Energy-saving and antifouling reforming method and system with roof tank and feed pipe

A technology for water supply pipes and water tanks, applied in water supply pipeline systems, water supply devices, water supply main pipelines, etc., can solve the problems of secondary pollution residual chlorine, volatilization waste, loss, etc., to save residual pressure in the pipe network and avoid secondary pollution , Use the effect of economic security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

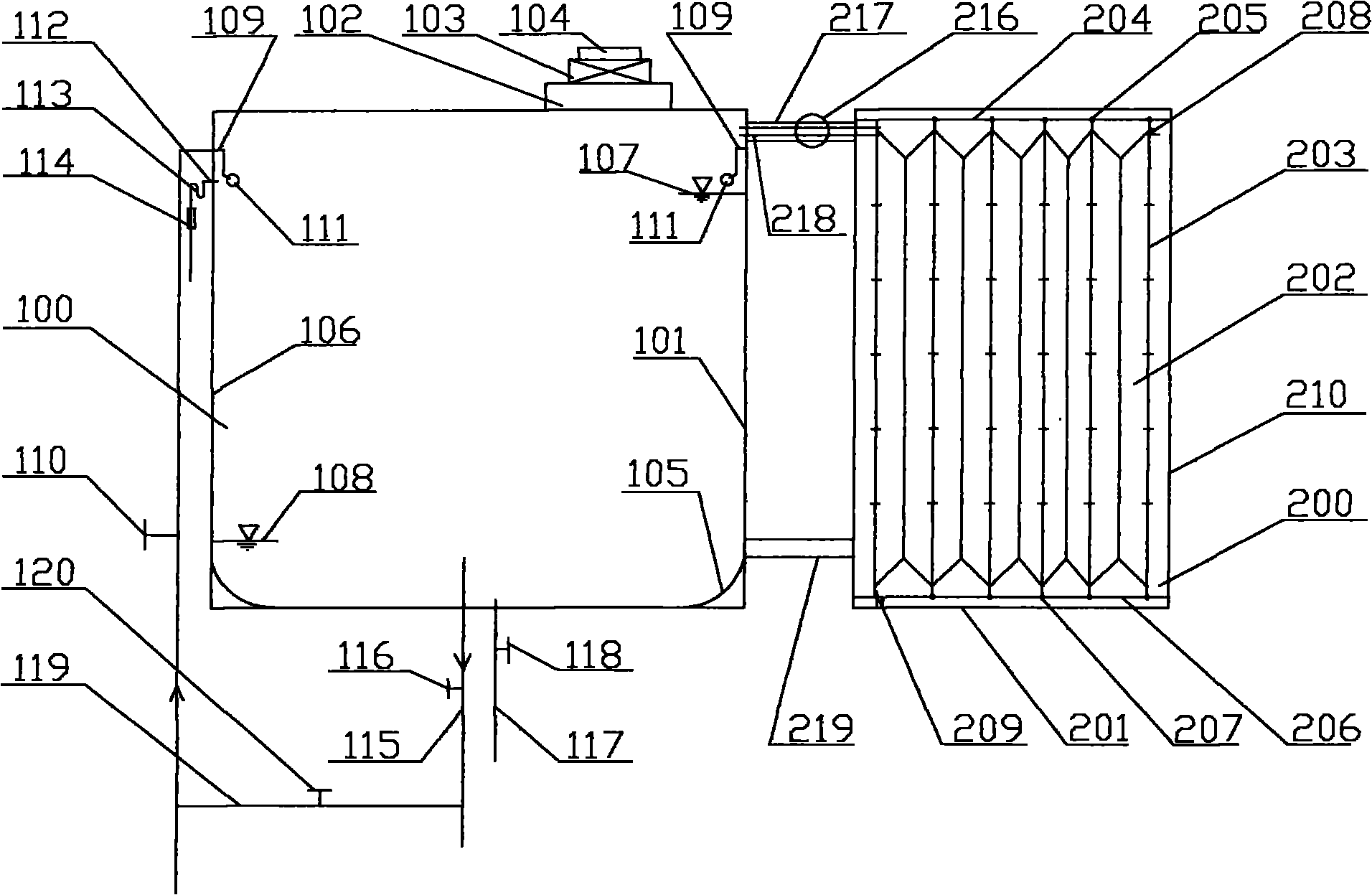

[0047] Embodiment 1 is described by taking a cube-shaped water tank as an example. according to figure 1 As shown, an existing roof water tank and water supply pipe airtight antifouling and energy-saving transformation method is: use food-grade stainless steel or engineering plastics or composite glass fiber reinforced plastics to replace the packaging of the existing water tank, and transform and install it into a water chamber 100 And the air chamber 200 is formed by processing, connecting and installing the connecting breathing sleeve 216 and other components, such as:

[0048] In the water chamber 100, press figure 1 The modification and installation steps shown are as follows: 1. Partition plate 101, arc-shaped diversion bottom baffle 105 and side arc-shaped diversion baffle 106; 2. High water level signal line 107, low water level signal line 108, floating Ball switch assembly 111; 3, manhole assembly 102, exhaust valve assembly 103, air filter assembly 104.

[0049] ...

