Method for detecting sulfur dioxide in food

A technology for sulfur dioxide and food, applied in the measurement of color/spectral characteristics, etc., can solve the problems of low cost, complicated processing operation, long time consumption, etc., and achieve the effect of high degree of automation, accurate detection results, and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

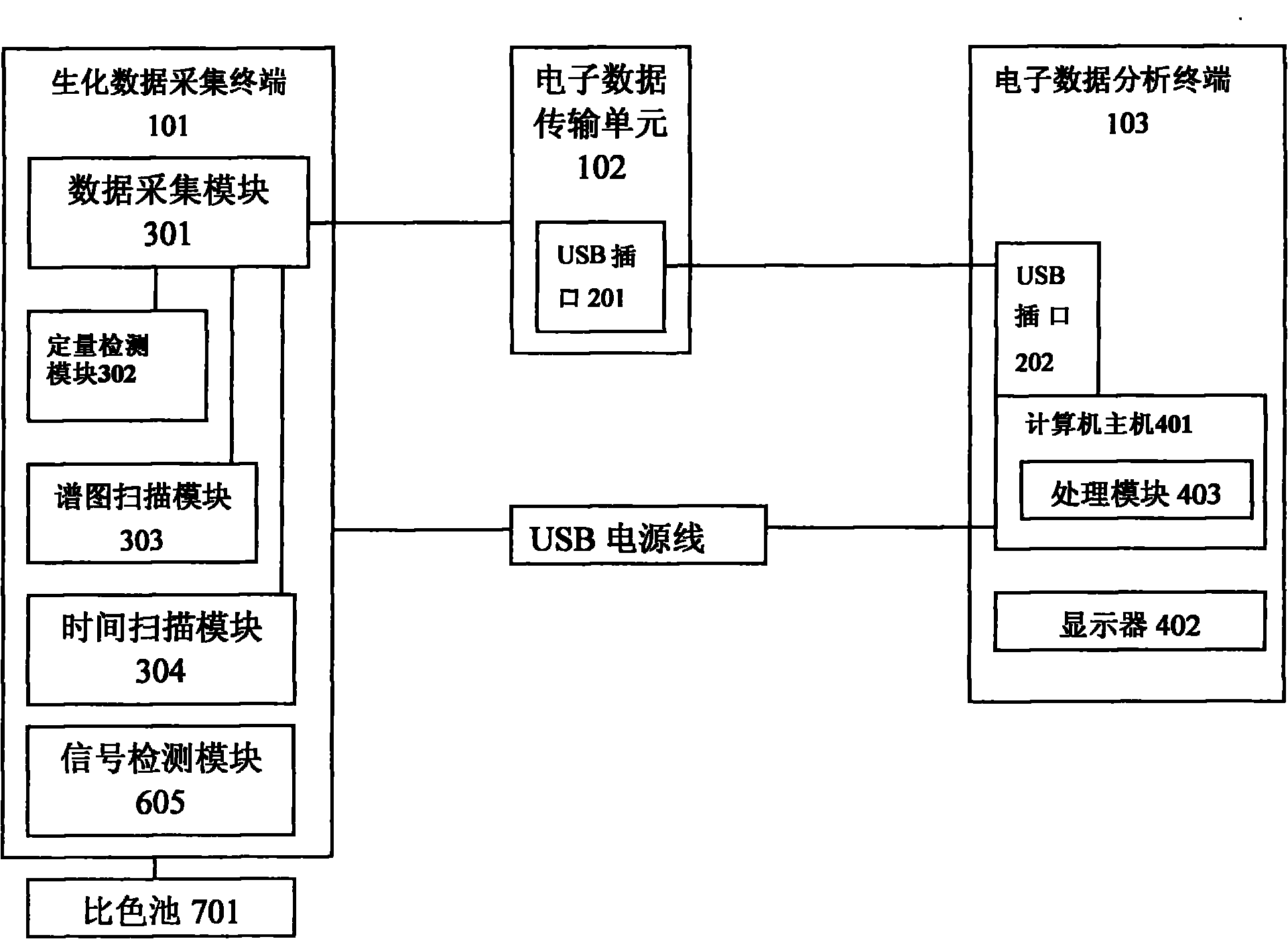

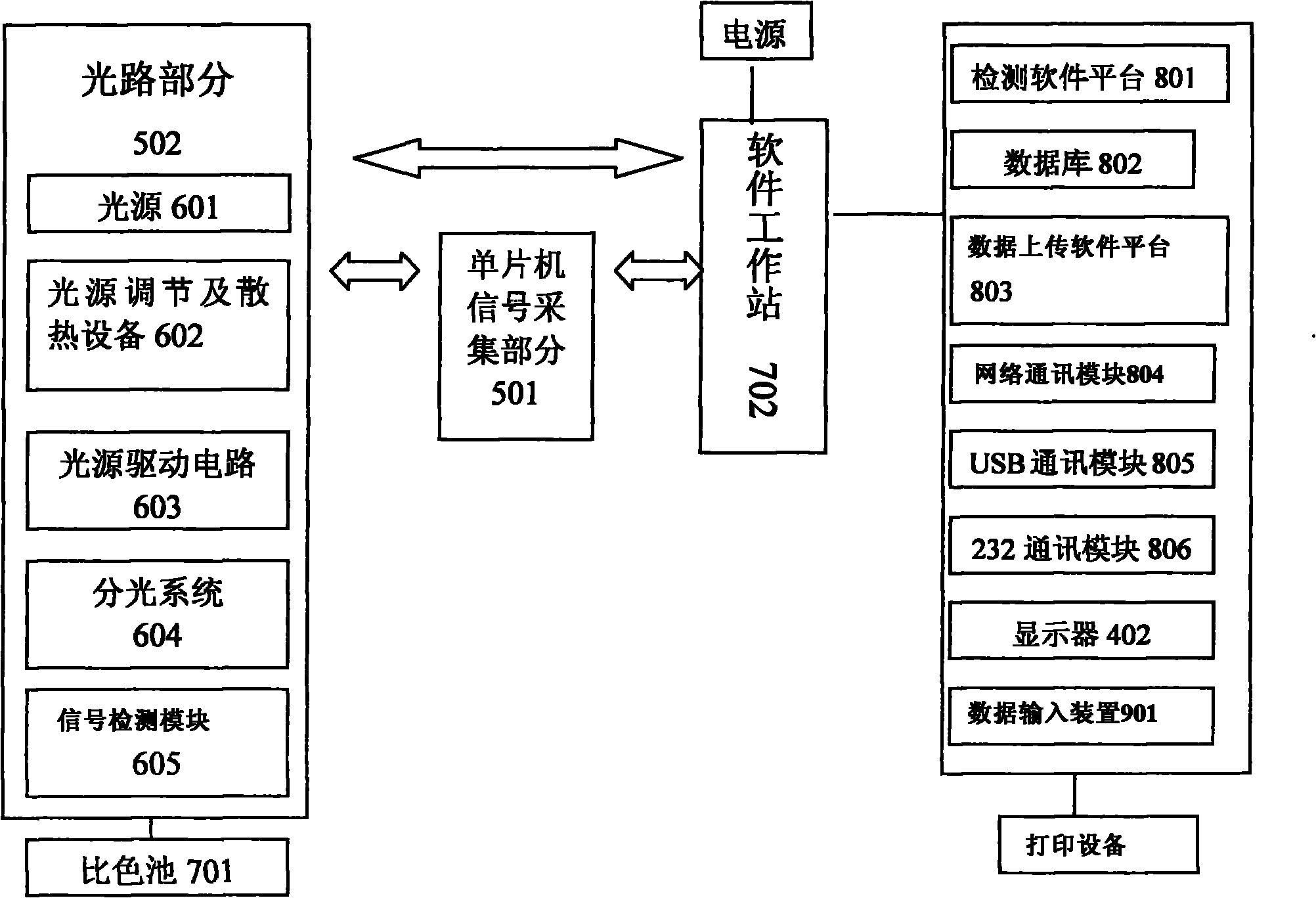

Method used

Image

Examples

Embodiment 1

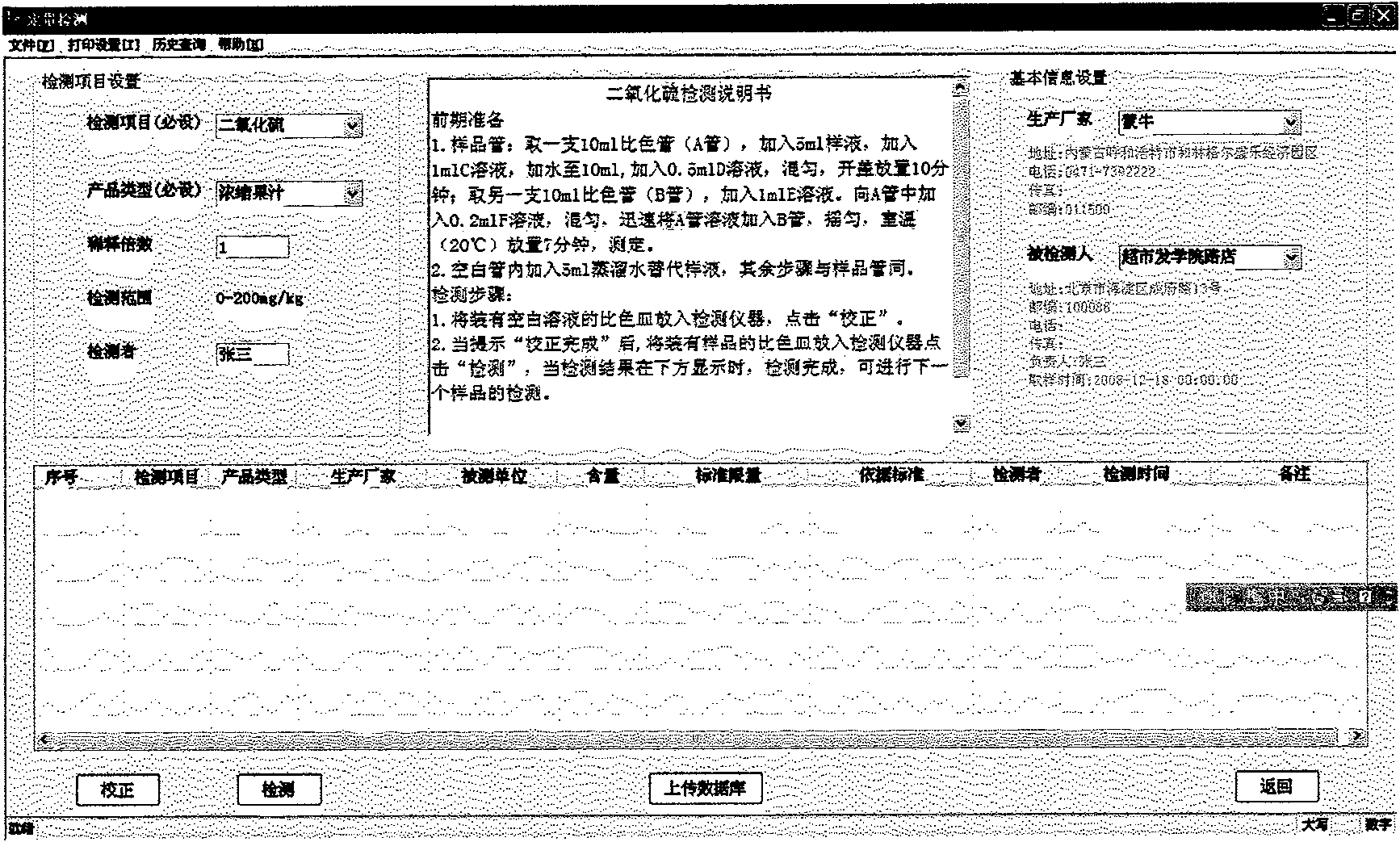

[0054] Example 1 Detect the sulfur dioxide content in white granulated sugar by using the PCS multi-functional food safety rapid detector: weigh 2.5 g of white granulated sugar, add water to dissolve, dilute to 50 mL, shake well and set aside. Turn on the machine, enter the main detection interface of the PCS multi-function food safety rapid detector, click the "food quality analysis" module, enter the "quantitative detection" interface, set the "test item" to sulfur dioxide, and the "product type" to white sugar. Then follow the steps of the "Sulfur Dioxide Detection