Underflow type constructed wetland system with coke powder-steel slag compound filler

A technology of constructed wetland system and composite filler, which is applied in the field of subsurface constructed wetland sewage treatment system and sewage treatment system, can solve the problems of low effective utilization rate, low added value, large amount of steel slag, etc., achieves superior adsorption effect, reduces treatment Cost, unbreakable effect

Inactive Publication Date: 2010-10-06

BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Steel slag is waste slag from steelmaking furnaces in iron and steel plants. It is mainly used as building materials and road subgrades. However, the slag produced in iron and steel plants every day, especially steel slag, has a large amount of effective utilization, and the added value of traditional utilization methods is also low, so it is urgently needed Open up new avenues of utilization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

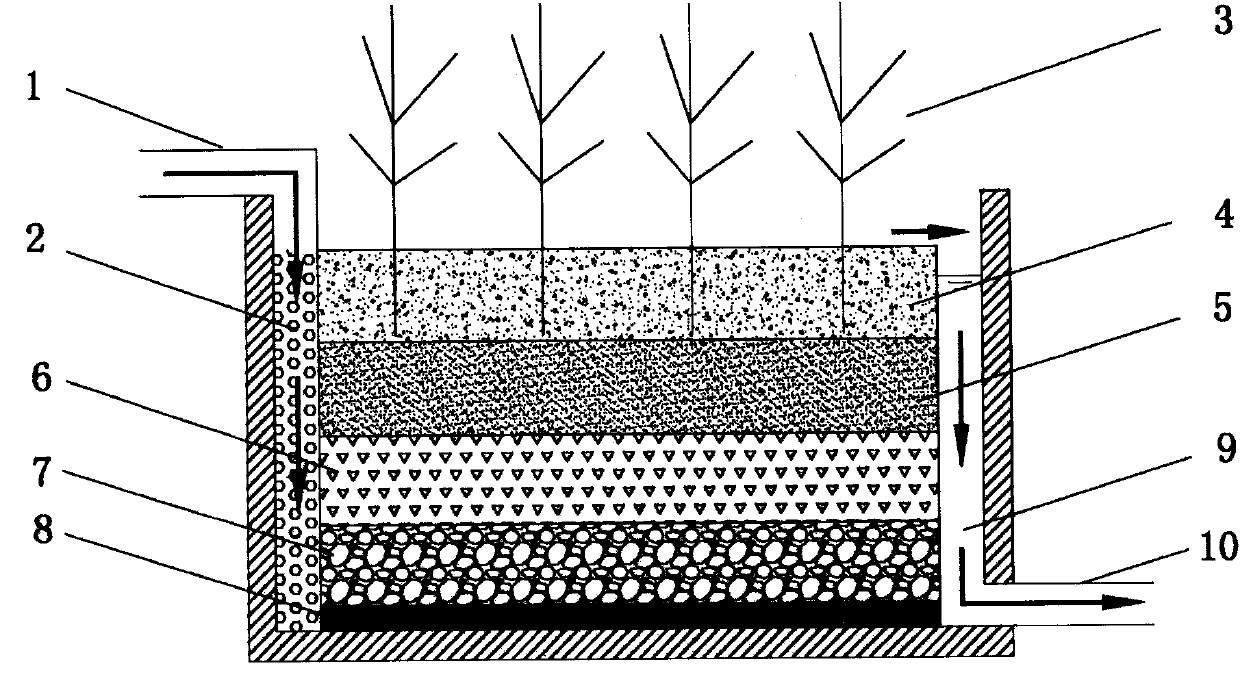

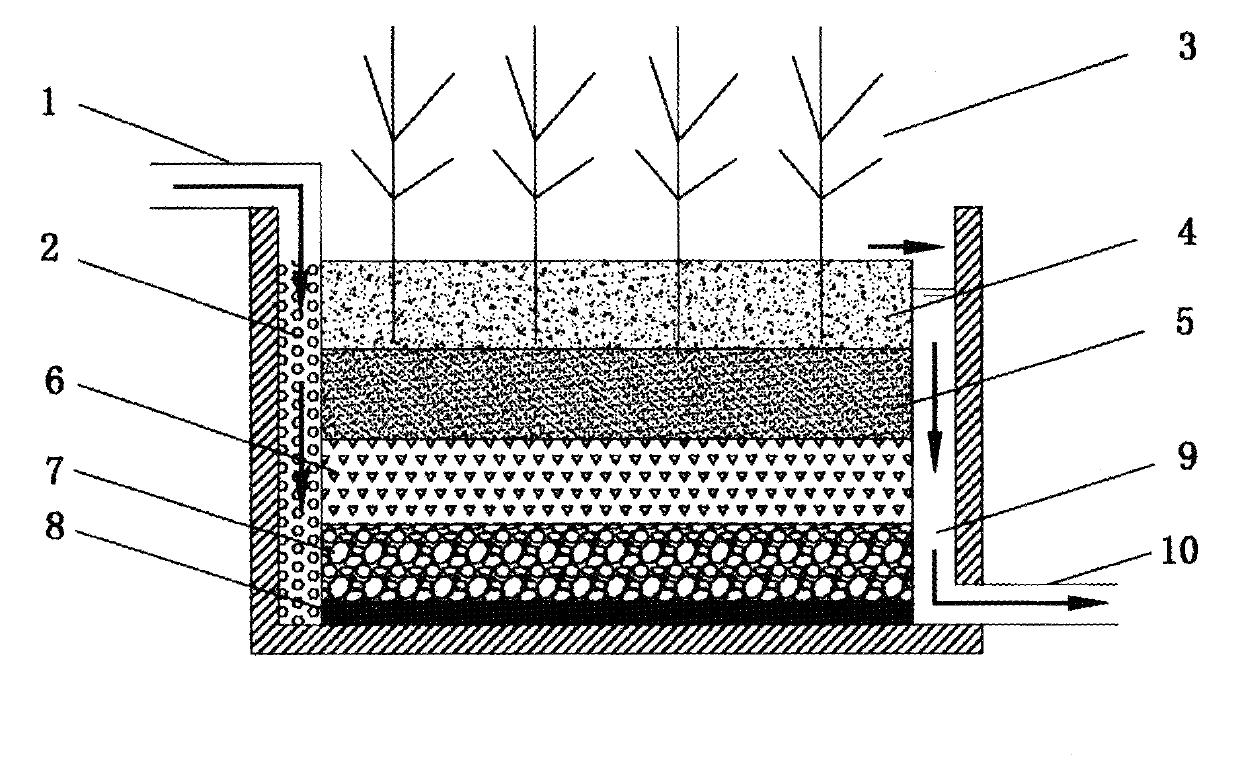

The invention provides a sewage treatment system of an underflow type constructed wetland based on disadvantages of the prior art. The sewage treatment system adopts coke powder-steel slag as compound filler, and has the advantages of simple structure, convenient management, no easy blockage and good denitrification and dephosphorization effect, thereby enhancing the treatment effect of sewage of the constructed wetland and improving the quality of the secondary effluent of the urban sewage treatment plant. The system mainly comprises a water inlet pipe, a water distribution area, an underflow type constructed wetland tank body, a coke powder-steel slag compound