Fluorine-silicon modified epoxy resin power paint

A technology of epoxy resin powder and fluorosilicone modification, which is applied in powder coatings, coatings, etc., can solve the problems of high temperature resistance and insufficient pollution resistance, achieve bright appearance, improve high temperature resistance, and isolate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

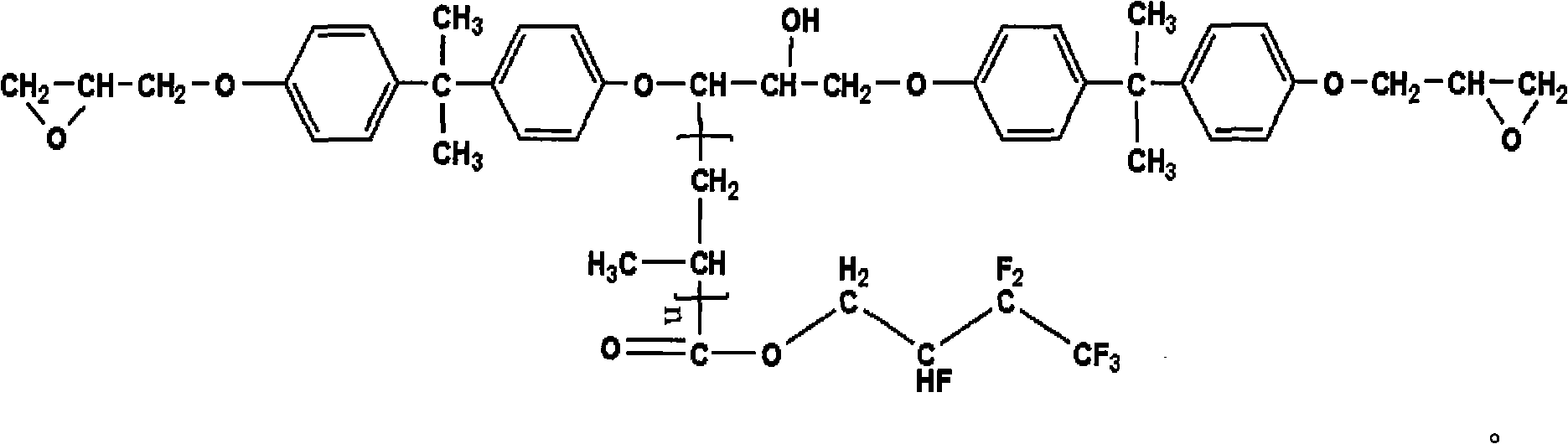

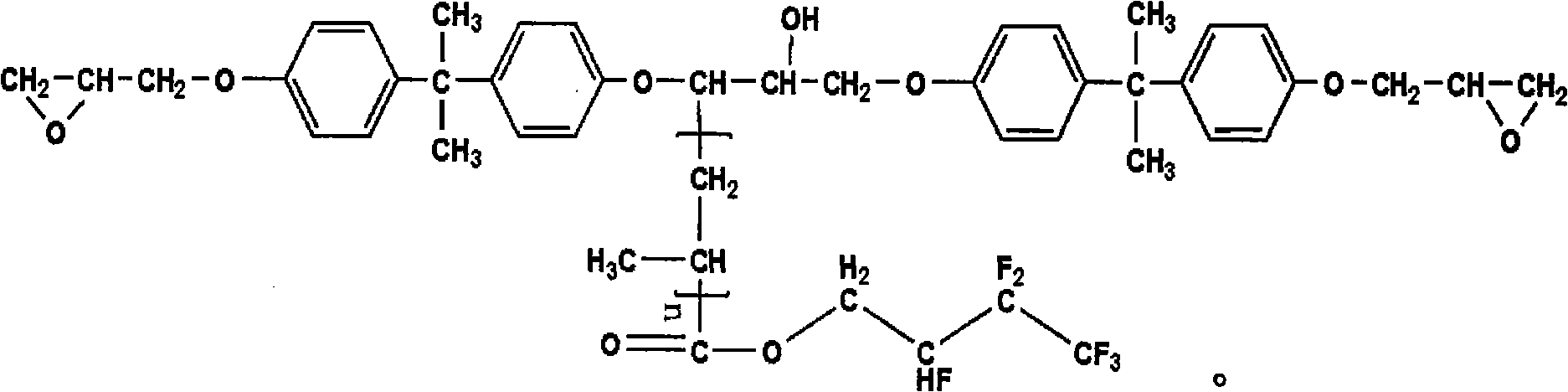

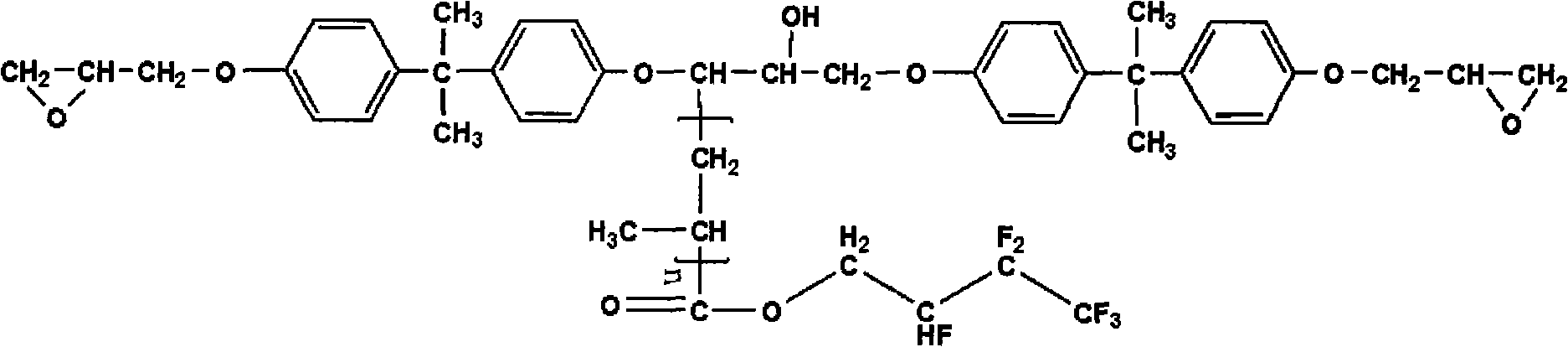

Method used

Image

Examples

preparation example Construction

[0034] The coating made of the fluorine-silicon modified epoxy resin powder coating obtained according to the above preparation method was tested and measured for various performance indicators, including: coating appearance measurement, coating thickness measurement, impact strength test, positive and recoil Test, Pencil Hardness Test, Bending Hardness Test, Adhesion Test, Salt Spray Resistance Test, Cupping Test, Determination of Heat Resistance of Paints and Varnishes with Reference to GB / T1735-2009, Determination of Contact Angle, Acid Resistance Test and Alkali Resistance sex test.

[0035] In the above test and determination, the contact angle measurement adopts German Data physics OCA20 video optical contact angle measuring instrument, the test method is: the contact medium adopts deionized water, the droplet volume is 3 μ L, the droplet is mixed with the fluorosilicon modified epoxy of the present invention The coating made of resin powder coating was measured after 30...

Embodiment 1

[0037] Component Component content (weight%)

[0038] Fluorine modified acrylic epoxy resin 20

[0039] Silicone resin 40

[0040] Nano gas silica 0.5

[0041] Anti-Yellowing Benzoin 1

[0042] Polyacrylate leveling agent 1

