Method for preprocessing coal tar

A coal tar and pretreatment technology, which is applied in the field of removing impurities from coal tar, can solve the problems of unsuitable coal tar pretreatment, low degree of automation, and high labor intensity, so as to achieve good economic benefits for enterprises, improve processing capacity, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

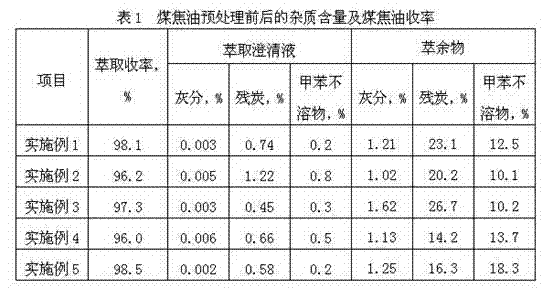

[0023] Mix 2000g of full cut medium and low temperature coal tar with 2000g of catalytic diesel oil (mass ratio 1:1), heat the resulting mixture to 60°C, pre-separate it with a hydrocyclone, and then centrifuge it with a horizontal screw sedimentation centrifuge Separation, 3623g of catalytic diesel soluble matter and 377g of extraction insoluble matter were separated. Mix the extracted insolubles with 1508g of benzene (mass ratio 1:4), heat the resulting mixture to 60°C, and perform centrifugation on a horizontal spiral sedimentation centrifuge to separate 1844g of benzene solubles and 39g of benzene insolubles (ie raffinate). Catalyzed diesel solubles and benzene recovery solubles are uniformly mixed as feed components for coal tar hydrotreating. The impurity content and extraction yield of coal tar after pretreatment are shown in Table 1.

Embodiment 2

[0025] Mix 1000g coal tar heavy oil (>350℃ fraction) with 4000g coal tar hydrogenation unit’s hydrogenated oil >160℃ distillate (mass ratio 1:4), heat the mixture to 150℃, and enter it in a tangential way The continuous settling tank is used for pre-separation, and then the horizontal spiral sedimentation centrifuge is used for centrifugation to separate 4574g of distillate soluble matter and 426g of extracted insoluble matter. The extracted insolubles were mixed with 426g of toluene (mass ratio 1:1), and the resulting mixture was heated to 100°C, and centrifuged in a horizontal spiral sedimentation centrifuge to separate 814g of toluene solubles and 38g of raffinate. The distillate soluble matter and the recovered toluene soluble matter were uniformly mixed and used as the feedstock component for coal tar hydrotreating. The impurity content and extraction yield of coal tar after pretreatment are shown in Table 1.

Embodiment 3

[0027] Mix 1000g of coal tar gasoline and diesel fraction (<350°C fraction) after extracting phenol and naphthalene with 3000g of kerosene (mass ratio 1:3), heat the resulting mixture to 120°C, and enter the continuous settling tank in a tangential way for pre-separation. Carry out centrifugation with a horizontal spiral sedimentation centrifuge again, isolate kerosene soluble matter 3845g and extract insoluble matter 155g. Mix the extracted insolubles with 310g of xylene (mass ratio 1:2), heat the resulting mixture to 150°C, and conduct centrifugation in a horizontal spiral sedimentation centrifuge to separate 438g of xylene solubles and 27g of raffinate . The kerosene soluble matter and the soluble matter recovered from xylene were uniformly mixed and used as the feedstock component for coal tar hydro-upgrading. The impurity content and extraction yield of coal tar after pretreatment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com