Method for preparing diglyceride from phosphatidase A1 through catalytic esterification

A technology of diglyceride and catalyzed esterification, applied in the direction of fermentation, etc., to achieve the effect of cost advantage and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation of reaction raw material fatty acid: Weigh 500.00g soybean oil in a 1000mL three-necked flask and react for 8h in a constant temperature water bath at 40℃ with a stirring speed of 300r / min to obtain a hydrolysate; the hydrolysate is allowed to stand for 30min to separate into two layers ; The upper layer is an oil layer containing glycerides and fatty acids. The oil layer is at 160°C and a pressure of 1.0 Pa to obtain hydrolyzed fatty acids (FFA) through molecular distillation.

[0023] The acid value of oil is determined according to GB / T 5530-1995 titration method.

[0024] The calculation method of the esterification rate is as follows: esterification rate=(initial fatty acid acid value-oil layer acid value after reaction) / initial fatty acid acid value×100%. HPLC method was used to determine the content of crude diglyceride and molecularly distilled diglyceride.

Embodiment 1

[0026] Put the fatty acid and glycerol molar ratio 0.5:1 in the sandwich beaker to obtain the substrate; add 80 U / g substrate phospholipase A1 (Lecitase Ultra) and the substrate mass 4.0wt% deionized water to the substrate in turn , The reaction temperature is controlled to 40℃ by super constant temperature water bath, and the magnetic stirrer is used to stir (rotation speed 300r / min). The reaction is carried out under vacuum (absolute pressure 400Pa), and the reaction time is 12h; after the enzymatic hydrolysis reaction is completed, the reaction solution is Centrifuge at 3000r / min for 10 minutes to separate layers, the lower layer is unreacted glycerin, and the upper layer is crude diglyceride (containing fatty acid impurities); the acid value of the upper layer is measured, the esterification rate is 43.87%, and the DAG content in the crude diglyceride is 12.78%.

[0027] The crude diglyceride layer obtained above is fed into a molecular distillation feed tank, and after dehyd...

