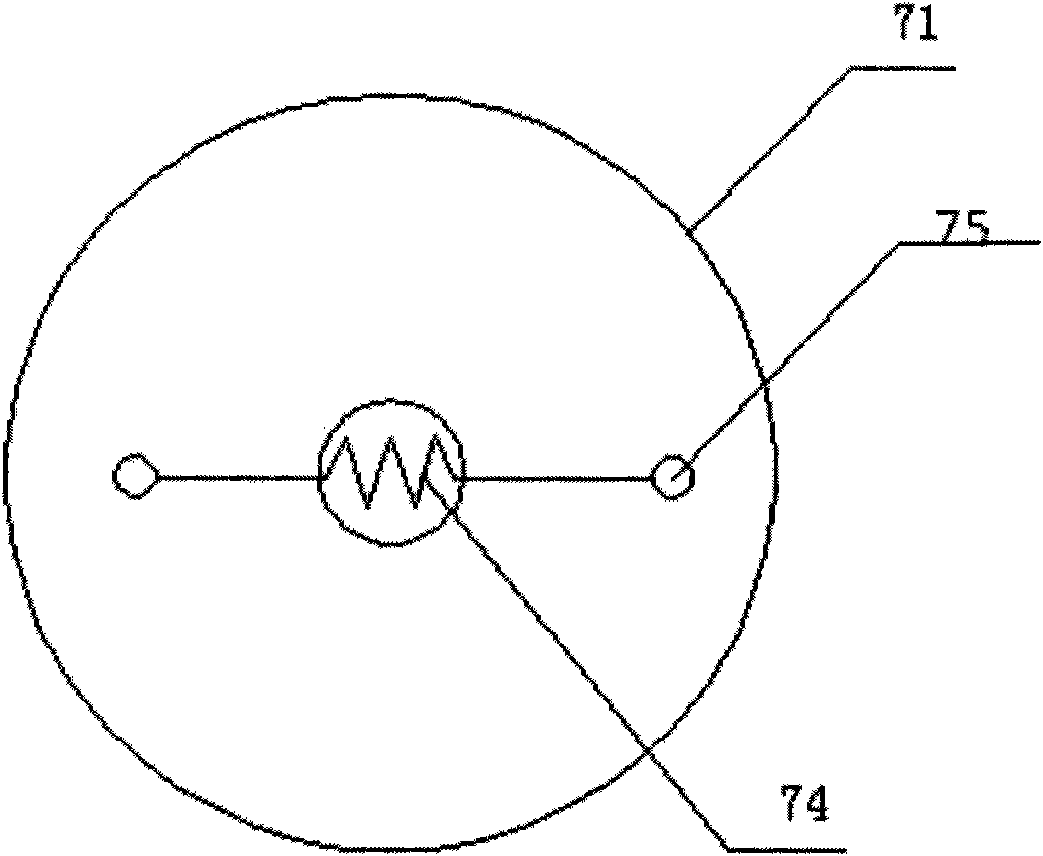

[0013] A chemical vapor deposition diamond device of the present invention is an improvement made for the shortcomings of the existing device that the diamond synthesized contains more amorphous carbon, larger crystal particles, and insufficient compactness. A chemical vapor deposition diamond device of the present invention includes a vacuum chamber 1, a vacuum obtaining system, a cooling system 2, a gas path 3, a hot wire 4, a mechanical rotating mechanism 5, a base 6, a control system and a power supply, etc., and the device also includes A Hall ion source 7, the Hall ion source consists of a shielding cover 71, an anode 72, a magnet 73, a cathode filament 74, a cathode filament lead terminal 75, an air path 76, a bracket 77, a cooling water path 78, and a fastening nut 79 and power supplies. Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com