filler bed, a catchment area, a water outlet pipe and the like, wherein the coke powder-steel slag compound filler bed arranged in the sewage treatment system of the underflow type constructed wetland is provided with a sand soil covering layer, coke powder, steel slag and gravels in sequence from top to bottom, aquatic plants which have high capability of sewage purification and are suitable for local environmental conditions are grown on the sand soil covering layer, and the bottom of the filler bed adopts an impermeable layer made of natural clay as a waterproof structure.

Description

Technical field: The invention relates to a sewage treatment system, in particular to an underflow constructed wetland sewage treatment system using coke powder-steel slag as composite fillers, and belongs to the field of environmental protection. Background technique: Constructed wetland sewage treatment system is a sewage treatment technology developed in the 1970s. Compared with the traditional sewage secondary biochemical treatment process, it has good purification effect, simple process equipment, convenient operation and maintenance management, low energy consumption, and systematic The characteristics of strong configuration plasticity, strong adaptability to load changes, low engineering infrastructure and operating costs, certain biological safety of effluent, remarkable ecological and environmental benefits, and the realization of sewage resources are attracting more and more people's attention. Its disadvantage is that it occupies a large area and is prone to prob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F3/32C02F3/34C02F3/30

CPCY02W10/10

Inventor 吴盟盟王晓婵王皓张鑫

Owner BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com