Acousto-optic coupling annular gap photocatalytic fluidized bed VOCs degrading device

An acousto-optic coupling and photocatalysis technology, applied in chemical instruments and methods, separation methods, dispersion particle separation, etc., can solve problems such as difficult fluidization, particle agglomeration and channeling, and achieve small oxidation selectivity and wide operating area , Reliable and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

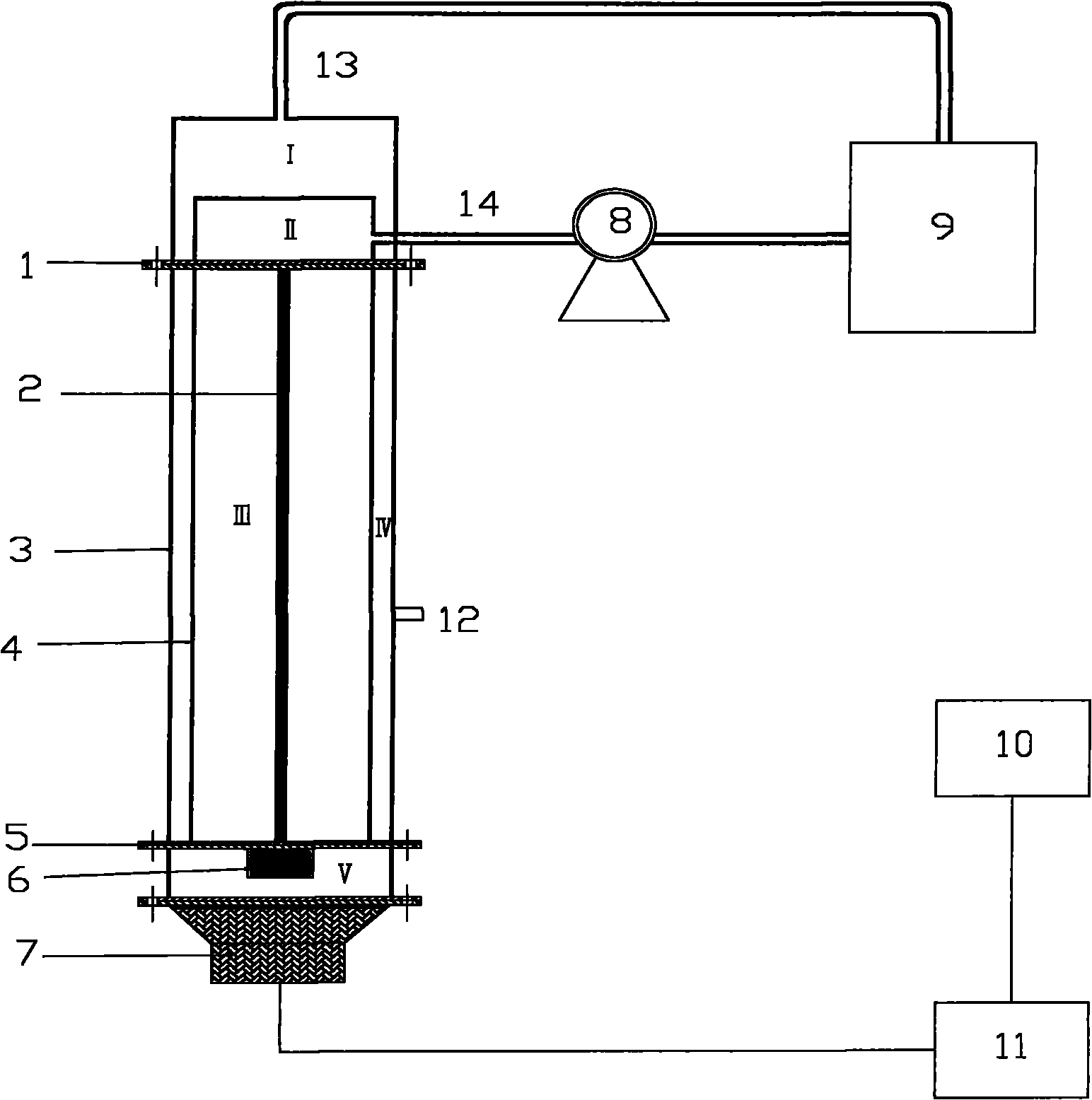

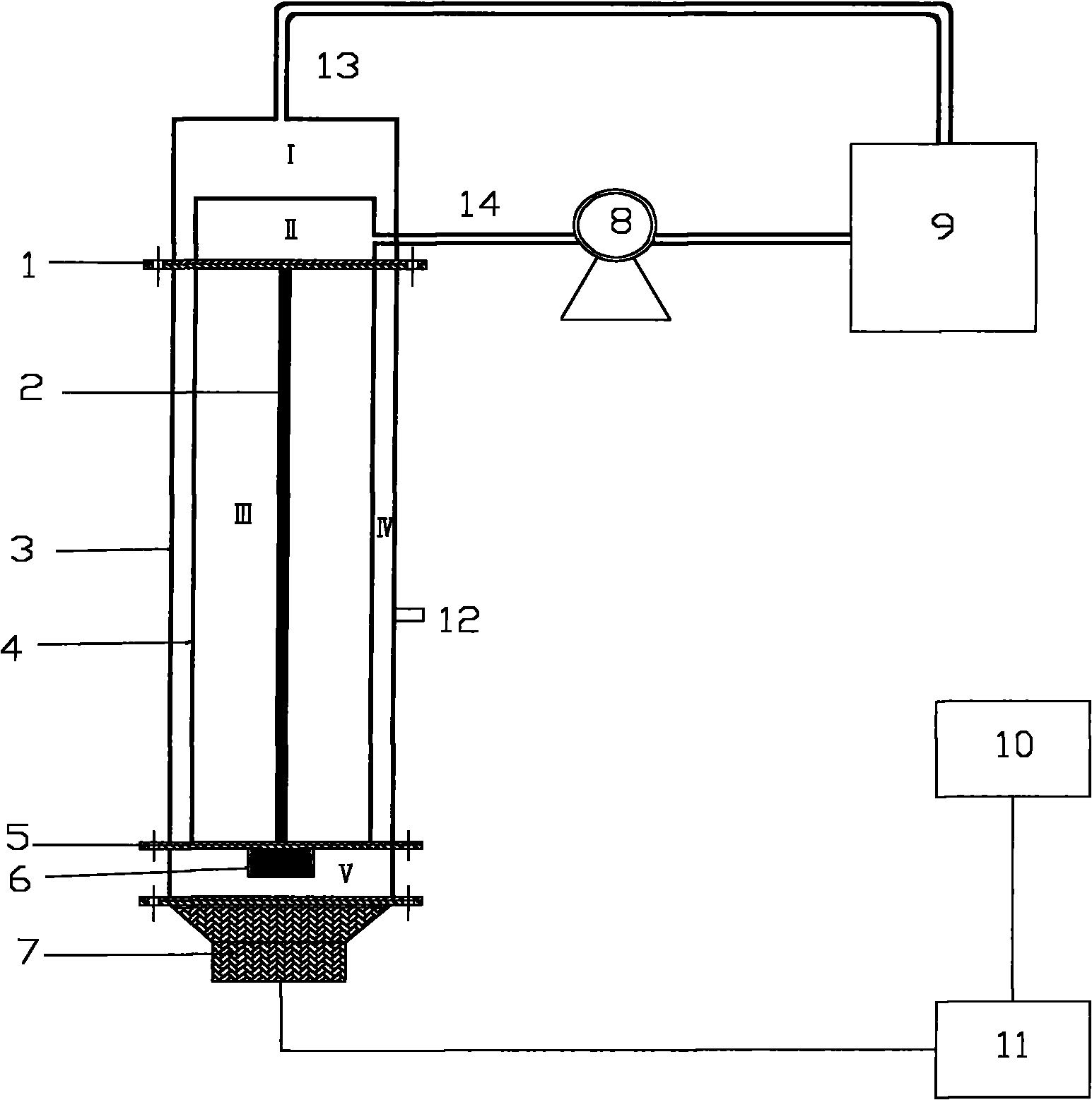

[0011] The structural body of this embodiment includes a gas outlet 13, a gas inlet 14, an air inlet pre-distribution plate (inner ring) and a catalyst particle baffle (outer ring) 1, a plexiglass tube 3, a quartz glass tube 4, an ultraviolet lamp 2, Reactor inlet distribution plate 5, lamp installation base 6, test port 12, speaker 7, fan 8, gas configuration device 9, sound wave amplifier 11 and signal generator 10, as well as gas collection chamber 1, gas premix chamber II, Intake channel III, annular fluidized bed reaction zone IV and gas distribution chamber V; each device or component is combined in principle and reliability to form a columnar nested photocatalytic degradation device or reactor for gaseous pollutant VOCs; the device's Functional structure: the gas outlet 13 is located at the top center of the reactor gas collection chamber I, and the pipe diameter The gas inlet 14 passes through the side wall of the gas collection chamber I and is connected to the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ring diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com