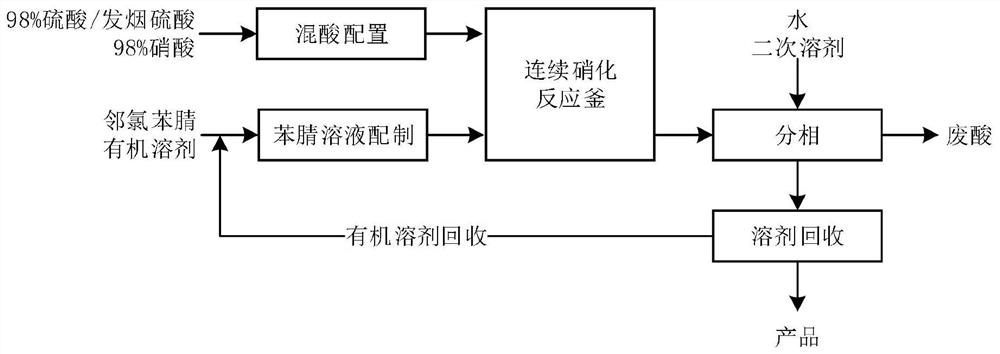

Novel process for synthesizing 2-cyano-4-nitrochlorobenzene through continuous nitration by solvent method

A technology of nitrochlorobenzene and solvent method, applied in the field of chemical production, can solve the problems of inability to realize continuous reaction, high safety risk level, affecting conversion rate, etc., to reduce reaction safety risk, facilitate reaction temperature control, and reduce waste water. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Get 500g of o-chlorobenzonitrile, dissolve it with 2000g of carbon tetrachloride, configure a benzonitrile solution with a mass content of 20%, configure a mixed acid nitrating agent with 98% sulfuric acid of 123g and 245.5g of 98% nitric acid, the sulfuric acid in the mixed acid nitrating agent The mass ratio of addition amount and nitric acid addition amount is 0.5:1, and benzonitrile solution and mixed acid nitrating agent are carried out nitration reaction in pipeline reactor, and the mass ratio of mixed acid nitrating agent and benzonitrile solution is 0.15:1, and reaction liquid reflux is 2 times that of the nitrating solution, the reaction temperature is controlled at 30°C, and the reaction residence time is 20min. Water and chlorobenzene are added to the nitrating solution, and the phases are separated after mixing evenly. The organic phase after the phase separation is evaporated to recover 99% tetrachloride Carbon, used again for dissolving o-chlorobenzonitrile...

Embodiment 2

[0053] Get 500g of o-chlorobenzonitrile, dissolve it with 750g of 2-methyltetrahydrofuran, configure a mass content of 40% benzonitrile solution, configure a mixed acid nitrating agent with oleum of 467.5g and 98% nitric acid of 234g, in the mixed acid nitrating agent The mass ratio of sulfuric acid addition and nitric acid addition is 2:1, and benzonitrile solution and mixed acid nitrating agent are carried out nitration reaction in microchannel reactor, and the mass ratio of mixed acid nitrating agent and benzonitrile solution is 0.56:1, and reaction liquid The reflux rate is 30 times that of the nitration solution, the reaction temperature is controlled at 0°C, and the reaction residence time is 20 minutes. Water and nitrobenzene are added to the nitration solution, and the phases are separated in a phase separator. The organic phase after phase separation is evaporated and recovered for 99 % of 2-methyltetrahydrofuran is used to dissolve o-chlorobenzonitrile again, and the ...

Embodiment 3

[0056] Get 500g of o-chlorobenzonitrile, dissolve it with 1000g of ethylene dichloride, configure a benzonitrile solution with a mass content of 33%, configure a mixed acid nitrating agent with 386g of oleum and 257g of 98% nitric acid, add sulfuric acid to the mixed acid nitrating agent The mass ratio of amount and nitric acid addition amount is 1.5:1, and benzonitrile solution and mixed acid nitrating agent are carried out nitration reaction in microchannel reactor, and the mass ratio of mixed acid nitrating agent and benzonitrile solution is 0.43:1, and reaction solution reflux It is 14 times that of the nitration solution, the reaction temperature is controlled at 10°C, and the reaction residence time is 20 minutes. Water and o-dichlorobenzene are added to the nitration solution, and the phases are separated in a phase separator. The organic phase after phase separation is evaporated and recovered 99% Dichloroethane is used to dissolve o-chlorobenzonitrile again, and the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com