Piezoelectric twin-wafer type MEMS energy collector and preparation method thereof

A piezoelectric bimorph, energy harvester technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. It can solve the problems of repeated charging, large volume, and energy exhaustion, and achieve the effect of simple and reliable preparation method, wide application prospects, and improved conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

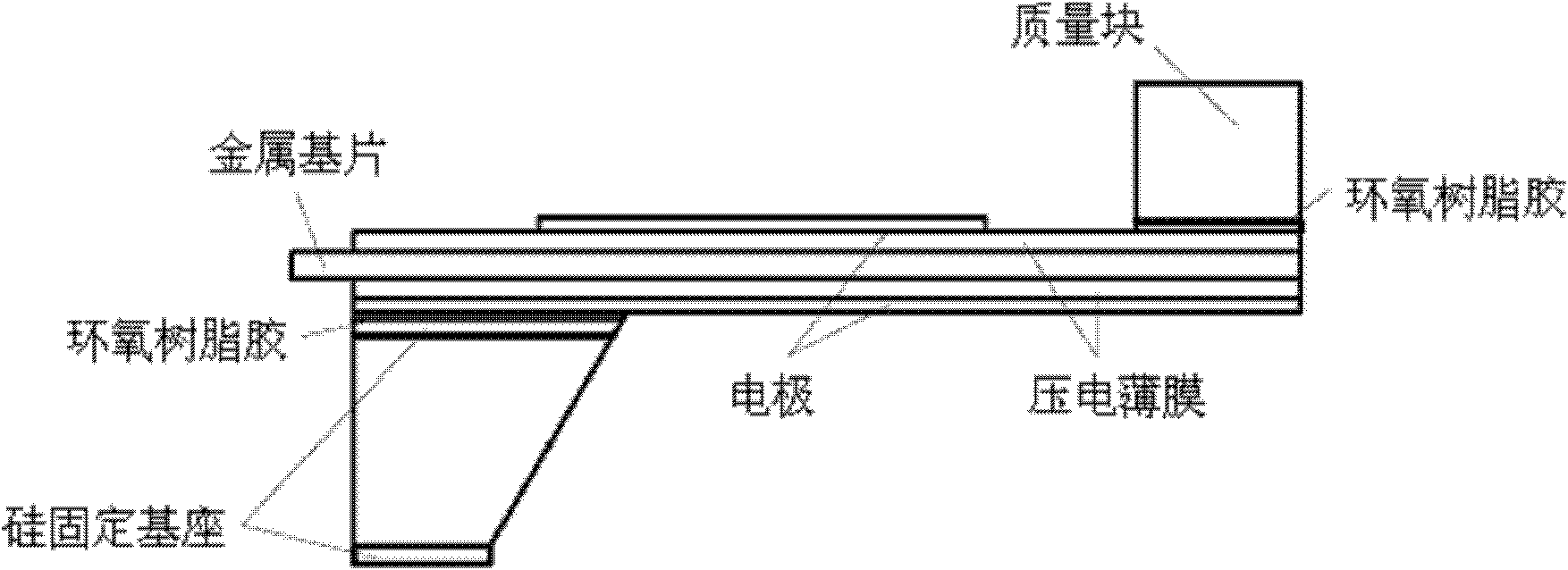

[0037] The piezoelectric bimorph MEMS energy harvester that this embodiment relates to includes: some piezoelectric bimorph cantilever beams, such as figure 1 As shown, each piezoelectric bimorph cantilever beam includes: a silicon fixed base, a piezoelectric bimorph and a mass block, wherein: one end of the piezoelectric bimorph is fixed on the silicon fixed base, and the other end of the piezoelectric bimorph is suspended , the mass block is fixed on the suspended end of the piezoelectric bimorph.

[0038] The mass block is a nickel metal block.

[0039] The piezoelectric bimorph includes: a metal substrate, two layers of piezoelectric film and two layers of electrodes, wherein: the first layer of piezoelectric film is located on the upper surface of the metal substrate, and the second layer of piezoelectric film is located on the surface of the metal substrate. On the lower surface, the first layer of electrodes is located on the upper surface of the first layer of piezoel...

