BaTiO3-based PTC thermal sensitive ceramic material and preparation method thereof

A heat-sensitive ceramic, bi2o3 technology, applied to resistors with a positive temperature coefficient, etc., can solve problems such as the reduction of the efficiency of the Curie temperature increase, the limited increase of the Curie temperature, and the increase of the room temperature resistivity of the ceramic sample. , to achieve the effect of low room temperature resistivity, good repeatability and good PTC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

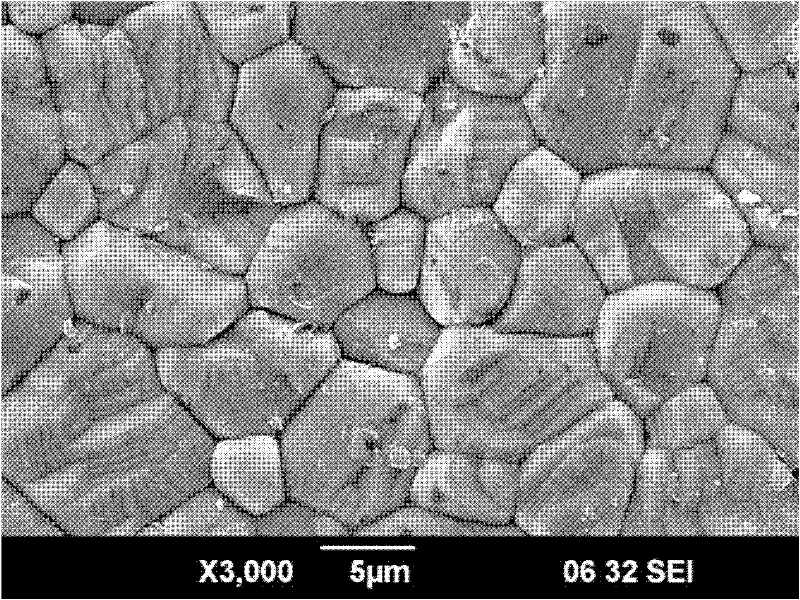

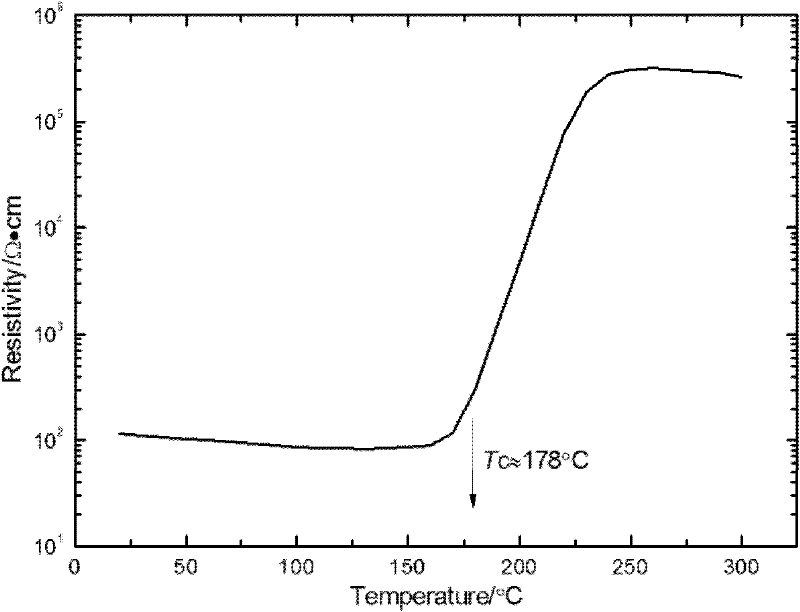

Image

Examples

Embodiment 1

[0023] Step 1: Weigh BaCO according to the molar ratio of 0.96:0.002:0.002 3 、 Bi 2 o 3 , and K 2 CO 3 , mixed to form mixture A, then, weigh TiO 2 , the TiO 2 Mix with mixture A according to the molar ratio of 1:1 to form mixture B;

[0024] Step 2: Weigh the mixture B obtained in Step 1 according to the mass ratio of 1:1:2.5, as well as zirconium balls and deionized water, place it in a ball mill jar for ball milling for 10 hours, move it into an oven, and dry it at 100°C. Then, transfer it to a high-temperature electric furnace and keep it warm at 1100°C for 2 hours to form a pre-mixture, which is set aside;

[0025] Step 3: Take the main material mixture B as 1 mol, and weigh Nb accounting for 0.3 mol% of the main material according to the molar percentage 2 o 5 , accounting for 0.2mol% of the main material Y 2 o 3 , 0.02mol% Mn(NO 3 ) 2 , and 0.2mol% of Sb in the main material 2 o 3 , then, the above Nb 2 o 5 , Y 2 o 3 , Mn(NO 3 ) 2 , and Sb 2 o 3 Ad...

Embodiment 2

[0033] Step 1: Weigh BaCO according to the molar ratio of 0.98:0.001:0.001 3 、 Bi 2 o 3 , and K 2 CO 3 , mixed to form mixture A, then, weigh TiO 2 , the TiO 2 Mix with mixture A according to the molar ratio of 1:1 to form mixture B;

[0034] Step 2: Weigh the mixture B, zirconium balls and deionized water obtained in step 1 according to the mass ratio of 1:1:2.5, place it in a ball mill jar and mill it for 10 hours, then move it into an oven, dry it at 100°C, and then , transferred to a high-temperature electric furnace and kept at 1200°C for 2 hours to form a pre-mixture, and set aside;

[0035] Step 3: Take the main material mixture B as 1 mol, and weigh Nb accounting for 0.15 mol% of the main material according to the molar percentage 2 o 5 , 0.1mol% Y 2 o 3 , 0.025mol% Mn(NO 3 ) 2 , and 0.1mol% Sb 2 o 3 , then, the above Nb 2 o 5 , Y 2 o 3 , Mn(NO 3 ) 2 , and Sb 2 o 3 Add to the premix obtained in step 2, and form the complete batch after mixing;

...

Embodiment 3

[0043] Step 1: Weigh BaCO according to the molar ratio of 0.99:0.005:0.005 3 、 Bi 2 o 3 , and the K 2 CO 3 , mixed to form mixture A, then, weigh TiO 2 , the TiO 2 Mix with mixture A according to the molar ratio of 1:1 to form mixture B;

[0044] Step 2: Weigh the mixture B, zirconium balls and deionized water obtained in step 1 according to the mass ratio of 1:1:2.5, place it in a ball mill jar and mill it for 10 hours, then move it into an oven, dry it at 100°C, and then , transferred to a high-temperature electric furnace and kept at 1230°C for 2 hours to form a pre-composite material for later use;

[0045] Step 3: Take the main material mixture B as 1 mol, and weigh Nb accounting for 0.1 mol% of the main material according to the molar percentage 2 o 5 , 0.05mol% of Y 2 o 3 , 0.02mol% Mn(NO 3 ) 2 , and 0.15 mol% Sb 2 o 3 , then, the above Nb 2 o 5 , Y 2 o 3 , Mn(NO 3 ) 2 , and Sb 2 o 3 Add to the premix obtained in step 2, and form the complete batch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com