Method for treating dry distillation sewage of oil shale

A sewage treatment and oil shale technology, applied in the field of environmental protection and petrochemical industry, can solve the problems of expensive treatment cost, difficult separation of catalyst and liquid, and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Preparation of catalyst

[0022] Industrial titanium sulfate solution (TiO 2 140g / L, Ti 3+ 1.17g / L, Fe 2+ 43g / L, Cr 3+ 0.23g / L, Mn 2+ 0.45g / L, F is 312g / L), EDTA is A.R. grade. Prepare 0.05mol / L titanium sulfate solution, put 1000mL in a beaker, add 50mL of 0.01mol / L EDTA solution under stirring condition, let stand for 30 minutes, adjust with 0.1mol / L sodium hydroxide solution The pH value of the solution, until a white precipitate appears, heat it in a water bath to 80°C for 2 hours, wash the precipitate until there is no SO 4 - Until then, dry to obtain powder, and roast the obtained TiO at a temperature of 580-600°C 2 .

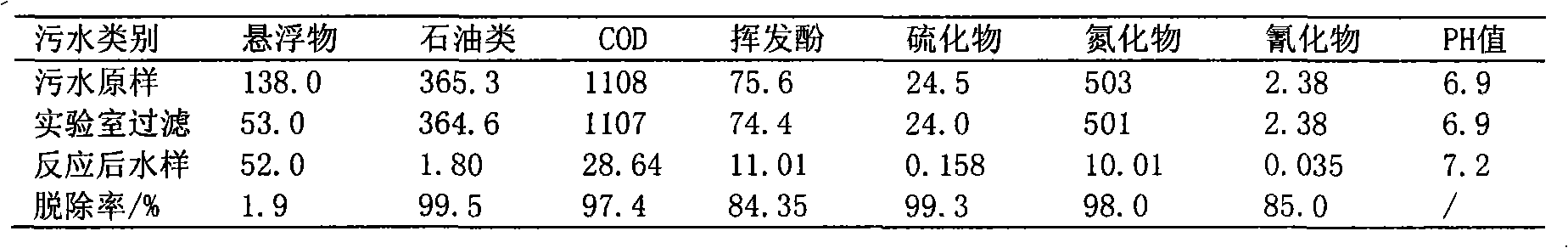

[0023] 2. Catalytic degradation of dry distillation sewage

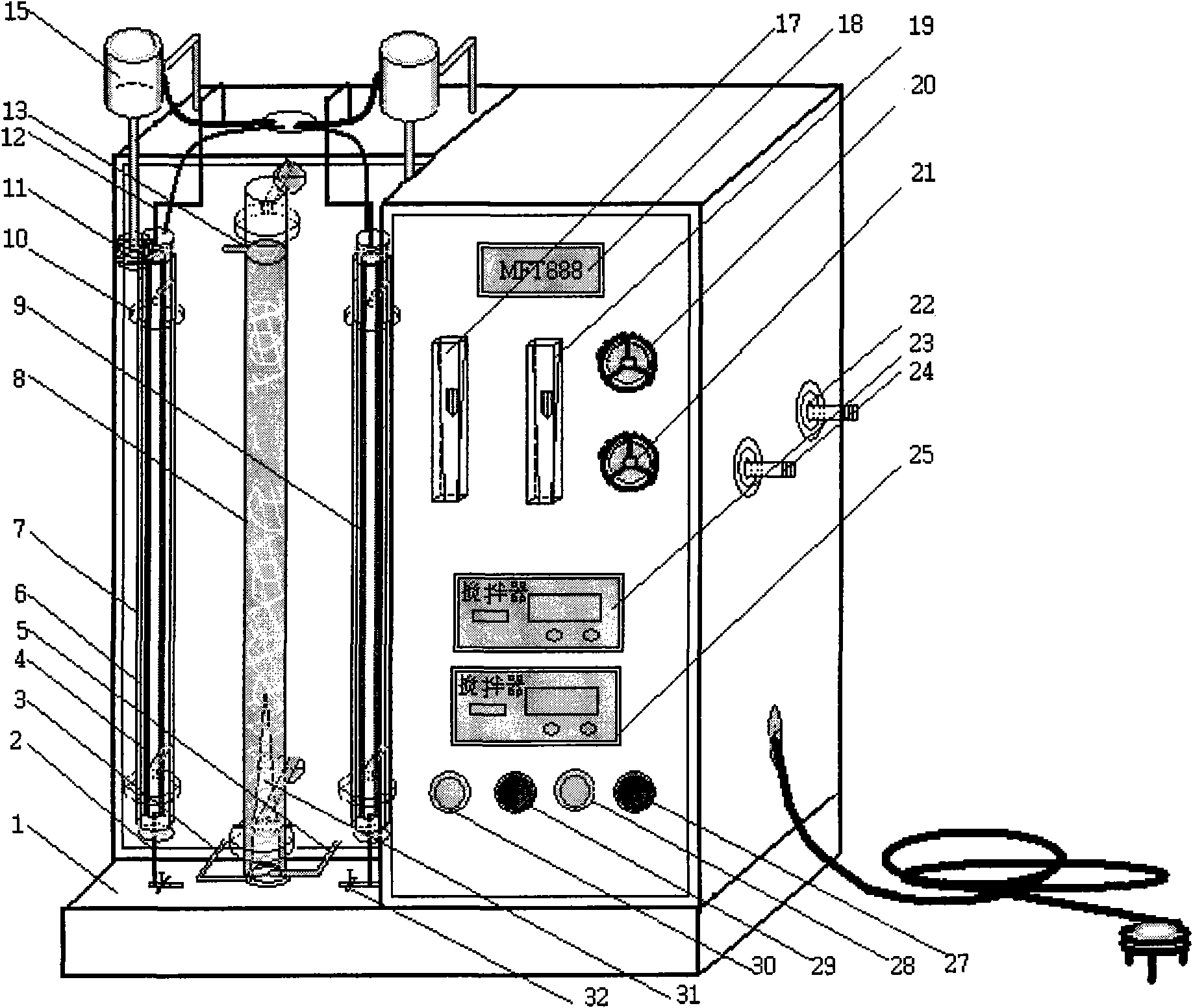

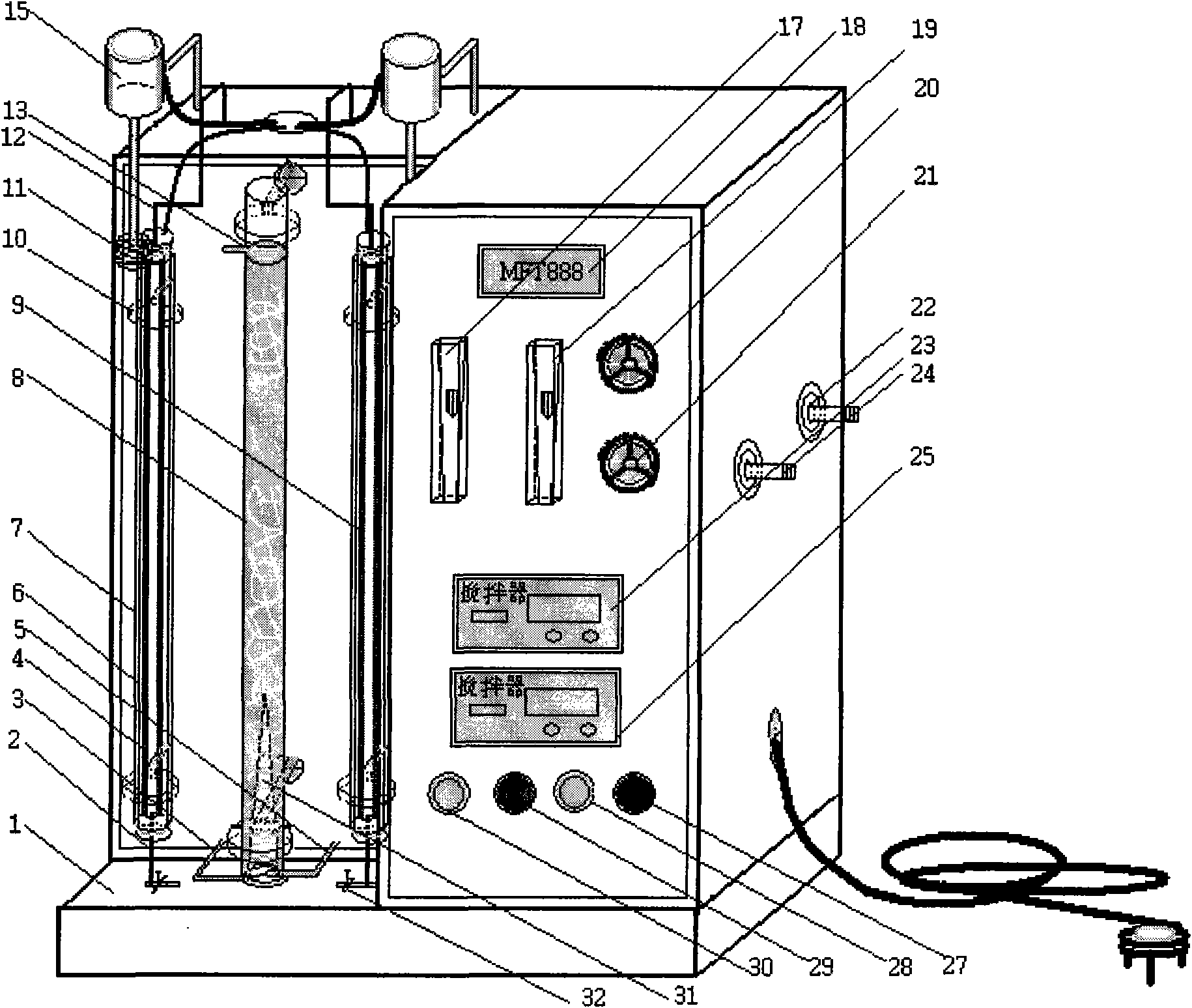

[0024]Using a self-made photocatalytic device to degrade oil shale retort wastewater. The device mainly includes a fixed bracket 1 at the bottom, a motor 15, a reaction device, and a chassis, wherein the reaction device mainly includes a left ultraviolet lamp tube 4, a reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com