Thermoacoustic refrigeration device of automobile

A technology of thermoacoustic refrigeration and automobiles, which is applied in refrigerators, refrigeration and liquefaction, and machines using waste heat, etc. It can solve the problems of very strict vacuum degree, risk of crystallization, and few mechanical moving parts, and achieve effective protection. Avoid the greenhouse effect, avoid the effect of underpowered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

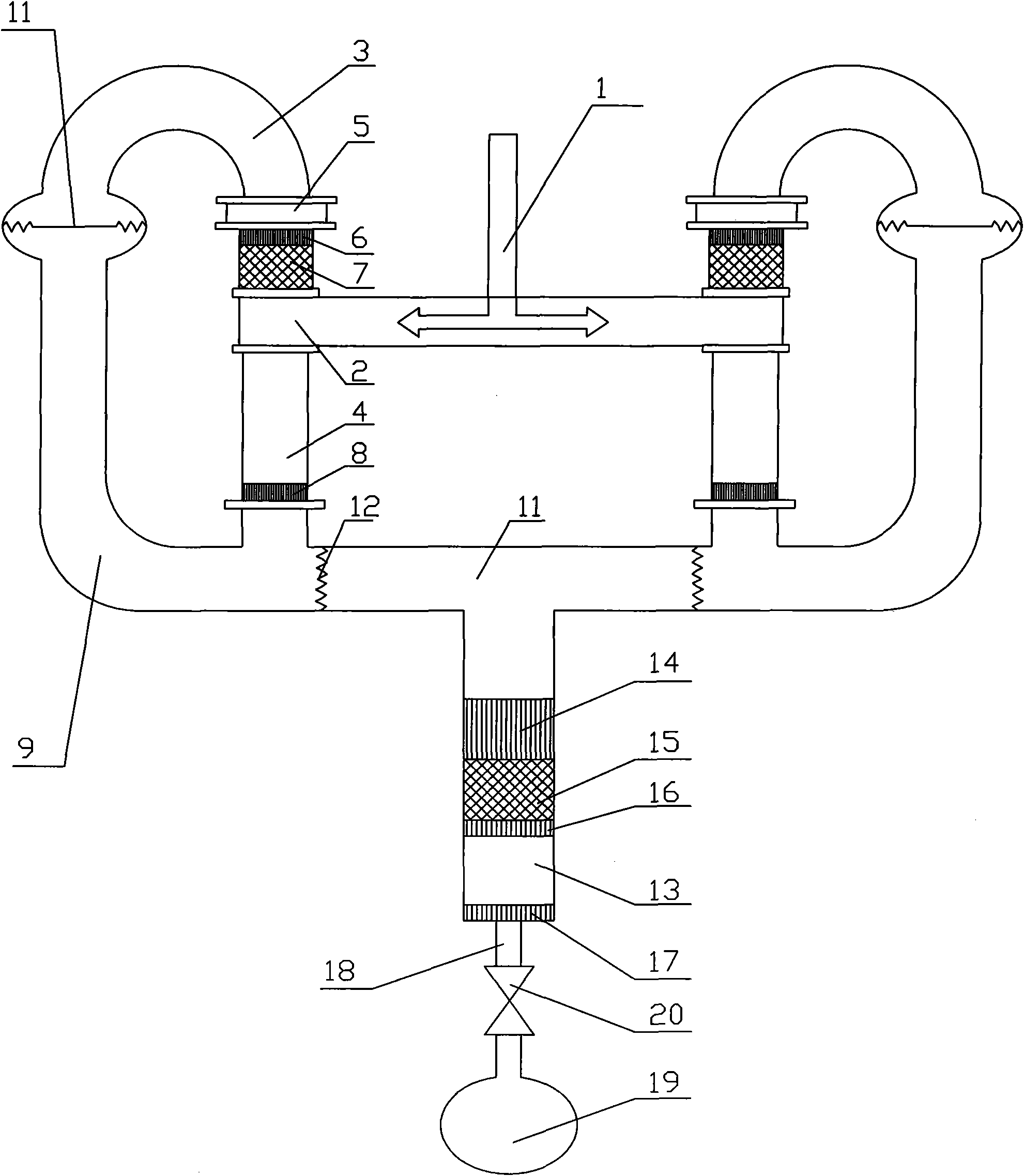

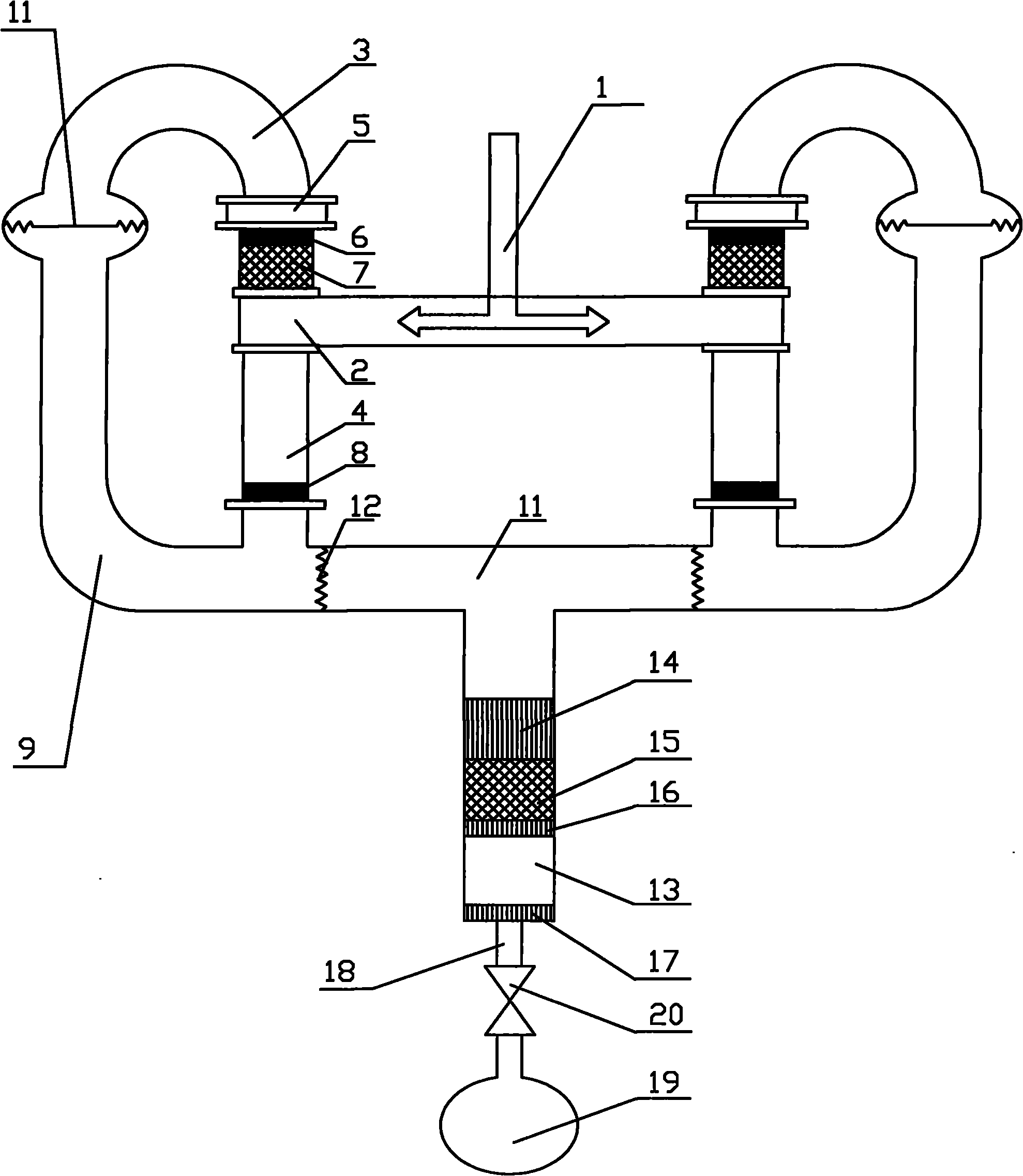

[0014] Such as figure 1 As shown, the thermoacoustic cooling device of the automobile comprises: the automobile exhaust waste heat heater 2 connected with the automobile exhaust pipe 1, and the two ends of the automobile exhaust waste heat heater 2 are respectively provided with a sound volume tube 3 and a thermal buffer Tube 4, between one end of the sound volume tube 3 and the exhaust gas waste heat heater 2, a jet pump 5, a heat-generating heat-regenerating end cooler 6 and a thermoacoustic regenerator 7 are arranged in sequence, and a thermal buffer tube 4 is provided with In the diversion cooler 8, the other end of the sound capacity tube 3 is connected to one end of the feedback tube 9, and an anti-DC elastic diaphragm 10 is arranged between the sound capacity tube 3 and the feedback tube 9, and the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com