Moxifloxacin hydrochloride glucose injection and preparation method and use thereof

A technology of moxifloxacin hydrochloride and glucose, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve problems such as poor stability of preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

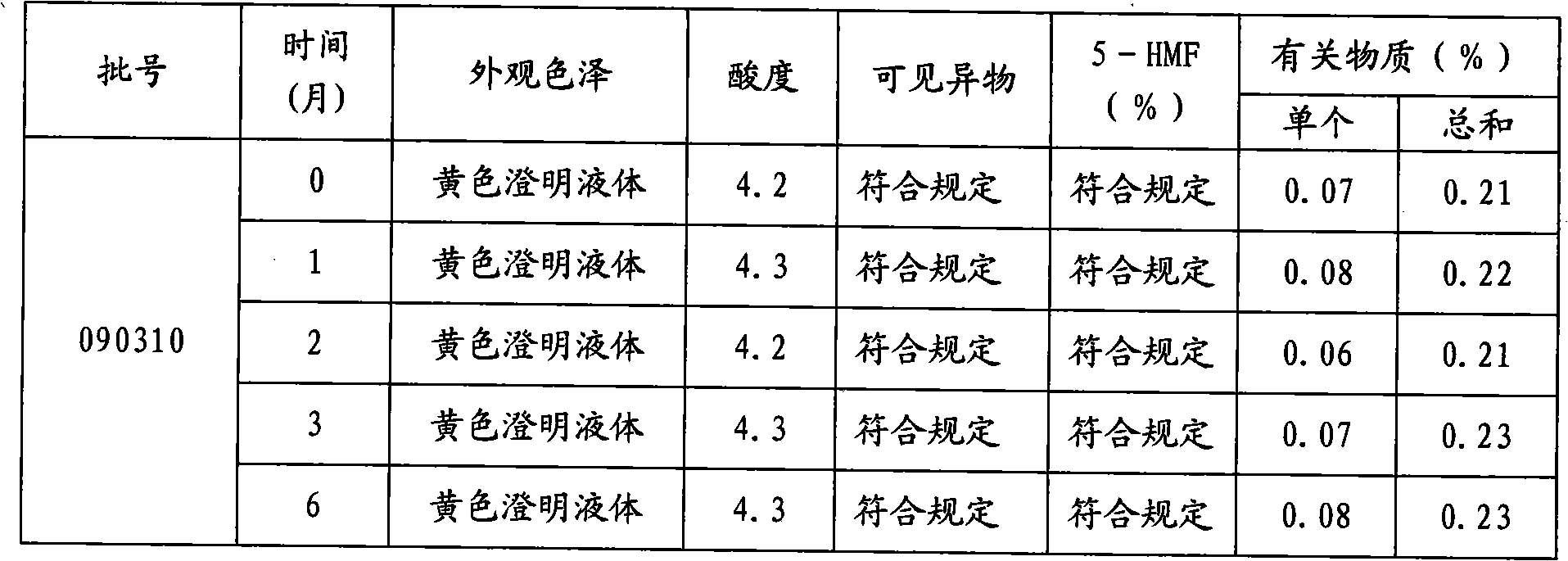

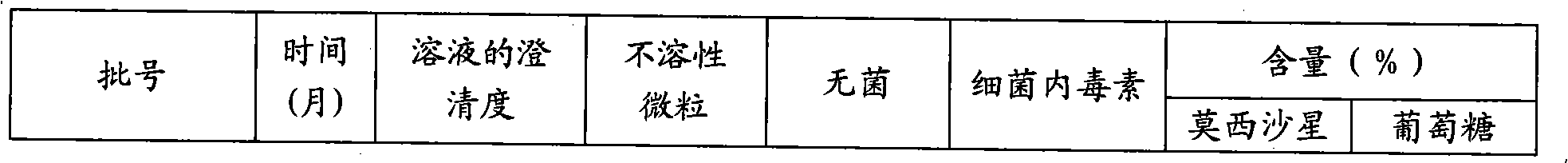

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of moxifloxacin hydrochloride glucose injection (0.4g / 250ml)

[0018] Prescription: Moxifloxacin Hydrochloride 400g (calculated as Moxifloxacin)

[0019] Glucose 12.5kg

[0020] Edetate Calcium Sodium 25g

[0021] Add water for injection to 250L

[0022]

[0023] 1000 bottles

[0024] 1) Obtain qualified moxifloxacin hydrochloride raw materials, glucose and edetate calcium sodium according to the ingredient list;

[0025] 2) Add water for injection with a batch volume of 95% in the batching tank, add the batching amount of glucose, edetate calcium sodium and moxifloxacin hydrochloride, stir to fully dissolve, then oxidize with 1mol / L hydrochloric acid solution or 1mol / L hydroxide Adjust the pH value to 4.0-4.5 with sodium, add medicinal charcoal according to 0.05% (W / V) of the total volume, stir evenly, keep warm at 70°C-80°C for 20 minutes, and...

Embodiment 2

[0032] Embodiment 2: the preparation of moxifloxacin hydrochloride glucose injection (0.4g / 100ml)

[0033] Prescription: Moxifloxacin Hydrochloride 400g (calculated as Moxifloxacin)

[0034] Glucose 5kg

[0035] Edetate Disodium 25g

[0036] Add water for injection to 100L

[0037]

[0038] 1000 bottles

[0039] 1) Obtain qualified moxifloxacin hydrochloride raw materials, glucose and edetate disodium according to the ingredient list;

[0040]2) Add water for injection with a batch volume of 90% in the batching tank, add glucose, edetate calcium sodium and moxifloxacin hydrochloride in batches, stir to fully dissolve, then oxidize with 1mol / L hydrochloric acid solution or 1mol / L hydroxide Adjust the pH value to 4.0-4.5 with sodium, add medicinal charcoal according to 0.05% (W / V) of the total volume, stir evenly, keep warm at 70°C-80°C for 20 minutes, and circulate and filter for more than ...

Embodiment 3

[0047] Embodiment 3: the preparation of moxifloxacin hydrochloride glucose injection (0.4g / 250ml)

[0048] Prescription: Moxifloxacin Hydrochloride 400g (calculated as Moxifloxacin)

[0049] Glucose 12.5kg

[0050] Edetic acid 20g

[0051] Water for injection plus 250L

[0052]

[0053] 1000 bottles

[0054] 1) Obtain qualified moxifloxacin hydrochloride raw materials, glucose and edetate calcium sodium according to the ingredient list;

[0055] 2) Add water for injection with a batch volume of 70% in the batching tank, add the batching amount of glucose, edetic acid and moxifloxacin hydrochloride, stir to fully dissolve, adjust the pH value to 4.0-4.5 with 1mol / L sodium hydroxide, Add medicinal charcoal according to 0.05% (W / V) of the total volume, stir evenly, keep warm at 70°C to 80°C for 20 minutes, and circulate and filter for more than 20 minutes;

[0056] 3) Add water for inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com