Method for treating sewage by using biological membrane and equipment thereof

A biofilm and biofilm carrier technology, applied in the field of water treatment, can solve the problems of difficult treatment, unfavorable large-area water application, high operation and management costs, low oxygen supply cost, low operation and preparation cost, and continuous purification effect. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

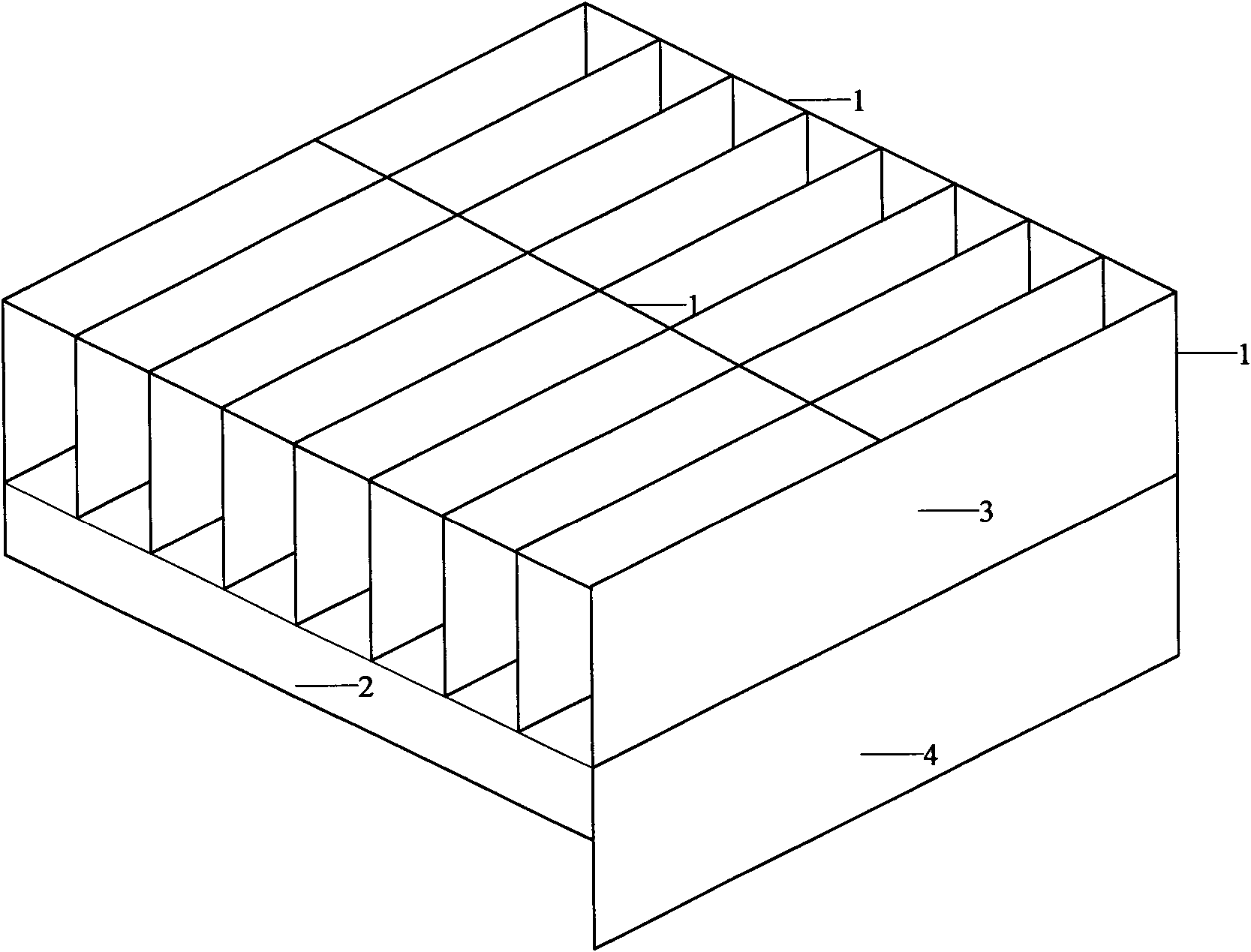

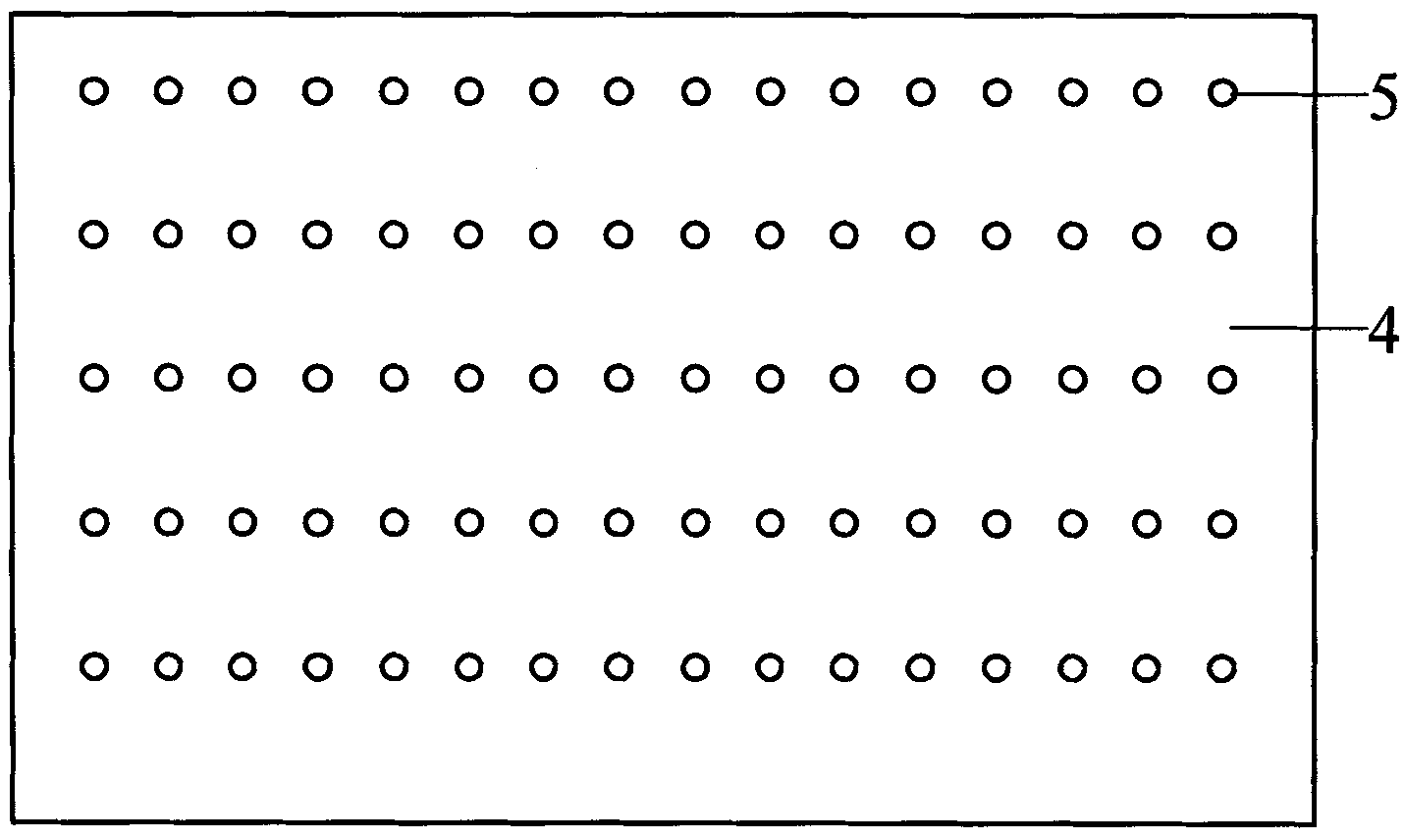

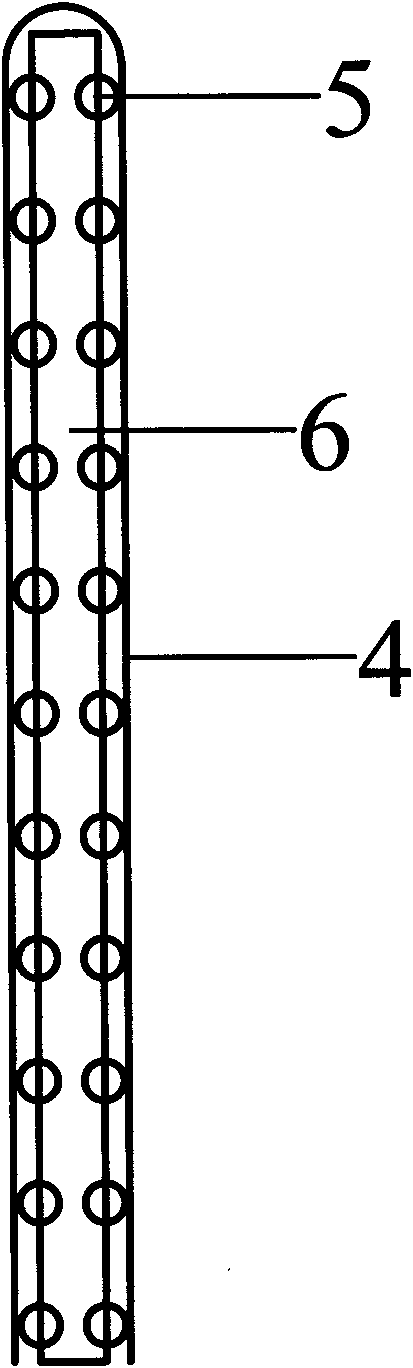

Method used

Image

Examples

Embodiment 1

[0026] Cut the 20cm-wide microfiber fabric into 15cm-long cloth pieces, and evenly paste zeolite particles with a particle size of about 1cm on both sides to construct a suspended biofilm mass transfer and carrier unit; use angle steel to construct a length, width and height of 30cm respectively , 25cm, 50cm rectangular frame; the frame is set around a plastic box (length, width and height: 25cm, 20cm, 40cm) filled with domestic sewage, and the suspended biofilm unit is first aerated in the domestic sewage by traditional methods to hang the membrane, and the membrane is successfully installed Finally, the