Clean wet-method solid-liquid two-phase electroreduction lead recovery method

A technology for cleaning wet and electrolytic cells, applied in the field of lead hydrometallurgy for regenerated lead from waste lead materials, can solve the problems of small cathode reduction depth, uneconomical power consumption, low equipment utilization rate, etc., to reduce energy consumption, avoid toxic and harmful Effects of the use of substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

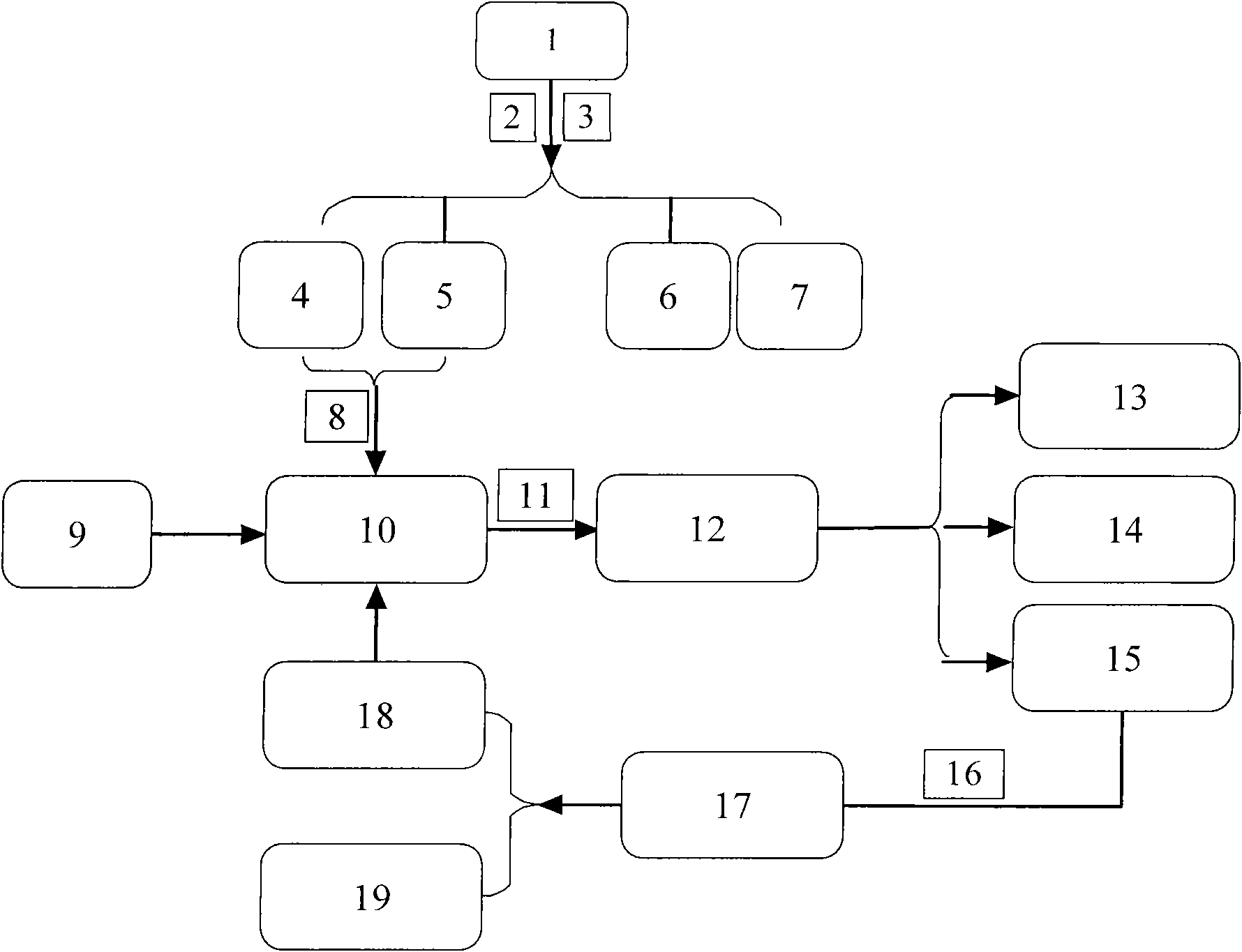

Image

Examples

Embodiment 1

[0032] Take 10 pieces of 12V, 10Ah waste lead-acid batteries for electric vehicles from Tianjin Lantian Hi-Tech Company. The total weight of the battery pack is 42.6 kg. The specific implementation process is as follows:

[0033] 1) After discharging 10 batteries first, put them into a crusher and crush them, and then separate them in the water phase by density difference to obtain lead paste, grids, waste sulfuric acid, separators and shells.

[0034] 2) Put the pressure-filtered lead paste into a ball mill for wet grinding and then screen it with a 60-mesh stainless steel screen. The larger lead paste particles will continue to be transferred to the pulverizer for pulverization until all the lead paste has penetrated Sieve.

[0035] 3) Take 60L of waste sulfuric acid obtained in the process of 1 and adjust its acidity to contain 3mol / L of H 2 SO 4 And 0.1mol / L SnSO 4 Then, the 20 kilograms of lead paste powder obtained by sieving in step 2) and the waste sulfuric acid solution wer...

Embodiment 2

[0041] Take one 12V, 45Ah lead-acid battery from Baoding Fengfan Company, the total weight of the battery pack is 13.5 kg. The specific recovery process is as follows:

[0042] 1) After the battery is first subjected to discharge treatment, and then put into a crusher to be broken, the water phase is separated by density difference to obtain lead paste, grids, waste sulfuric acid, separators and shell.

[0043] 2) Put the pressure-filtered lead paste into a ball mill for wet grinding and then screen it with an 80-mesh stainless steel screen. The larger lead paste particles will continue to be transferred to the pulverizer for pulverization until all the lead paste has penetrated Sieve.

[0044] 3) Take 10L of waste sulfuric acid obtained in process 1 and adjust its acidity to contain 4.2mol / L of H 2 SO 4 And 0.2mol / L SnSO 4 Then, 5.5 kg of lead paste powder and waste sulfuric acid solution obtained by sieving in the second process were mixed uniformly, and kept at a constant tempera...

Embodiment 3

[0050] Take 5 kilograms of lead-containing waste from the lead-acid battery production workshop of Jiangsu Sanhuan Company, pulverize it into powder by a ball mill, and conduct the following lead recovery in sequence:

[0051] 1) After ball milling the lead-containing waste powder, it is sieved with a 60-mesh screen to obtain fine powder, and then 90 L of 27% NaOH solution is added, and the extraction reaction is performed at 90°C. In order to appropriately increase the solubility of lead, the 27% NaOH solution contains 0.2mol / L nitrilotriacetic acid and 0.2mol / L EDTA as co-complexing agents. In this process, the fine powder of lead-containing materials and NaOH undergo a complex dissolution reaction, where Pb(OH) 2 And PbO both form Na with NaOH 2 [Pb(OH) 4 ], after determination, Na 2 [Pb(OH) 4 ] Part of the lead content is 53g / L, and the remaining about 0.3 kg of soil-like sediment, which is mainly composed of silicate-containing soil after analysis.

[0052] 2) When the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com