Etofenprox emulsified powder and manufacture method

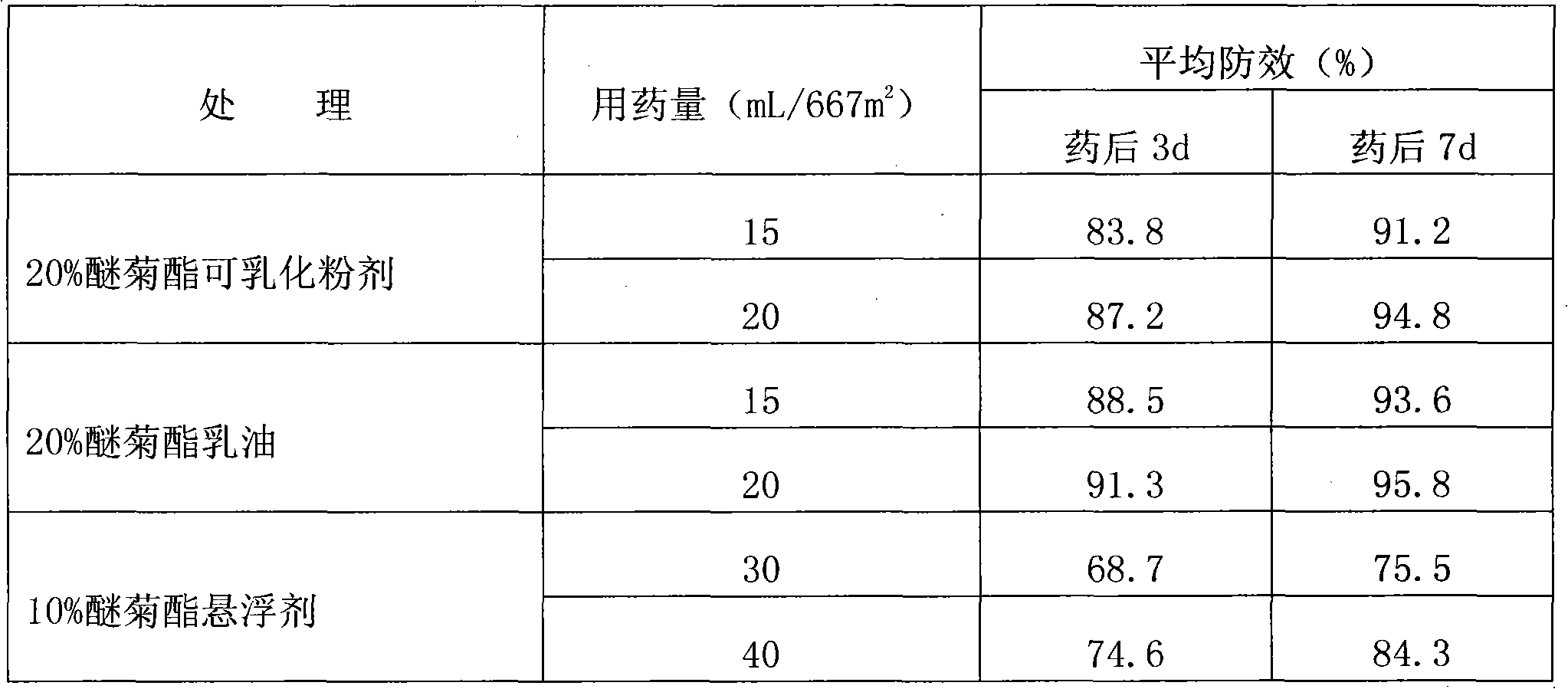

A manufacturing method, the technology of etofenprox, which is applied in the field of emulsifiable powder of etofenprox and its manufacture, can solve the problems of poor storage stability of suspensions, less efficacy than emulsifiable concentrates, unsafe hidden dangers, etc., so as to avoid harm to people and the environment Hazard, storage and transportation safety, environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example is 20% Etofenprox emulsifiable powder.

[0033] It is composed of the following raw materials in weight percentage: 20% of etofenproxil, 4% of xylene, 6% of agricultural milk (0201B), 3% of agricultural milk (700), 40% of white carbon black, 3% of sodium lignosulfonate, silicon Alite is topped up to 100%.

[0034] The production method is as follows: mix etherproxil and solvent evenly, the mixed liquid is adsorbed on the carrier, and then mixed evenly with the wetting and dispersing agent; the mixed raw materials are pulverized by a jet mill to make the particle size reach 98%. 45μm mesh.

Embodiment 2

[0036] This example is 25% Etofenprox emulsifiable powder.

[0037] Composed of the following raw materials in weight percent: Etoproxil 25%, xylene 5%, Nongru (0201B) 5%, Nongru (BY110) 4%, white carbon black 45%, dispersant (D425) 3%, concave-convex Stick clay topped up to 100%.

[0038] The production method is as follows: uniformly mix etofenproxil, solvent, and wetting and dispersing agent, and the mixed liquid is adsorbed on the carrier; the mixed raw materials are pulverized by a jet mill, so that the particle size reaches 98% and passes through a 45 μm sieve hole .

Embodiment 3

[0040] This example is 5% Etofenprox emulsifiable powder.

[0041] Composed of the following raw materials in weight percentage: 5% etofenproxil, 1% xylene, 8% agricultural milk (0201B), 2% agricultural milk (1601), 10% white carbon black, 3% sodium lignosulfonate, bentonite Top up to 100%.

[0042] The manufacturing method is the same as in embodiment one or embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com