Treating method for efficiently catalyzing and oxidizing chlor-alkali industrial waste water

A technology of catalytic oxidation and chlor-alkali industry, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as environmental and human life hazards, waste of water resources, etc., and achieve low operating costs and high technology Simple, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

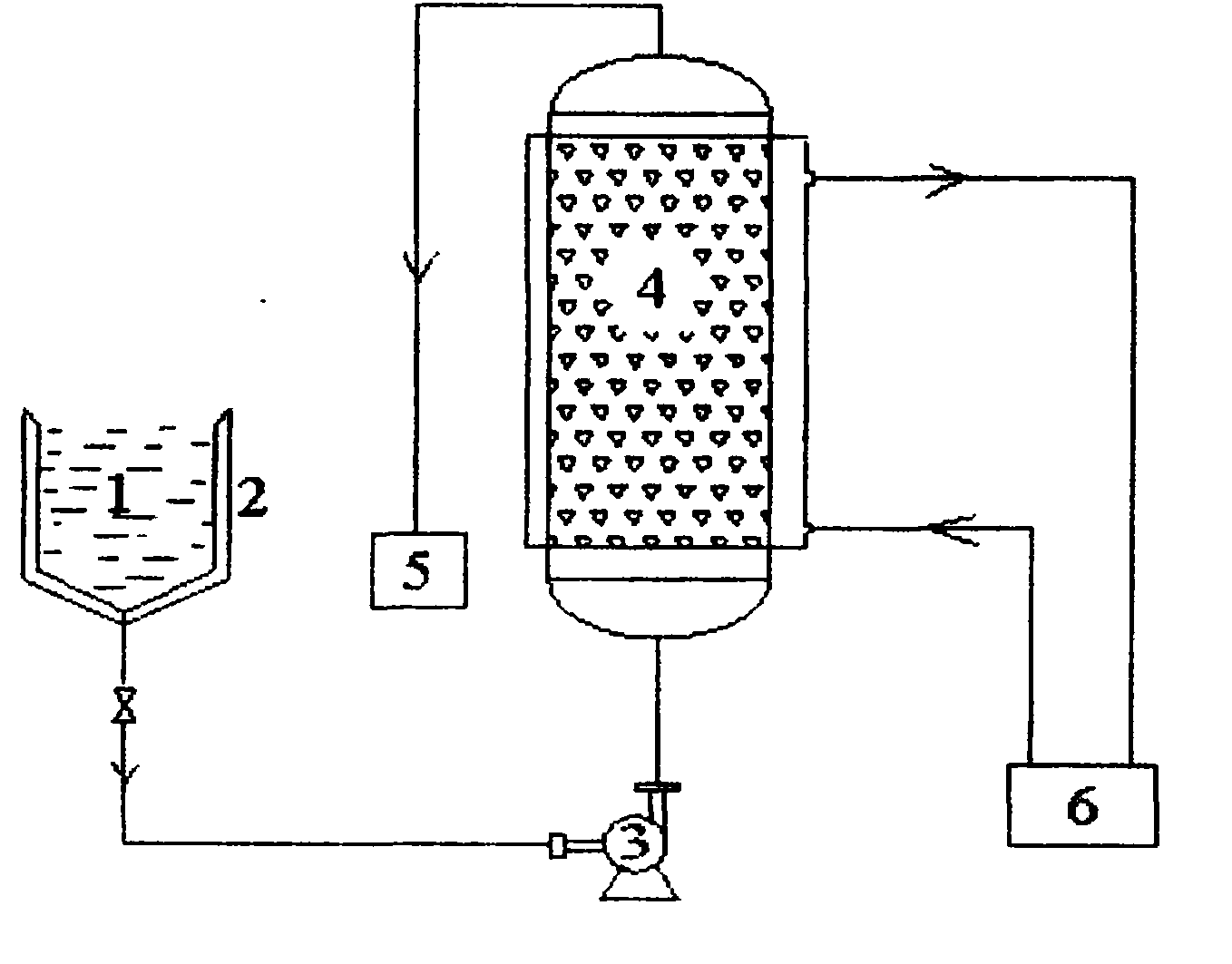

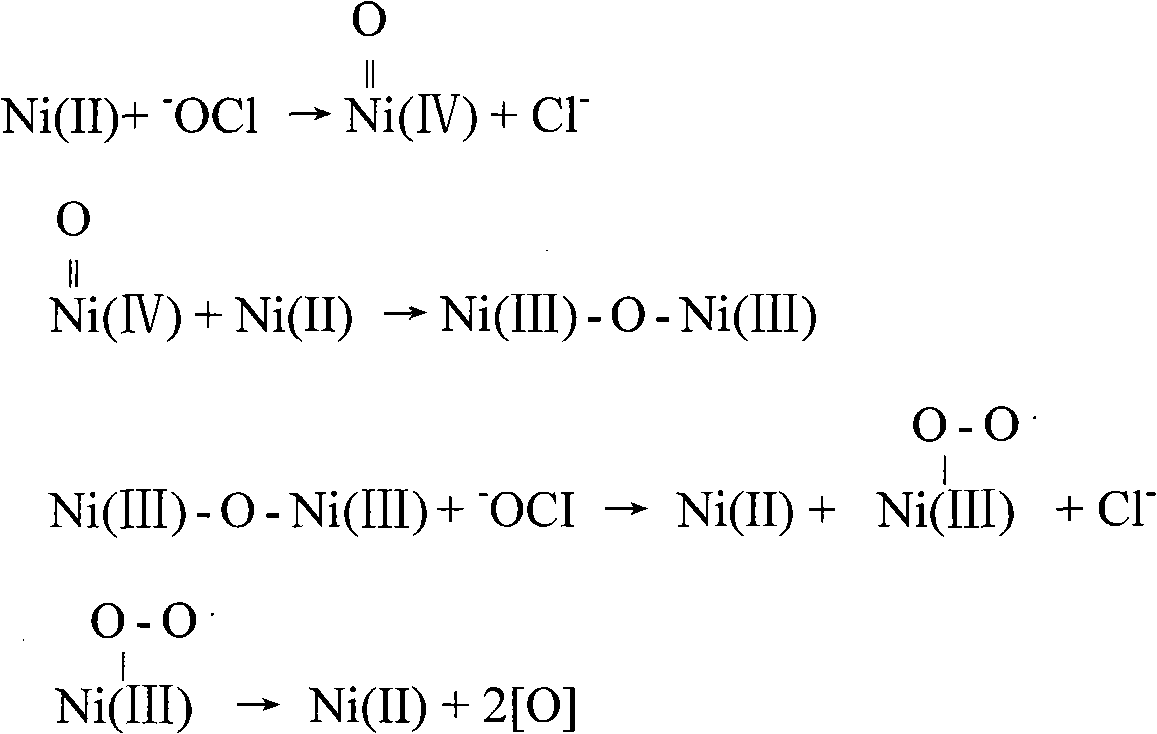

[0023] Example 1: Catalytic oxidation treatment of chlor-alkali wastewater containing sodium hypochlorite by Al2O3 supported nickel oxide catalyst

[0024] The reaction is carried out in a reactor made of glass. Put the chlor-alkali wastewater containing sodium hypochlorite in the liquid storage tank, and use the peristaltic pump to adjust the space velocity, so that the alkaline wastewater containing sodium hypochlorite has a space velocity of 1.6h from bottom to top -1 Continuously passing through the catalytic oxidation reaction bed equipped with 120g catalyst, the catalyst catalytically decomposes the sodium hypochlorite solution, and the results are shown in Table 1.

[0025] The space velocity of embodiment 2-6 is shown in Table 1, and other conditions and methods are with embodiment 1, and the results are shown in Table 1:

[0026] Table 1 Catalytic oxidation degradation effect of chlor-alkali wastewater containing sodium hypochlorite

[0027]

[0028] As ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com