Online ramie biological degumming method

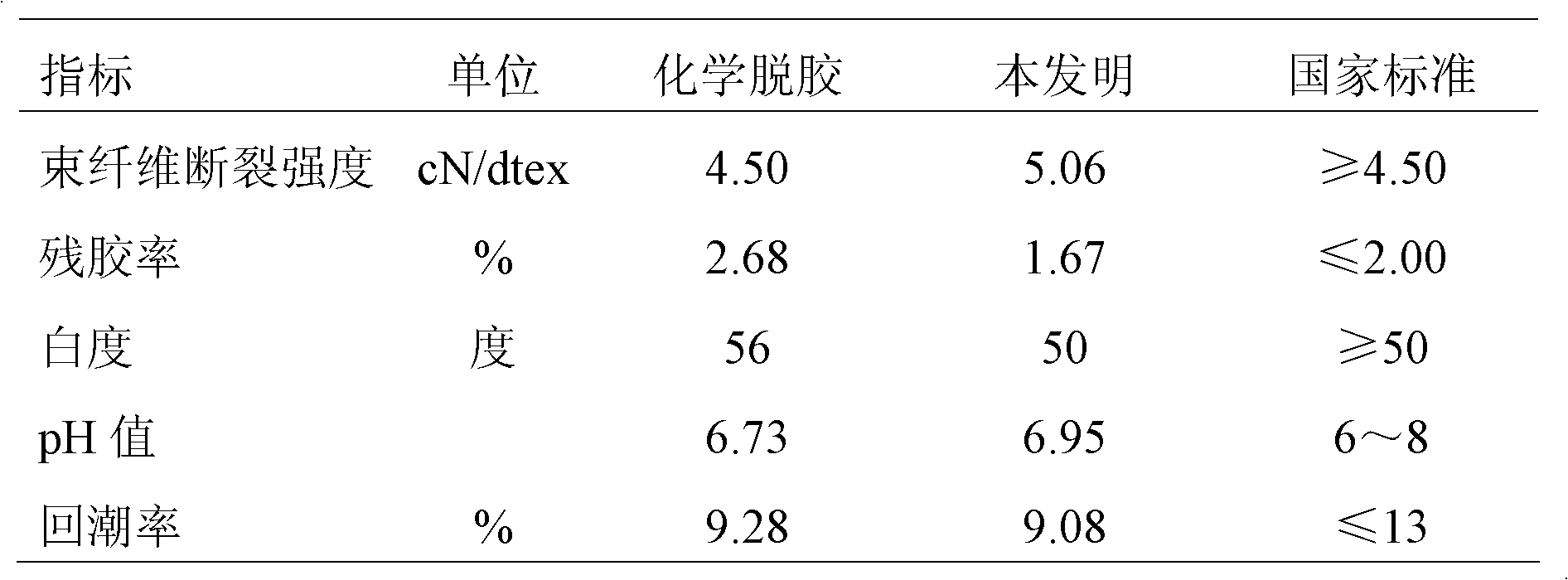

A technology of biological degumming and ramie, applied in the direction of bacterial retting, can solve the problems of high residual glue rate, low breaking strength, low production rate, etc., and achieve the effect of uniform degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, including pretreatment step and fermentation step;

[0027] Pretreatment step: with 500kg of dried ramie raw hemp, at a temperature of 0°C, use 5 × 10 4 The pressure of Pa is rubbed, and then the raw hemp after rubbing is put into the pretreatment tank, and kept at a temperature of 80°C for 150s to obtain pretreated hemp;

[0028] Fermentation steps: Take the pretreated hemp out of the pretreatment tank, put it into the fermenter, inject 4.5t of water, the mass ratio of water to pretreated hemp is 9:1; adjust the temperature of the fermenter to 25°C, add 45kg of bacteria liquid, constitute the fermentation liquid, and the concentration of the bacterial liquid is 2×10 10 cfu / mL, the mass ratio of bacterial liquid to water in the fermenter is 0.01:1; adjust the initial pH value of the fermented liquid to 5.0, feed air into the fermented pot for fermentation, and control the dissolved oxygen in the fermented liquid during the fermentation process to 5%, the...

Embodiment 2

[0031] Embodiment 2, including pretreatment step and fermentation step;

[0032] Pretreatment step: 500kg of dried ramie raw hemp, at a temperature of 35°C, use 1 × 10 5 The pressure of Pa is rubbed, and then the raw hemp after rubbing is put into a pretreatment tank, and kept at a temperature of 100°C for 80s to obtain pretreated hemp;

[0033] Fermentation steps: Take the pretreated hemp out of the pretreatment tank, put it into the fermenter, inject 6t of water, the mass ratio of water to pretreated hemp is 12:1; adjust the temperature of the fermenter to 32°C, add 480kg of bacterial liquid , constitute the fermentation liquid, the concentration of the bacterial liquid is 1×10 8 cfu / mL, the mass ratio of bacterial liquid to water in the fermenter is 0.08:1; adjust the initial pH value of the fermented liquid to 6.5, feed air into the fermented pot for fermentation, and control the dissolved oxygen in the fermented liquid during the fermentation process to 22%, the bacteri...

Embodiment 3

[0036] Embodiment 3, including pretreatment step and fermentation step;

[0037] Pretreatment step: with 500kg of dried ramie raw hemp, at a temperature of 70°C, use 2×10 5 The pressure of Pa is rubbed, and then the raw hemp after rubbing is put into a pretreatment tank, and kept at a temperature of 130°C for 5s to obtain pretreated hemp;

[0038] Fermentation steps: Take the pretreated hemp out of the pretreatment tank, put it into the fermentation tank, inject 7.5t of water, the mass ratio of water to pretreated hemp is 15:1; adjust the temperature of the fermentation tank to 38°C, add 1.125t of Bacterial liquid, constitutes the fermentation liquid, the concentration of the bacterial liquid is 5×10 5 cfu / mL, the mass ratio of bacterial liquid to water in the fermenter is 0.15:1; adjust the initial pH value of the fermented liquid to 8.0, feed air into the fermented pot for fermentation, and control the dissolved oxygen in the fermented liquid during the fermentation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com