Method for preparing nanometer nitro celluloses

A technology of nitrocellulose and nanocellulose, which is applied in the field of preparation of nanometer nitrocellulose, can solve the problems of poor stability of nitrocellulose, pollution in nitrocellulose production, complicated post-treatment and reuse of waste acid, etc., and achieves shortened nitration time, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of nanocellulose suspension

[0024] Cotton cellulose powder was ultrasonically pretreated in an ice bath for 15 minutes, filtered and dried for later use.

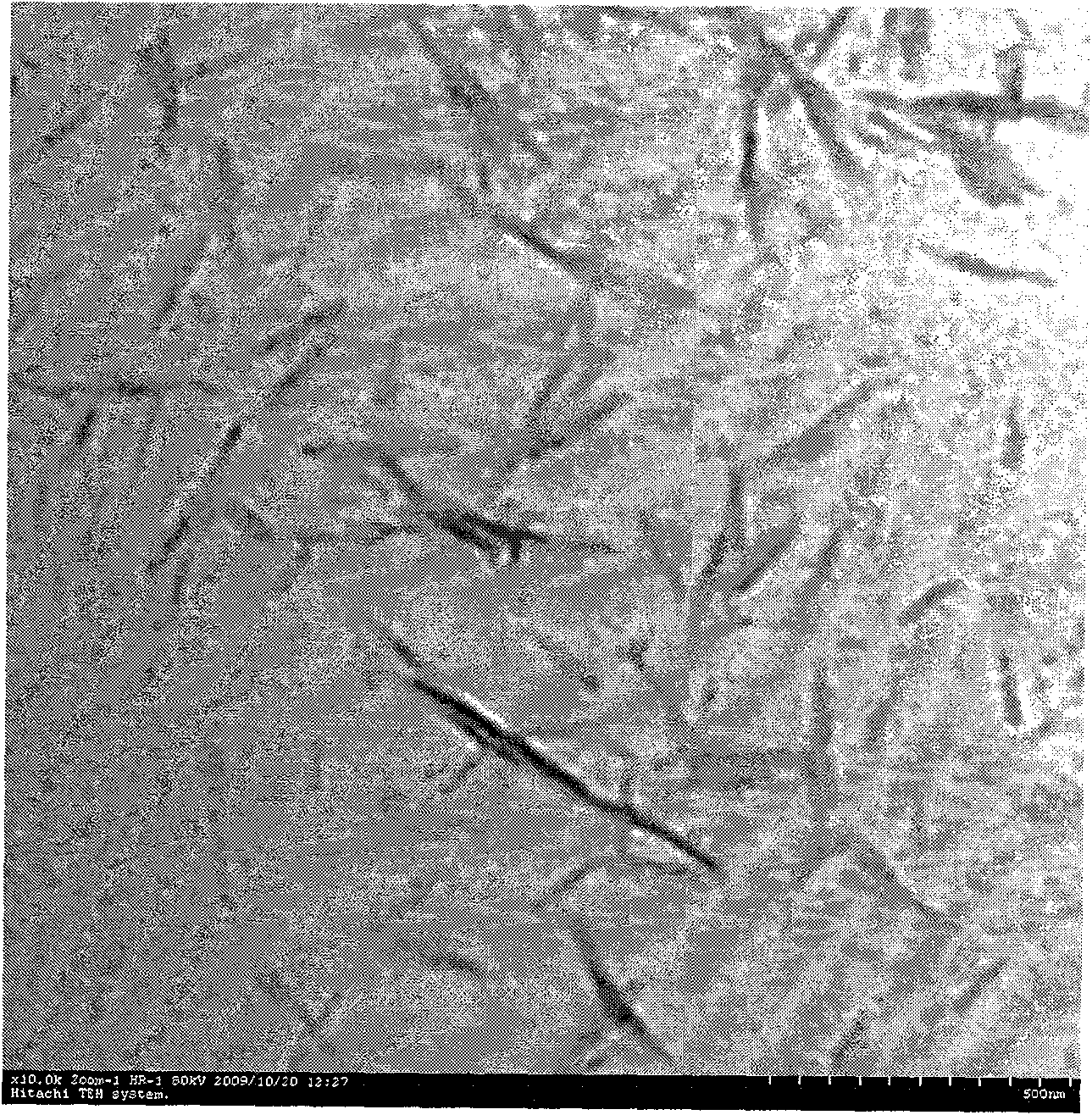

[0025] Immerse 0.5g of the above-mentioned cellulose powder accurately weighed in 8.75ml of sulfuric acid solution with a concentration of 64wt%, stir and react in a water bath at 45°C for 1h, then add 10 times the volume of deionized water to dilute the reaction solution; the diluted reaction The solution was centrifuged at 8000 rpm; the suspension was dialyzed in deionized water for 24 hours until the pH value was the same as that of the deionized water used. The molecular weight cut-off of the dialysis bag used is 8000-14000; finally, after ultrasonic dispersion with a power of 150w for 15 minutes, a stable suspension of nanocellulose whiskers is obtained, wherein the nanocellulose whiskers have a diameter of 20-30nm and a length of 150- 250nm. The morphology of the prepared nanocellulose whisk...

