Method for producing synthetic rutile by using deluvial slope type ilmentie

An artificial rutile and ilmenite technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of unsuitable boiling chlorinated raw materials, low grade of artificial rutile, low softening point at high temperature, etc., and achieve easy continuous production , The equipment material is easy, the effect of high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

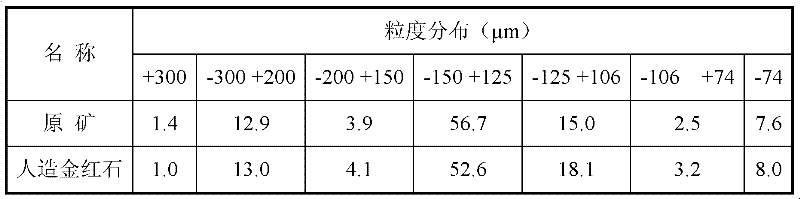

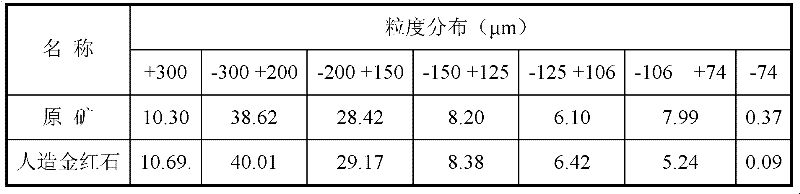

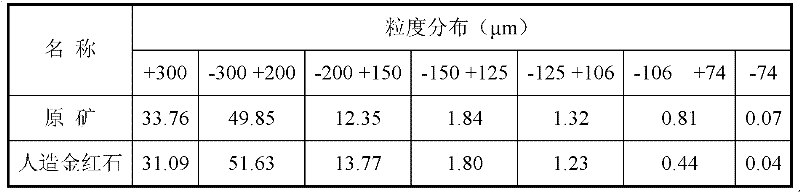

[0023]A method for producing artificial rutile with residual slope-type ilmenite of the present invention, the method is to use 400g Yunnan residual slope-type ilmenite as raw material (see table 1 below for its chemical composition, see table 2 below for particle size composition) , including the following steps:

[0024] (1) Reduction pretreatment: first place ilmenite in a rotary kiln, use coal as a reducing agent, and perform reduction treatment at a temperature of 850°C for 30 minutes;

[0025] (2) Oxidation pretreatment: Transfer the discharge after the above reduction pretreatment to the muffle furnace for oxidation treatment. The oxidant used is oxygen. The temperature during the oxidation treatment is controlled at 800-850°C. The shell of rutile microcrystals and iron-rich layer is formed; the roasted material to be oxidized is cooled to 90°C to complete the oxidation process;

[0026] (3) Fluidized acid leaching: send the above-mentioned oxidized pretreated ore into...

Embodiment 2

[0034] A method for producing artificial rutile with residual slope-type ilmenite of the present invention, the method is to use 400g Guangxi residual slope-type ilmenite as raw material (see table 3 below for its chemical composition, see table 4 below for particle size composition) , including the following steps:

[0035] (1) Reduction pretreatment: first place ilmenite in a rotary kiln, use coal as a reducing agent, and perform pre-reduction treatment at a temperature of 900°C for 15 minutes;

[0036] (2) Oxidation pretreatment: Transfer the output after the above reduction pretreatment to the muffle furnace for oxidation treatment, the oxidant used is oxygen, and the temperature during the oxidation treatment is controlled at 800°C (the parameters have been changed to distinguish it from the original patent), after 25 minutes of oxidation treatment, rutile microcrystals and iron-rich shells are formed on the surface of the mineral; the roasted material to be oxidized is c...

Embodiment 3

[0045] A method for producing artificial rutile with residual slope-type ilmenite of the present invention, the method is to use 400 grams of Guangxi altered ilmenite as raw material (see table 5 below for its chemical composition, and table 6 below for particle size composition), Include the following steps:

[0046] (1) Reduction pretreatment: first place ilmenite in a rotary kiln, use coal as a reducing agent, and perform pre-reduction treatment at a temperature of 850°C for 215 minutes;

[0047] (2) Oxidation pretreatment: Transfer the above-mentioned reduced output to the muffle furnace for oxidation treatment. The oxidant used is oxygen. The temperature during the oxidation treatment is controlled at 800 ° C. After 10 minutes of oxidation treatment, there are rutile crystallites and The iron-rich shell is formed; the roasted material to be oxidized is cooled to 90°C to complete the oxidation process;

[0048] (3) Fluidized acid leaching: the above-mentioned pretreated o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com