[0043] Silica 15

[0044] Mica powder 20

[0045] Flow enhancer 0.2

[0046] Zinc iron yellow pigment 1.8

[0047] After the above-mentioned components are mixed uniformly, the screw extruder is mixed and melted at 90°C, extruded, tableted, crushed, and sieved through a 160-mesh screen to obtain a light yellow fluorosilicone modified epoxy resin powder coating.

[0048] The coatings made of the above-mentioned fluorine-silicon modified epoxy resin powder coatings were tested and determined for various performance indicators, and the results are as follows:

[0049] Appearance of coating: smooth, no shrinkage cavity, no pinhole;

[0050] Coating thickness: 40-60um;

[0051] Impact strength: 50kg·cm;

[0052] Positive recoil test: pass;

[0053] P...

Embodiment 2

[0063] Component Component content (weight%)

[0064] Fluorine modified acrylic epoxy resin 40

[0065] Silicone resin 20

[0066] Nano gas silica 0.6

[0067] Anti-Yellowing Benzoin 1.5

[0068] Polyacrylate leveling agent 2

[0069] Silica 20

[0070] Wollastonite 12

[0071] Flow enhancer 0.9

[0072] Zinc iron yellow pigment 2

[0073] After the above-mentioned components are mixed evenly, the screw extruder is mixed and melted at 100°C, extruded, pressed into tablets, crushed, and sieved through a 160-mesh sieve to obtain a light yellow fluorosilicone modified epoxy resin powder coating.

[0074] The coatings made of the above-mentioned fluorine-silicon modified epoxy resin powder coatings were tested and determined for various performance indicators, and the results are as follows:

[0075] Appearance of coating: smooth, no shrinkage cavity, no pinhole;

[0076] Coating thickness: 40-60um;

[0077] Impact strength: 50kg·cm;

[0078] Positive recoil test: pass;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com