Embodiment 2

[0029] (1) Preparation of nanocellulose suspension

[0030] Cotton cellulose powder was ultrasonically pretreated in an ice bath for 15 minutes, filtered and dried for later use.

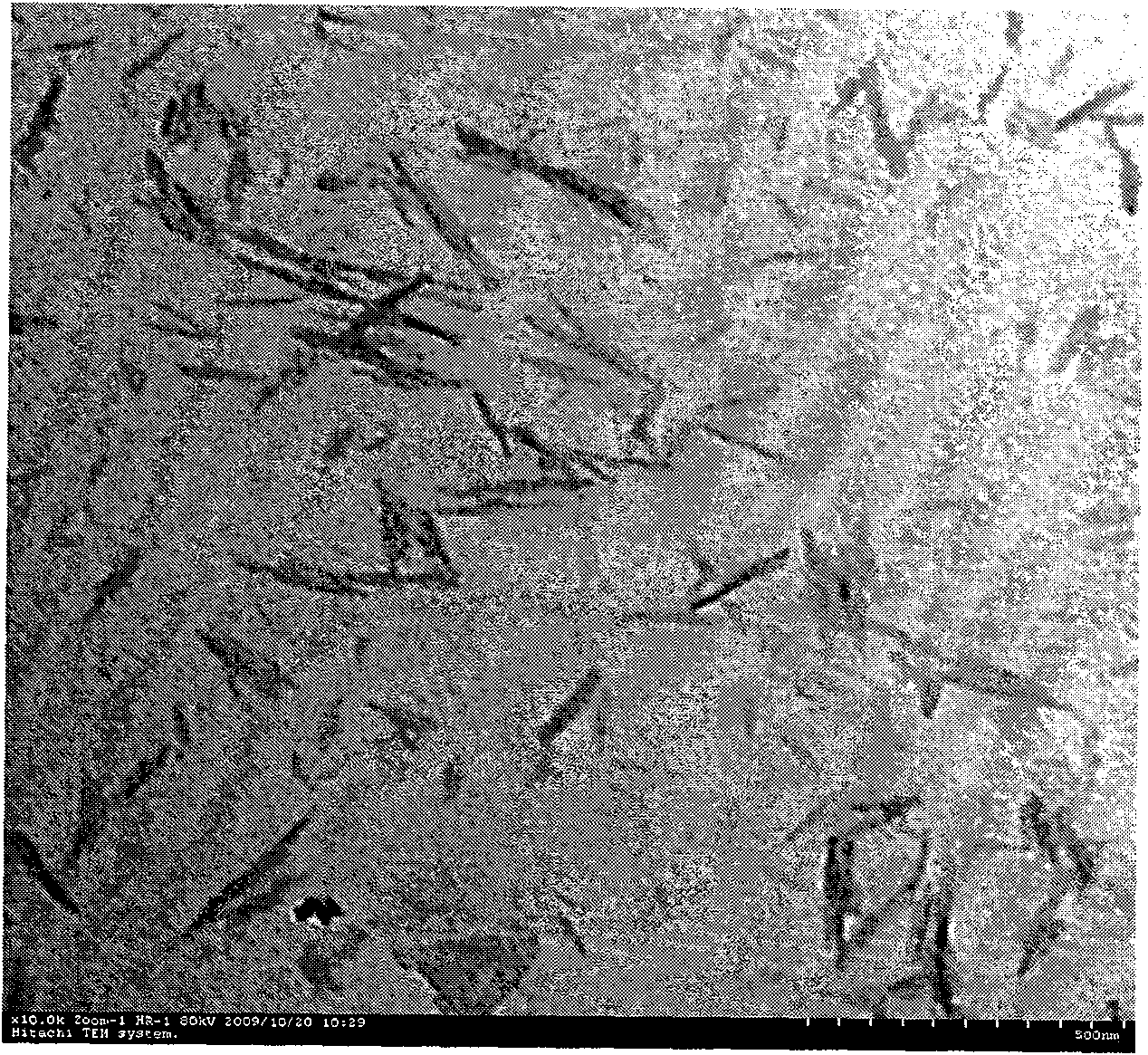

[0031] Immerse 0.5g of the above-mentioned cellulose powder accurately weighed in 25ml of sulfuric acid solution with a concentration of 64wt%, stir and react in a water bath at 60°C for 4h, then add 10 times the volume of deionized water to dilute the reaction solution; the diluted reaction solution Centrifuge at 8000 rpm; dialyze the suspension in deionized water for 24 hours until the pH is the same as that of the deionized water used. The molecular weight cut-off of the dialysis bag used is 8000-14000; finally, after ultrasonic dispersion with a power of 150w for 15 minutes, a stable nanocellulose whisker suspension is obtained, wherein the nanocellulose whiskers have a diameter of 20-30nm and a length of 100- 150nm. The morphology of the prepared nanocellulose whiskers is shown in the transmi...

