Clostridium acetobutylicum and construction method and purposes thereof

A clostridium acetobutylicum, construction method technology, applied in microorganism-based methods, biochemical equipment and methods, bacteria and other directions, can solve the problems of screening efficiency, quantity restricting industrial application, etc., and achieves wide applicability, short cycle, fast growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Construction of Clostridium acetobutylicum p1147 (CGMCC No3686)

[0044] a. Protoplast preparation: select isolated and cultivated ATCC824 bacteria, use lysozyme with a final concentration of 4 mg / ml to digest for 30 minutes, and heat the ATCC824 bacteria protoplasts to death at 55°C for 30 minutes.

[0045] b. Regeneration and Fusion:

[0046] Add the lethal protoplasts to 5ml PEG4000, induce fusion of the protoplasts for 5 minutes, collect by centrifugation for 10min, and add Ca at a final concentration of 60mM 2+ , and 75mMMg 2+ solution, mix the bacteria evenly, evenly spread on the SRA solid plate, and incubate at 37°C for 3 days in an anaerobic box to observe the results.

[0047] in:

[0048]ATCC824 was purchased from the market from the American Strain Collection.

[0049] Corn flour medium: Each liter of medium contains 50g of corn flour.

[0050] RCM medium: Each liter medium contains 3.0g of yeast powder, 10.0g of peptone, 10.0g of beef extract, 5.0g of ...

Embodiment 2

[0058] Construction of Clostridium acetobutylicum p1147 (CGMCC No3686)

[0059] a. Protoplast preparation:

[0060] Collect ATCC824 bacteria, use lysozyme with a final concentration of 10 mg / ml to digest for 40 minutes, and heat the protoplasts to death at 60°C for 40 minutes.

[0061] b. Add the lethal protoplasts to 10ml PEG6000, induce fusion of the protoplasts for 10min, collect by centrifugation for 10min, and add Ca with a final concentration of 50mM 2+ , and 75mMMg 2+ solution, mix the bacteria evenly, evenly spread on the SRA solid plate, in an anaerobic box, incubate at 37°C for 2 days and observe the results.

[0062] in:

[0063] ATCC824 was purchased from the market from the American Strain Collection.

[0064] Corn flour medium: Each liter of medium contains 50g of corn flour.

[0065] RCM medium: Each liter medium contains 3.0g of yeast powder, 10.0g of peptone, 10.0g of beef extract, 5.0g of glucose, 10.0g of starch, 3.0g of sodium acetate, 0.5g of L-cystei...

Embodiment 3

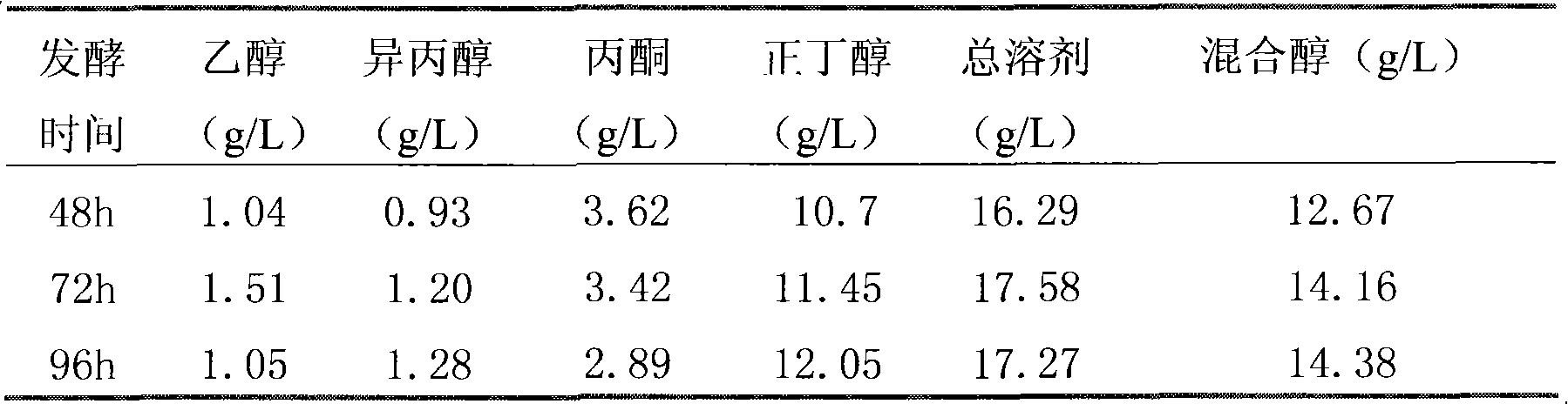

[0070] Experimental comparison of Clostridium acetobutylicum p1147 constructed and cultured in Example 1 with commercially available ATCC824 for the production of mixed alcohols.