Embodiment 2

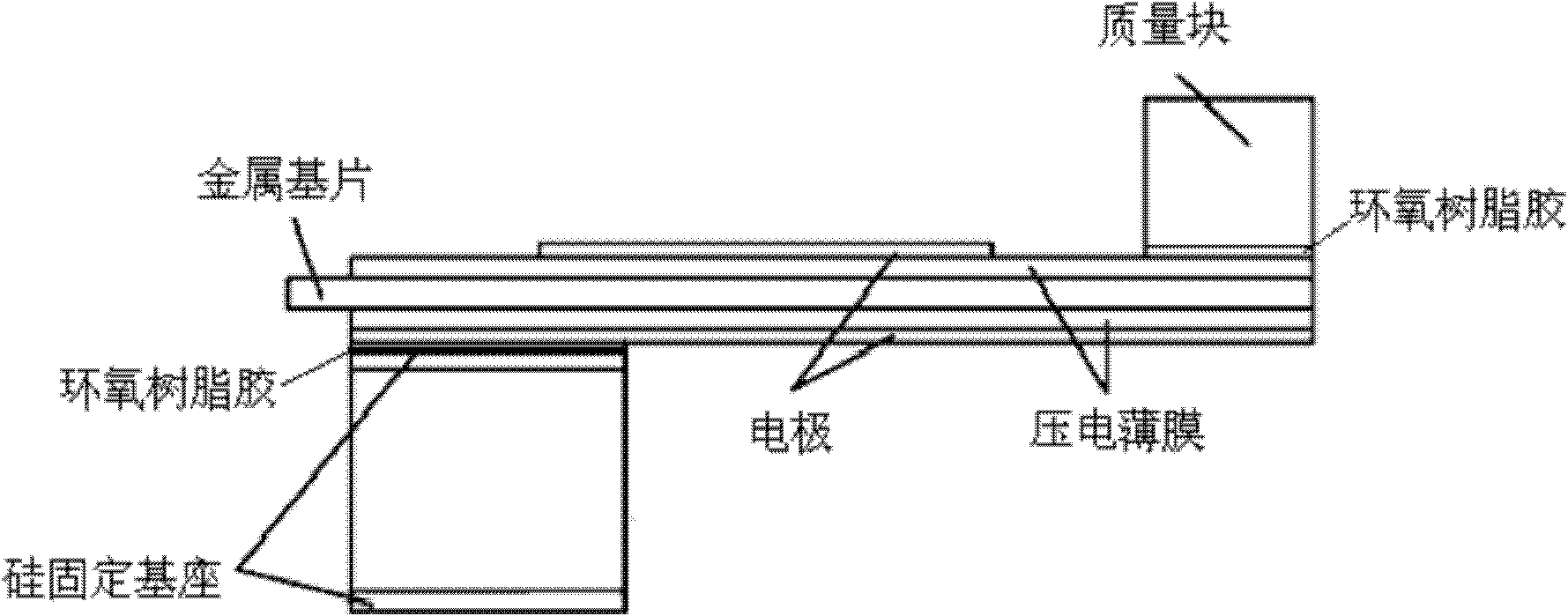

[0063] The piezoelectric bimorph MEMS energy harvester that this embodiment relates to includes: some piezoelectric bimorph cantilever beams, such as image 3 As shown, each piezoelectric bimorph cantilever beam includes: a silicon fixed base, a piezoelectric bimorph and a mass block, wherein: one end of the piezoelectric bimorph is fixed on the silicon fixed base, and the other end of the piezoelectric bimorph is suspended , the mass block is fixed on the suspended end of the piezoelectric bimorph.

[0064] The mass block is a nickel metal block.

[0065] The piezoelectric bimorph includes: a metal substrate, two layers of piezoelectric film and two layers of electrodes, wherein: the first layer of piezoelectric film is located on the upper surface of the metal substrate, and the second layer of piezoelectric film is located on the surface of the metal substrate. On the lower surface, the first layer of electrodes is located on the upper surface of the first layer of piezoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com