Embodiment 3

[0035] (1) Preparation of nanocellulose suspension

[0036] Cotton cellulose powder was ultrasonically pretreated in an ice bath for 15 minutes, filtered and dried for later use.

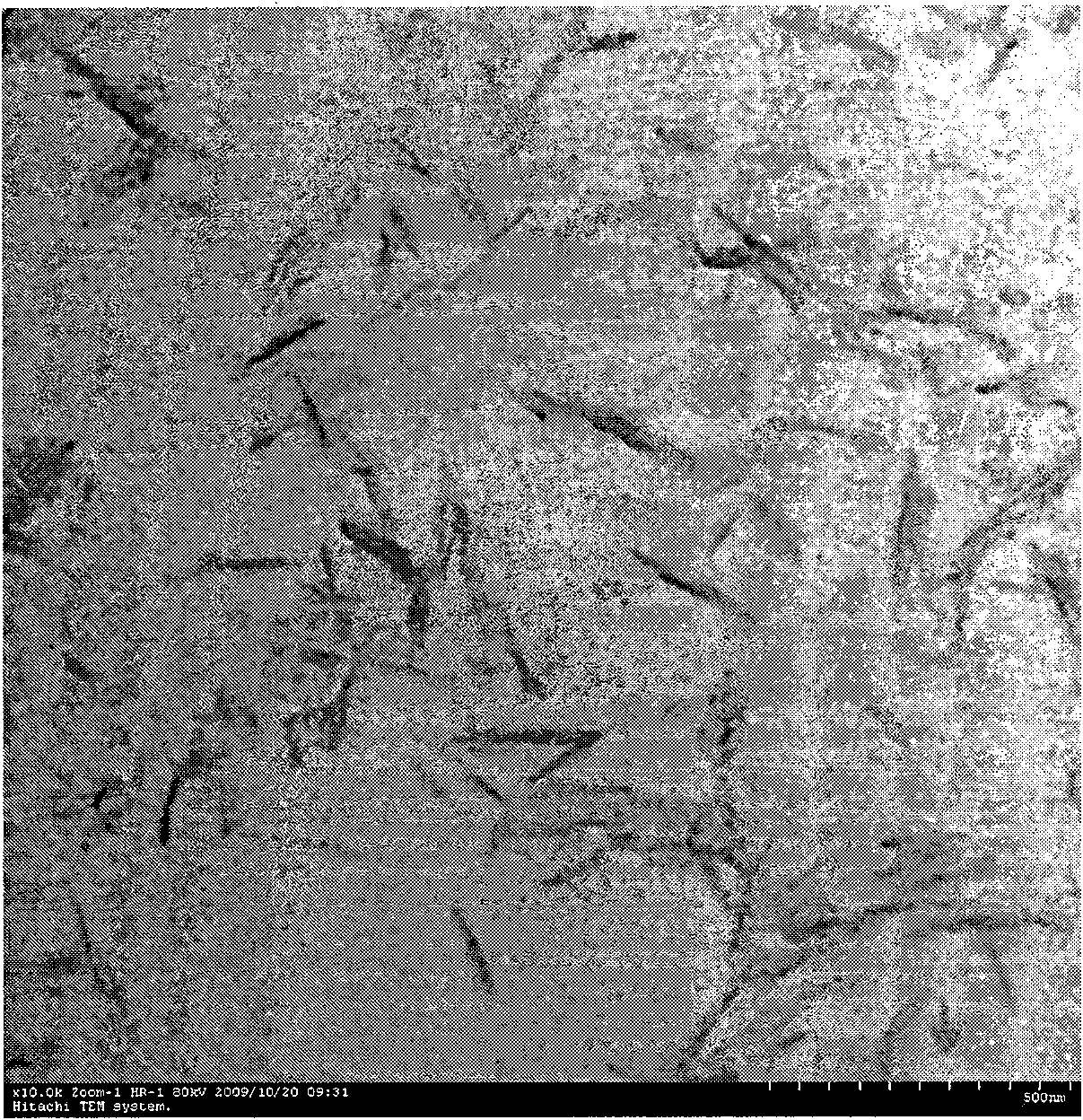

[0037] Immerse 0.5g of the above-mentioned cellulose powder accurately weighed in 16ml of sulfuric acid solution with a concentration of 64wt%, stir and react in a water bath at 75°C for 8h, then add 10 times the volume of deionized water to dilute the reaction solution; the diluted reaction solution Centrifuge at 8000 rpm; dialyze the suspension in deionized water for 24 hours until the pH is the same as that of the deionized water used. The molecular weight cut-off of the dialysis bag used is 8000-14000; finally, after 150w ultrasonic dispersion for 15min, a stable nanocellulose whisker suspension is obtained. Wherein, the nanocellulose whiskers have a diameter of 15-20nm and a length of 100-200nm. The morphology of the prepared nanocellulose whiskers is shown in the transmission electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com