upper end of each unit cloth is fixed with iron wire and hung on the frame, and the lower end of the cloth is immersed in the water in the plastic box by 5 cm. A total of 15 units are evenly suspended above the sewage, and the interval between the units is about 1-2 cm. The domestic sewage in the plastic box is treated in sequential batch. The domestic sewage used is diluted ...

Embodiment 2

[0028] Cut the microfiber fabric and non-woven fabric with a width of 20cm into 15cm-long cloth pieces, evenly paste sand particles with a particle size of about 1cm on both sides of the non-woven fabric, and wrap two pieces of microfiber fabric with the non-woven fabric. And fix them together with thread sutures to build a suspended biofilm mass transfer and carrier unit; use angle steel to build a rectangular frame with a length, width, and height of 30cm, 25cm, and 50cm; the frame is set in a plastic box filled with domestic sewage (length, width, and height: 25cm, Around 20cm, 40cm), the suspended biofilm unit is first aerated in the domestic sewage with the traditional method to hang the film. After the film is successfully installed, the upper end of each unit cloth is fixed with iron wire, hung on the frame, and the lower end of the cloth is 5cm into the plastic box. In the water, a total of 15 units are evenly suspended above the sewage, and the interval between the uni...

Embodiment 3

[0030] Cut the 20cm wide microfiber fabric into 15cm long cloth pieces, roughen the surface of the semi-rigid plastic sheet, cut it into the same size, wrap the two pieces of microfiber fabric with the plastic sheet, and fix them together with thread , to construct a suspended biofilm mass transfer and carrier unit; use angle steel to construct a rectangular frame with a length, width and height of 30cm, 25cm, and 50cm; the frame is set around a plastic box (length, width, and height: 25cm, 20cm, 40cm) filled with domestic sewage, The suspended biofilm unit is first aerated in the domestic sewage with the traditional method to hang the film. After the film is successfully hung, the upper end of each unit cloth is fixed with an iron wire and hung on the frame. 15 units are evenly suspended above the sewage, with an interval of about 1-2cm between the units. The domestic sewage in the plastic box is treated in a sequential batch manner. The removal rate of COD and ammonia nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com