Embodiment 2

[0052] Embodiment two, illustrate by example of drum, half-drum shape water tank. The breathing air chamber box 200, which is inscribed or centered or separated, is also barrel-shaped or semi-cylindrical. Access, the end of the breathing liner bag group is on the top, the inspection door of the breathing liner bag group is set on the top, and other functional principles are the same as the cube-shaped water tank.

Embodiment 3

[0053] Embodiment three, illustrate by example spherical, pot shape water tank. The breathing air chamber 200, which is centered or separated in it, is also barrel-shaped, and its breathing inner bag set device is just opposite to the cube shape, that is, the breathing air inlet is inserted from the bottom of the breathing inner bag group, and the breathing inner bag The end of the bag group is on the top, and the inspection door of the breathing liner bag group is arranged on the top, and other functional principles are the same as those of the cube-shaped water tank.

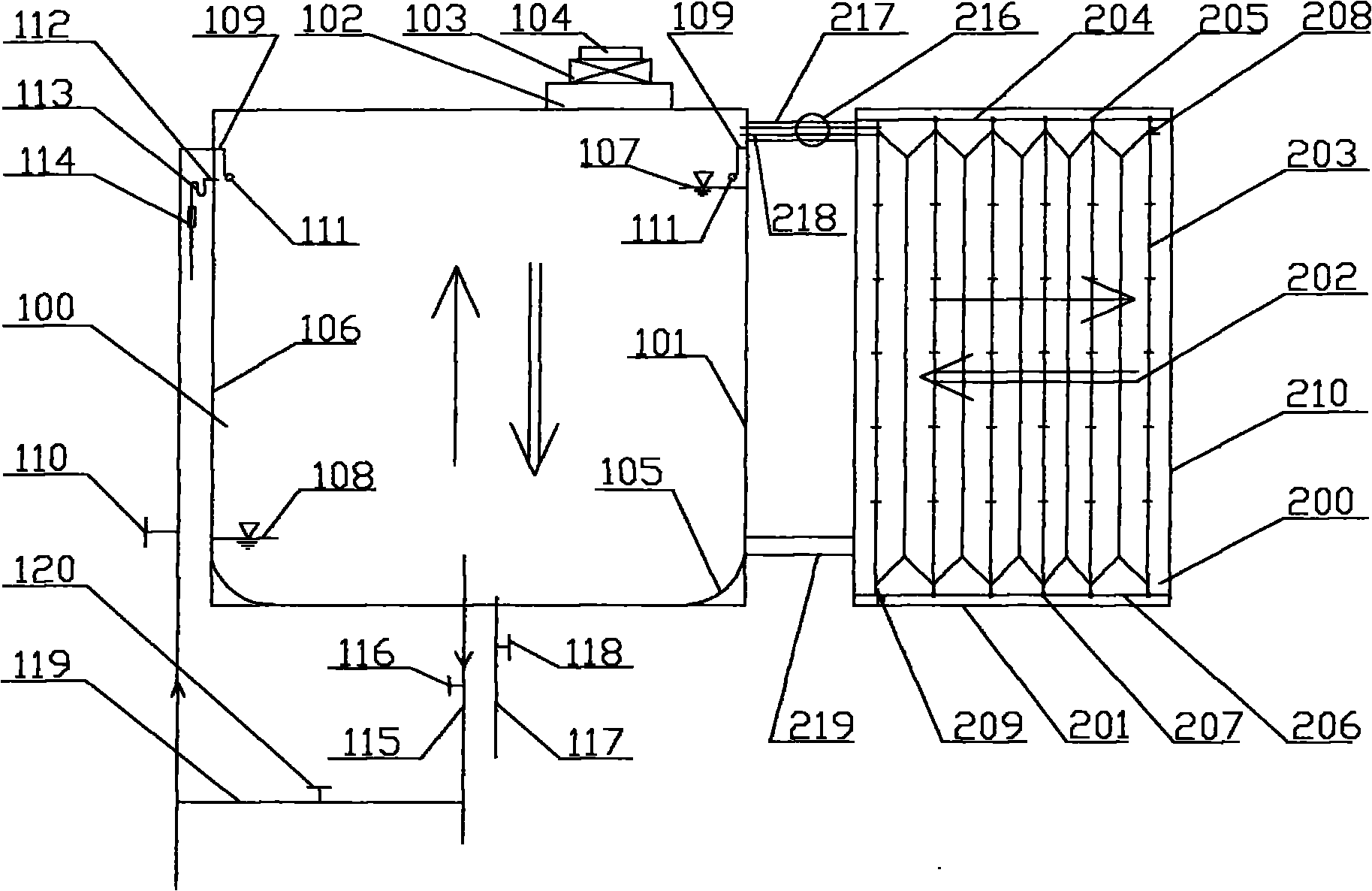

[0054] Implementation of the specific embodiment transformation implementation, such as figure 2 As shown, an implementation of energy-saving and anti-fouling renovation of existing roof water tanks and water supply pipes is as follows:

[0055] according to figure 2Requirements shown: 1. Check, install and connect all parts of the water tank, close the inlet pipe valve 110, the outlet pipe valve 116, open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com