Embodiment 2

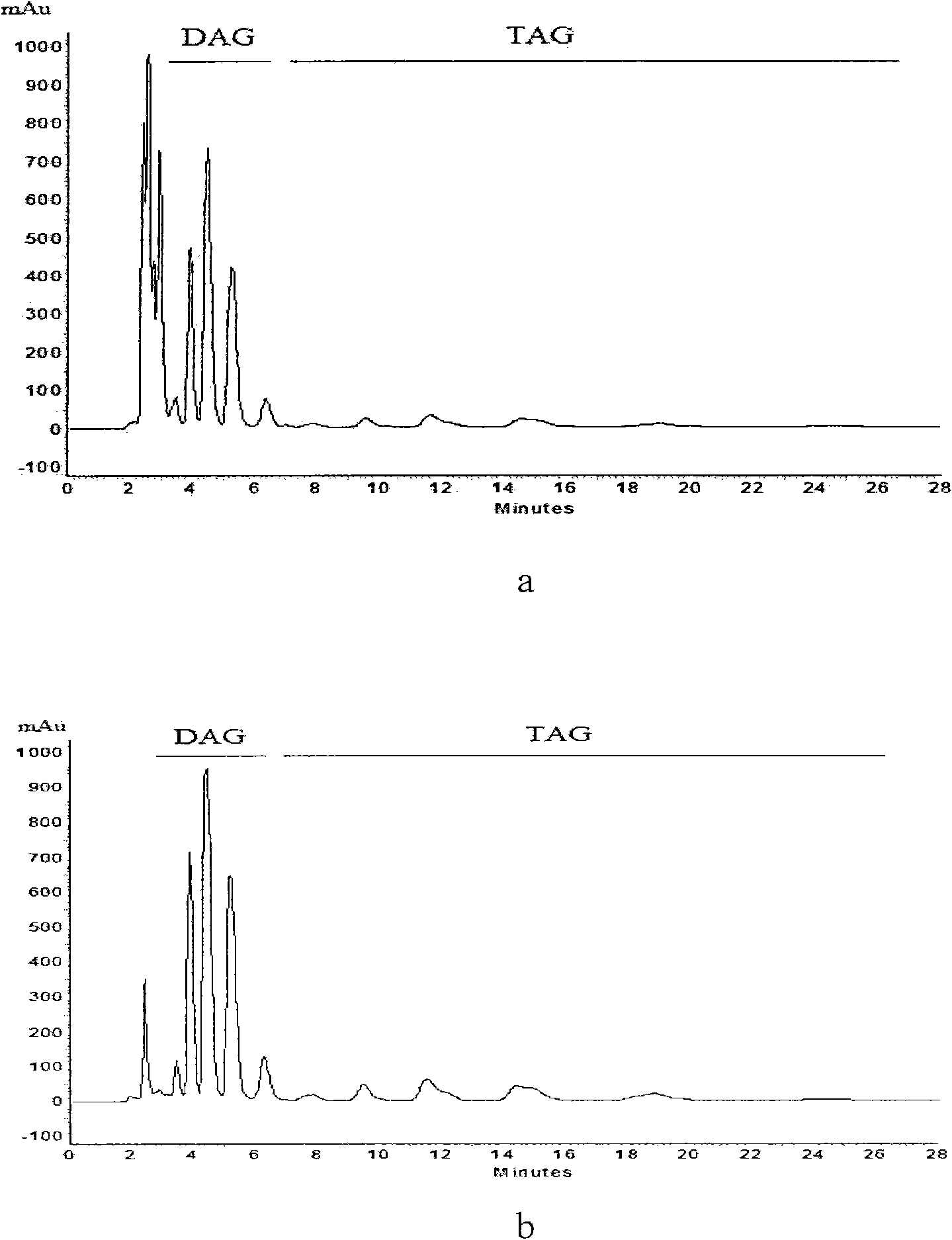

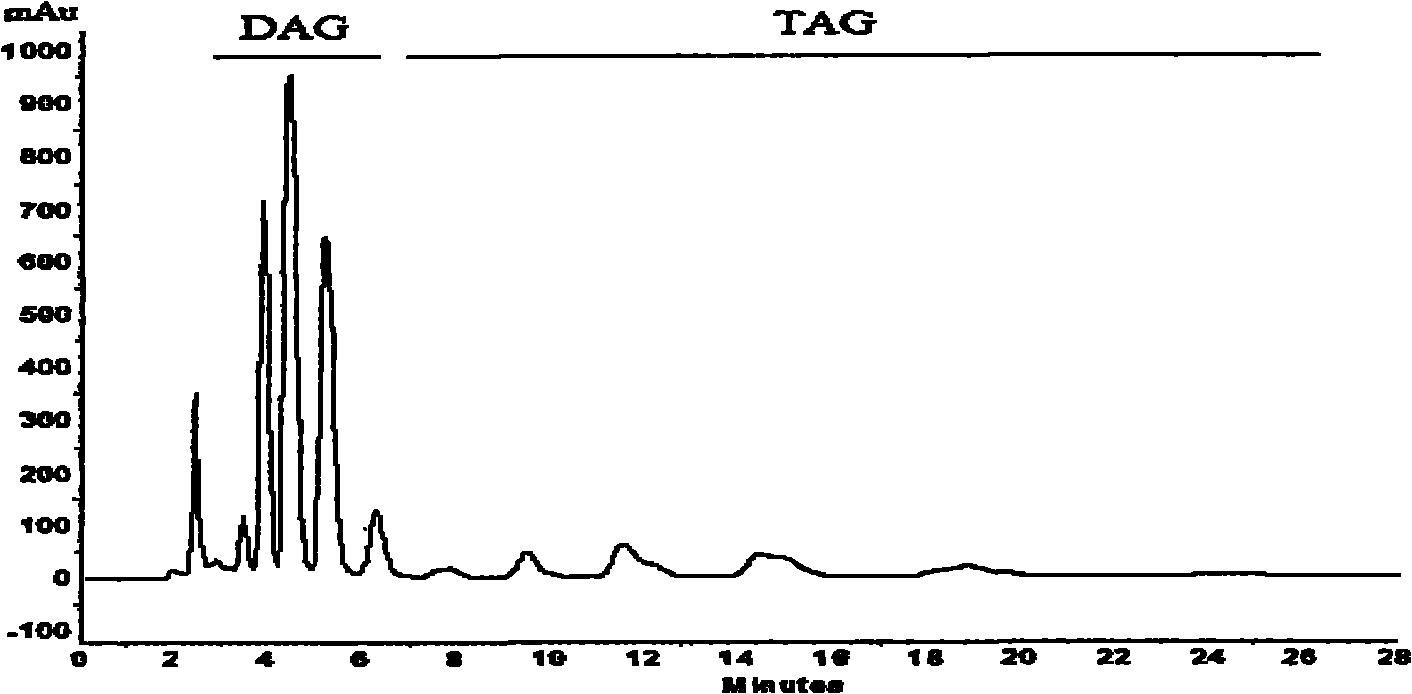

[0029] Place the fatty acid and glycerol at a molar ratio of 2.21:1 in a sandwich beaker to obtain a substrate; add 90 U / g substrate phospholipase A1 (Lecitase Ultra) and a substrate mass of 4.0 wt% deionized water to the substrate in turn , The reaction temperature is controlled to 41 ℃ by super constant temperature water bath, and the magnetic stirrer is used to stir (rotation speed 300r / min). The reaction is carried out under vacuum (absolute pressure 2000Pa), and the reaction time is 12h; after the enzymatic hydrolysis reaction is completed, the reaction solution is Centrifuge at 3000r / min for 10 minutes to separate layers. The lower layer is unreacted glycerin, and the upper layer is crude diglyceride (containing fatty acid impurities); the acid value of the upper layer is measured, the esterification rate is 82.34%, and the DAG content in the crude diglyceride is 41.54%, the HPLC analysis chart is as figure 1 (a) Shown.

[0030] The crude diglyceride layer obtained above i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com