Manual" on the "Quantitative Detection" interface of the instrument software. Finally, the detection result is directly read out on the detection interface. Results can be saved, printed and uploaded.

[0055] The steps of the "Sulfur Dioxide Detection Manual" are as follows:

[0056] ①Sample tube: Take a 10mL colorimetric tube (A tube), add 5mL sample solution, add 1mL LC solution, add water to 10mL, add 0.5mL...

Embodiment 2

[0060] Example 2 Use the PCS multi-function food safety rapid detector to detect the sulfur dioxide content in the concentrated fruit juice: take 1 mL, add water to make the volume to 20 mL, shake well, further dilute if the concentration is high, and filter for later use if necessary. Turn on the machine, enter the main detection interface of the PCS multi-function food safety rapid detector, click the "food quality analysis" module, enter the "quantitative detection" interface, set the "test item" to sulfur dioxide, and the "product type" to white sugar. Then follow the steps of the "Sulfur Dioxide Detection Manual" on the "Quantitative Detection" interface of the instrument software. Finally, the detection result is directly read out on the detection interface.

Embodiment 3

[0061] Example 3 Utilize the PCS Multifunctional Food Safety Rapid Detector to detect the sulfur dioxide content in vermicelli: Weigh 1.5g vermicelli, cut it into pieces, add 25mL of water to shake and extract (or ultrasonically extract) for 15min, if the upper layer solution is not clear, add solution A and solution B Each solution was 1mL, then dilute to 30mL with water, shake, and stand for 5min. If necessary, take 20mL of the supernatant and add 0.2g of activated carbon for decolorization, shake for 2min, and filter for later use.

[0062]Turn on the machine, enter the main detection interface of the PCS multi-function food safety rapid detector, click the "food quality analysis" module, enter the "quantitative detection" interface, set the "test item" to sulfur dioxide, and the "product type" to white sugar. Then follow the steps of the "Sulfur Dioxide Detection Manual" on the "Quantitative Detection" interface of the instrument software. Finally, the detection result is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com