Device and method for mounting optical glass under vision guide

A technology of optical glass and installation method, which is applied in nuclear reactors, nuclear power generation, climate sustainability, etc., can solve problems such as inability to guarantee installation accuracy, easy pollution of optical glass, damage to optical components, etc., to improve reliability and safety, The effect of avoiding accidental injury and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

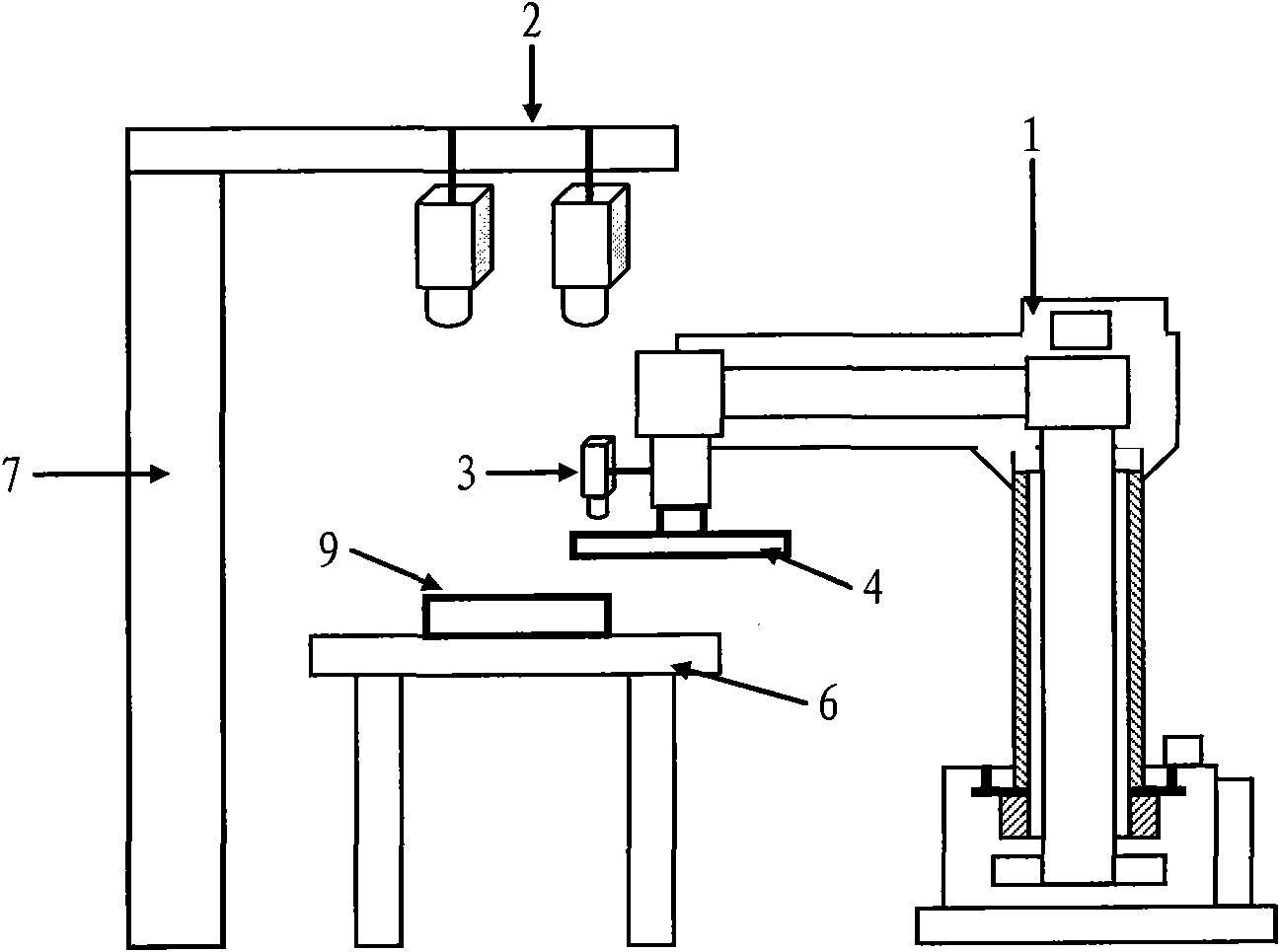

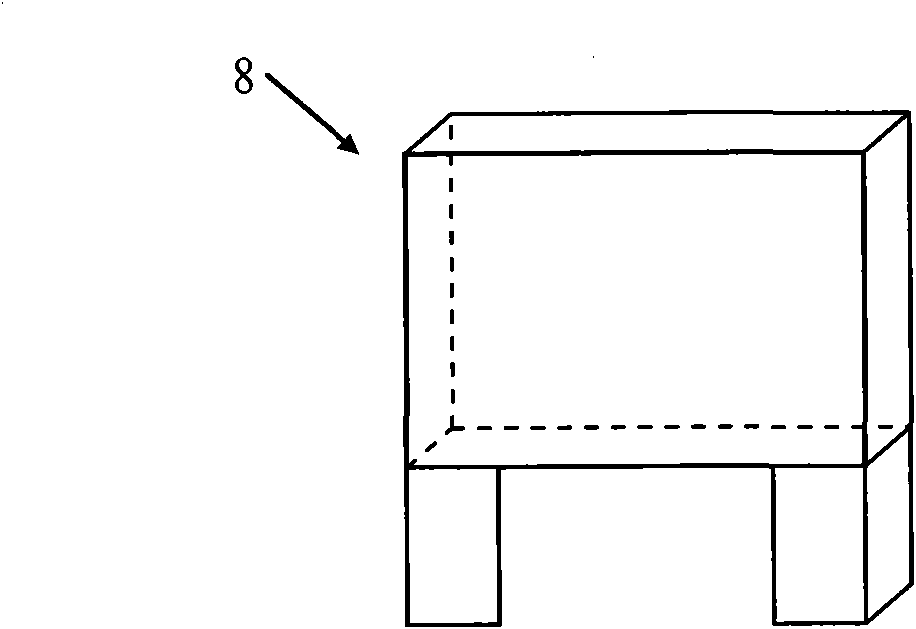

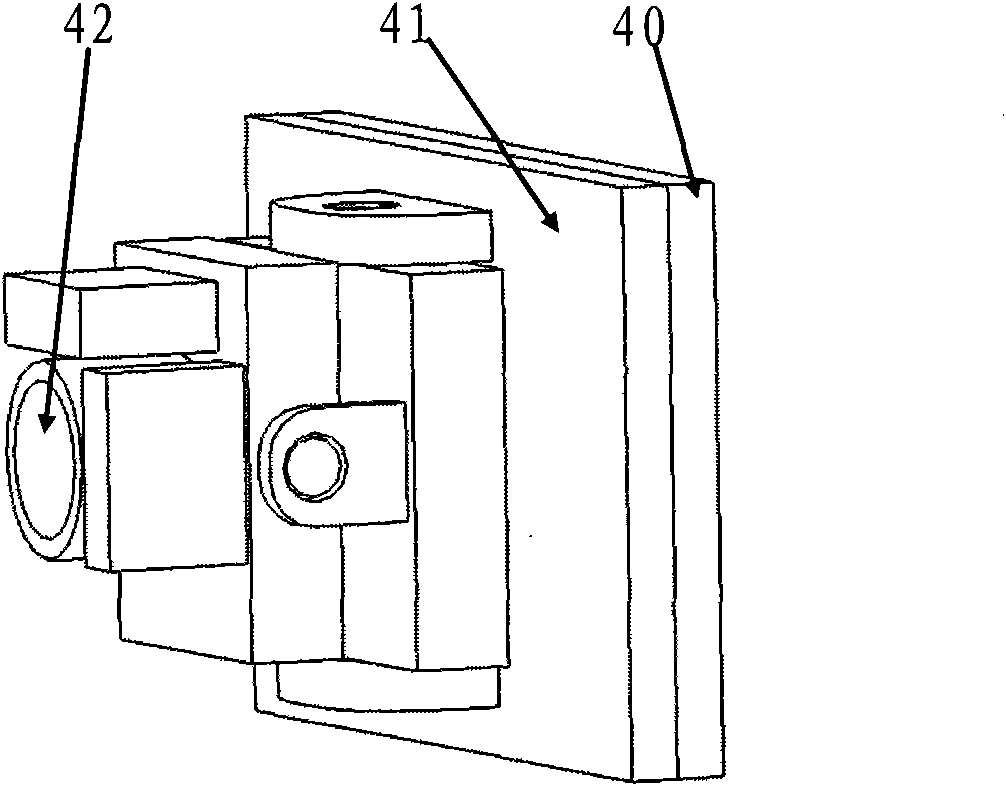

[0044] Such as figure 1 It shows a large-scale optical glass installation device based on an industrial robot under visual guidance, including an industrial robot 1, an upper visual recognition unit 2, a front-end visual positioning unit 3, a grabbing device 4, a control cabinet 5, a workbench 6, a bracket 7, and a glass frame 8 , Optical glass 9. The upper visual recognition unit 2 is installed on the horizontal end of the support 7 and is located above the workbench 6. The horizontal end of the support 7 is parallel to the work surface of the workbench 6, and is used to collect images of the optical glass 9 on the workbench 6 and identify the optical glass 9. The rough position of the apex of the glass 9; the front-end visual positioning unit 3 is installed on the arm of the industrial robot 1 and is positioned above the workbench 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com