Surface mount adhesive for use in lead-free packaging process and preparation method

A packaging technology, lead-free solder technology, applied in the direction of electrical components assembly printed circuit, adhesive, epoxy resin glue, etc., can solve the problems that are difficult to meet high-speed printing and lead-free solder packaging, high soldering temperature, etc., to achieve good Glue dispensing performance, moderate height, and the effect of glue dots not flowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

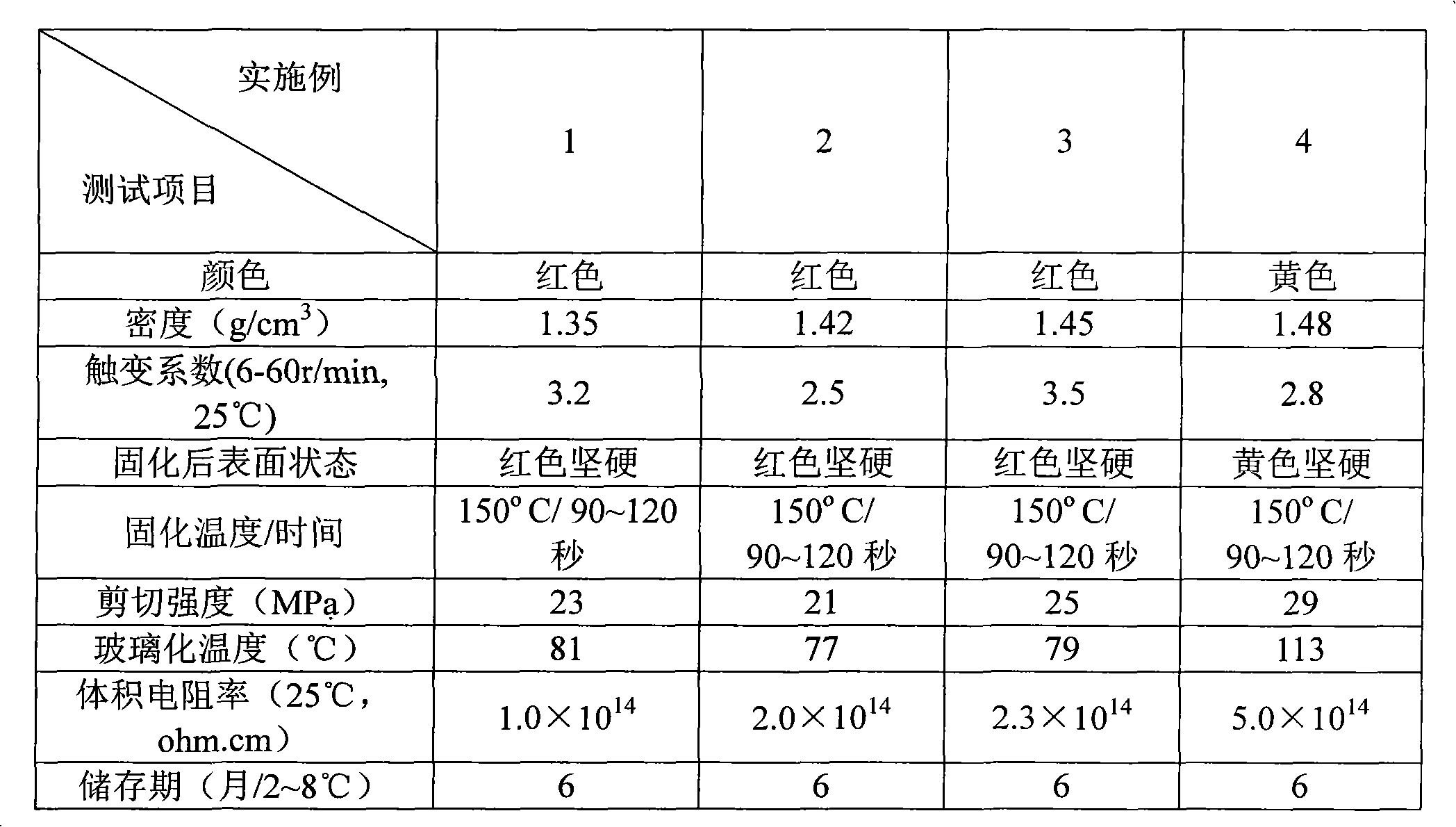

Examples

Embodiment 1

[0027] The components of patch adhesive and the content of each part are as follows:

[0028] p-tert-Butylphenyl glycidyl ether 18.4

[0029] Glycidyl tert-carbonate E10P 2.6

[0030] Latent curing agent PN-23 12.3

[0031] Latent curing agent PN-40 6.7

[0032] Fumed silica 7.5

[0033] Red Pigment (Permanent Red) 3

[0034] Light calcium carbonate 10.5

[0035] Microsilica 8.0

[0036] Epoxy resin E51 31

[0037] Specific preparation method:

[0038] Add epoxy resin E51, p-tert-butylphenyl glycidyl ether, glycidyl tert-carbonate E10P, and thixotropic agent (fumed silica) into the planetary power mixer according to the formula ratio and mix and stir for 25 minutes to form a paste Grind for 3 times with a three-roll mill, then add fillers such as light calcium carbonate, silicon micropowder, colorants, latent curing agents PN-23 and PN-40, etc. and stir evenly, then perform vacuum defoaming treatment, and stir for 1 hour After degassing, the patch glue shown is obtain...

Embodiment 2

[0040] Glycidyl tert-carbonate E10P 8.0

[0041] Latent curing agent PN-23 15.3

[0042] MY-24 3.2

[0043] Fumed silica 10.0

[0044] Red Pigment (Permanent Red) 2.0

[0045] Light calcium carbonate 15.0

[0046] Epoxy resin E51 38

[0047] Phenolic epoxy resin DEN438 8.5

[0048] Specific preparation method:

[0049] Add epoxy resin E51, phenolic epoxy resin DEN-438, glycidyl tertiary carbonic acid ester E10P, thixotropic agent (gas phase silica) into the planetary power mixer according to the formula ratio and mix for 25 minutes to form a paste , grind 3 times with a three-roll mill, then add filler light calcium carbonate, colorant, latent curing agent PN-23, MY 24, etc. and stir evenly, then perform vacuum defoaming treatment, stir for 1 hour to degas, and get Adhesives shown.

Embodiment 3

[0051] Thinner Heloxy48 9.0

[0052] Glycidyl tert-carbonate E10P 6.5

[0053] Latent curing agent PN-40 14.0

[0054] MY-24 25

[0055] Fumed silica 4.5

[0056] Red pigment (permanent red) 2.8

[0057] Silica powder 23.9

[0058] Epoxy resin E51 25.6

[0059] Epoxy resin E54 11.2

[0060] Specific preparation method:

[0061] Add epoxy resin E51 and E54 in the planetary dynamic mixer according to the formula ratio, glycidyl tertiary carbonic acid ester E10P, diluent Heloxy 48, thixotropic agent (fumed silica) and mix and stir for 25min to form a paste, use Grind three times with a three-roll mill, then add filler silica powder, colorant, latent curing agent PN-40, MY-24, etc. and stir evenly, then perform vacuum defoaming treatment, stir for 1 hour to degas, and the paste shown in the figure is obtained Sheet glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com