Preparation method of polyurethane nanofiber immobilized enzyme

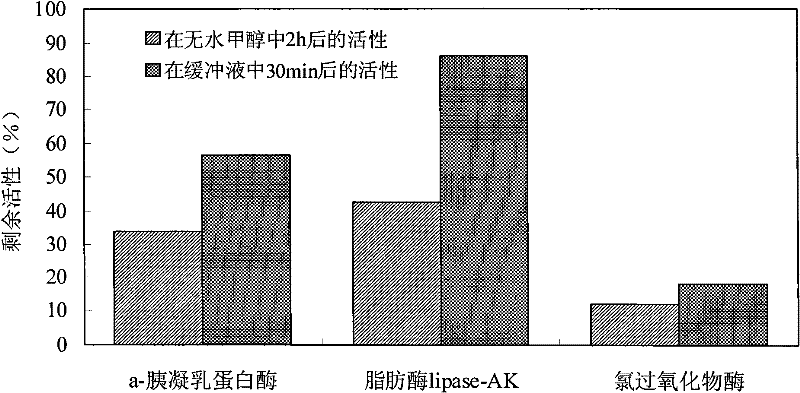

A nanofiber, immobilized enzyme technology, applied in the direction of being immobilized on/in an organic carrier, can solve the problems of reduced enzyme activity, no activity recovery performance, etc., to achieve high enzyme loading, easy recovery and repetition Use, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described below in specific forms, but the present invention is not limited to the embodiments.

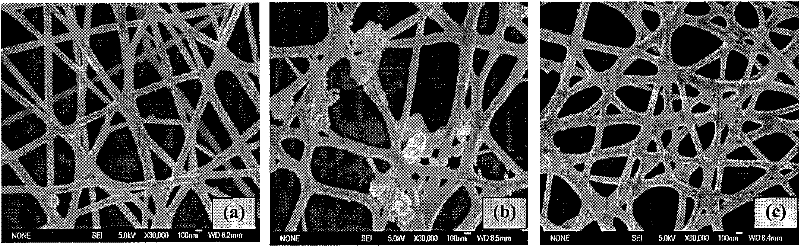

[0021] 1) The preparation method of polyurethane nanofiber membrane: dissolving polyurethane in an organic solvent to prepare a solution of 10-20% by weight, adding 1-5% LiCl relative to the weight of polyurethane, fully dissolving, injecting into electrospinning In the silk device, electrospinning is carried out under the conditions of a voltage of 20-30 kV, a flow rate of the spinneret solution of 0.1-0.5 ml / hour, and a receiving distance of 10-20 cm to obtain polyurethane nanometer fibers with a fiber diameter of 100-500 nm. Fiber membrane: Dry the nanofiber membrane in an oven at 60° C. for 24 hours, and then wash it with deionized water for use.

[0022] 2) Use physical adsorption to adsorb the inactive protein on the surface of the polyurethane nanofiber membrane to modify it. The specific method is to put the polyurethane nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com