[0071] 1. Clostridium acetobutylicum p1147 cultured in Example 1 (for experimental group 1) and commercially available ATCC824 (for control group) were fermented with 6% corn fermented glutinous rice medium at a temperature of 37° C. for 48-96 hours.

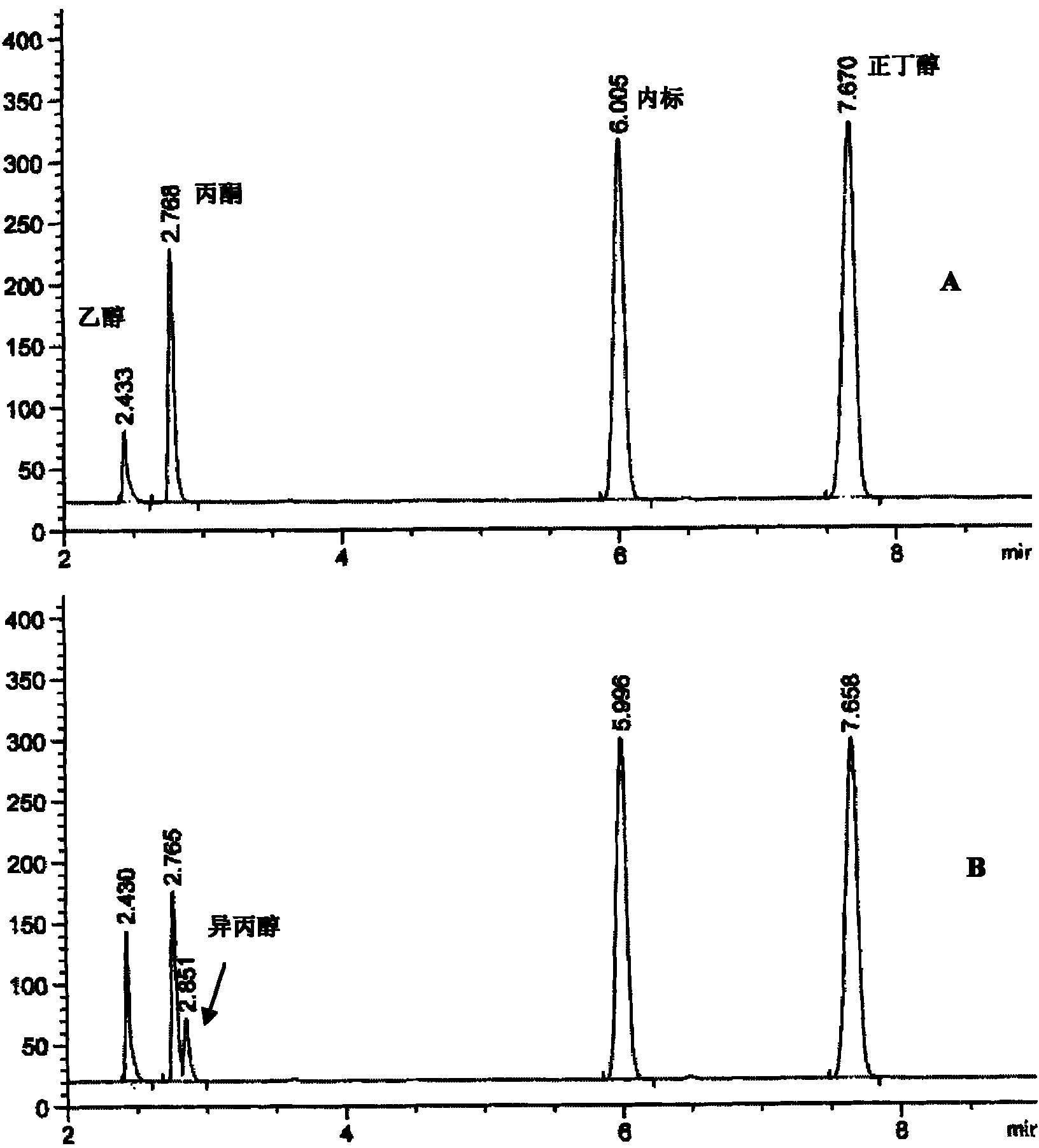

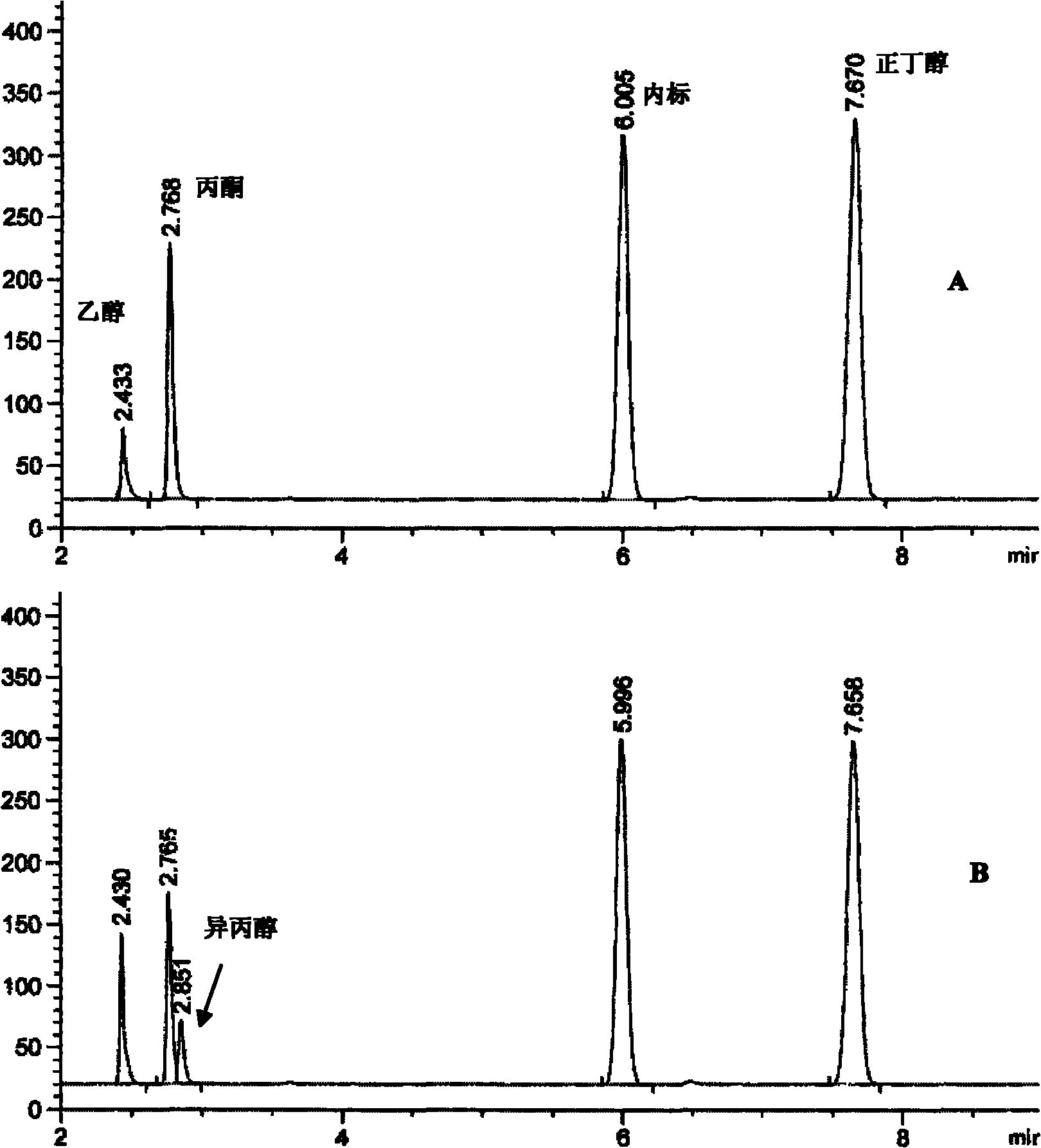

[0072] 2. Detection of fermentation products

[0073] Take the fermentation broth and use GC-7890A (Agilengt Technologies) to detect the changes of fermentation components, detection conditions: chromatographic column DB-624 (30m×0.32mm×1.8μm, Agilengt Technologies); detector: FID (300°C); carrier gas: N 2 ;Temperature mode: 1-stage temperature program, initial temperature 55°C, keep 8min, rate 45°C / min, final temperature 190°C, keep 9min; split ratio: 30:1; sampling method: autosampler (Agilengt Technologies), Injection volume: 0.2 μL; quantitative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com