High-power semiconductor laser optical output module capable of being reused

An output module and laser technology, applied in the field of lasers, can solve the problems of asymmetry of semiconductor laser bar light spots, increase of system cost and difficulty of debugging, high cost of beam conversion system, etc., to achieve small size, power increase, volume reduction and effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

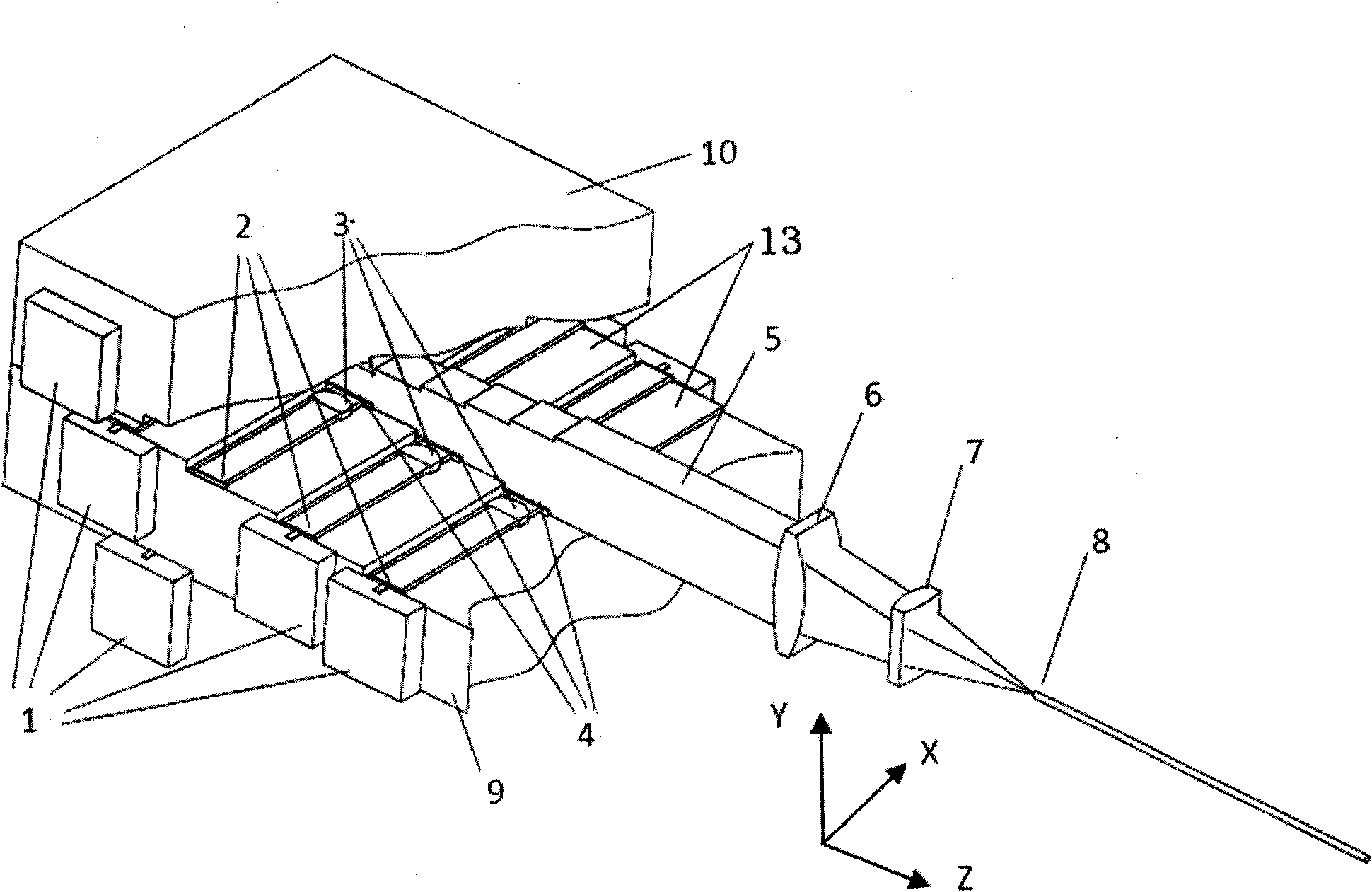

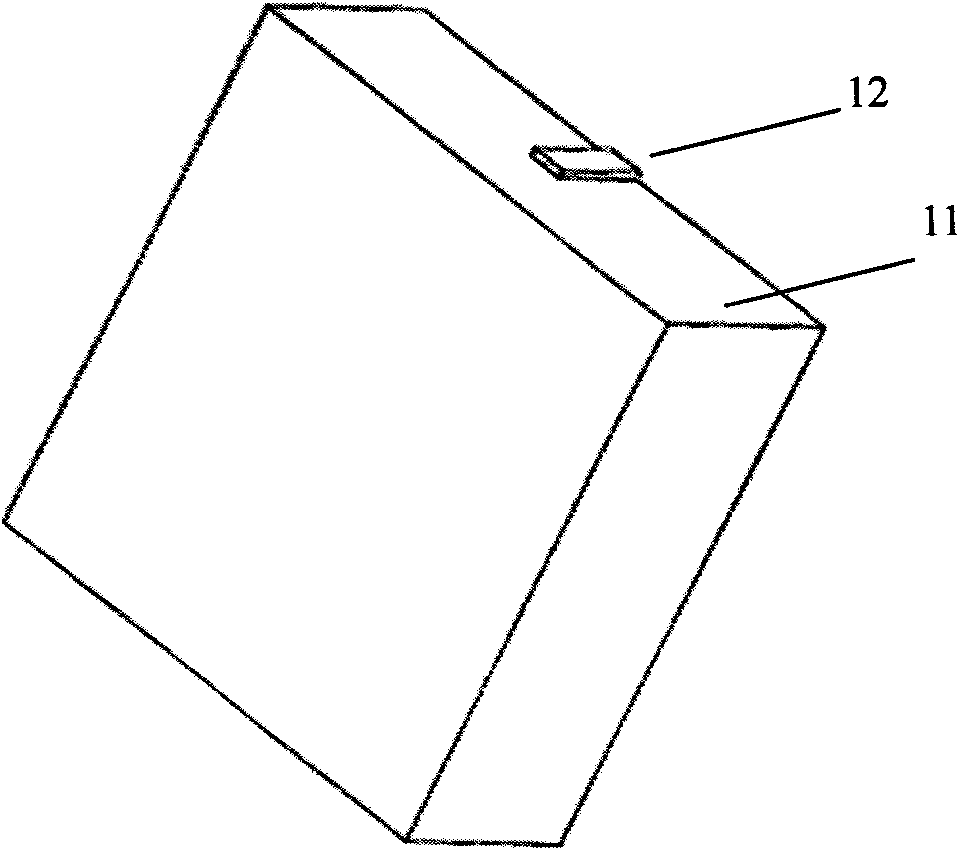

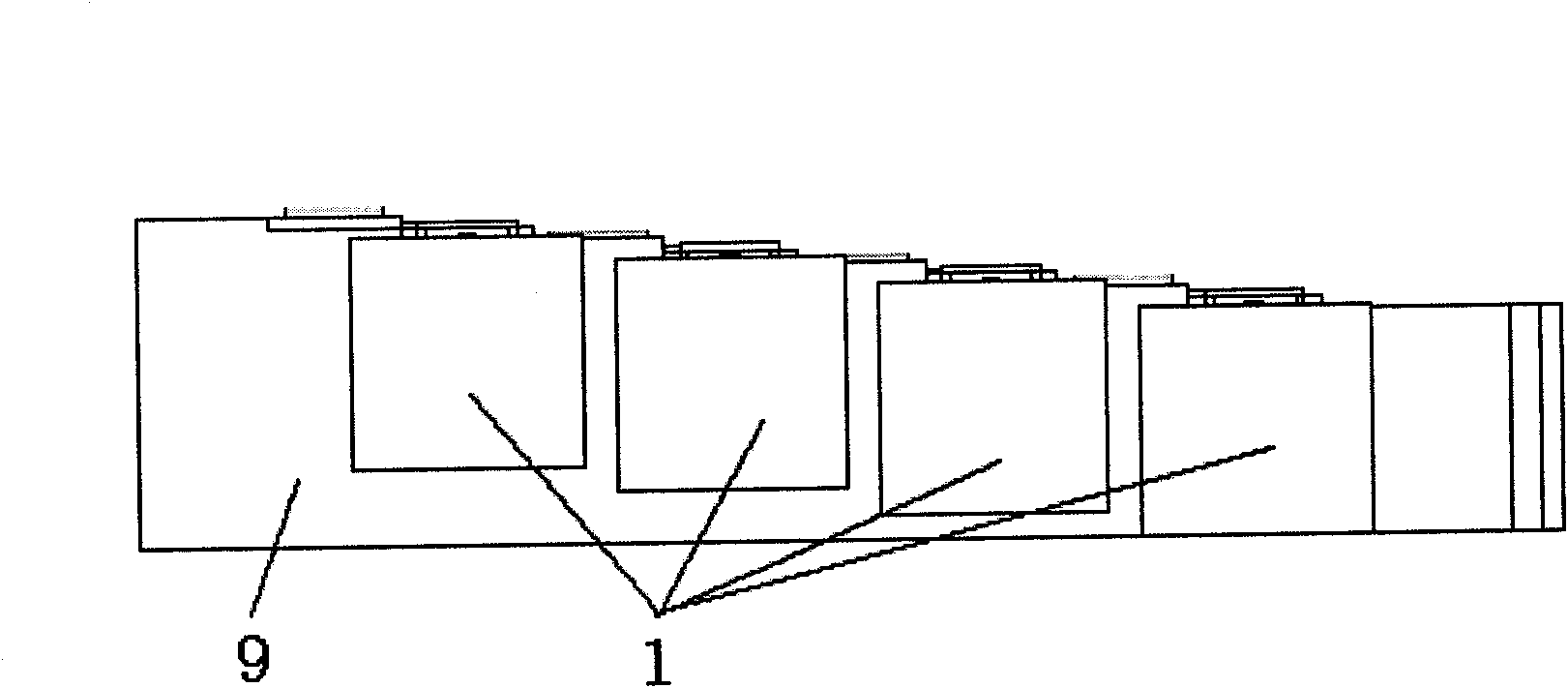

[0017] Depend on Figure 1-7 As shown, the present invention includes a laser beam shaping system, a focusing system, an upper stepped base 10, and a lower stepped base 9. The upper stepped base 10 and the lower stepped base 9 are fastened through each other's upper end surfaces, and the laser beam shaping system is installed on the upper, lower stepped base 9. On the steps 13 of the lower stepped base, the focusing system is located in the direction of the outgoing light outside the upper and lower stepped bases. The steps 13 on the said lower stepped base 9 are staggered, and the steps 13 on different sides are in the middle of the lower stepped base 9. The contact surface is V-shaped, and the contact surface of the whole step 13 is V-shaped wave. The said upper stepped base 10 has the same structure as the lower stepped base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com