Solar cell string and solar cell component for ground power generation and solar cell plate thereof

A technology of solar cells and solar cells, which is applied in the direction of generators/motors, photovoltaic power generation, electrical components, etc., can solve problems such as power loss of cell components, difficulty in installing cell components, and small light-receiving area of cells. The effect of reducing production costs, reducing power loss, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

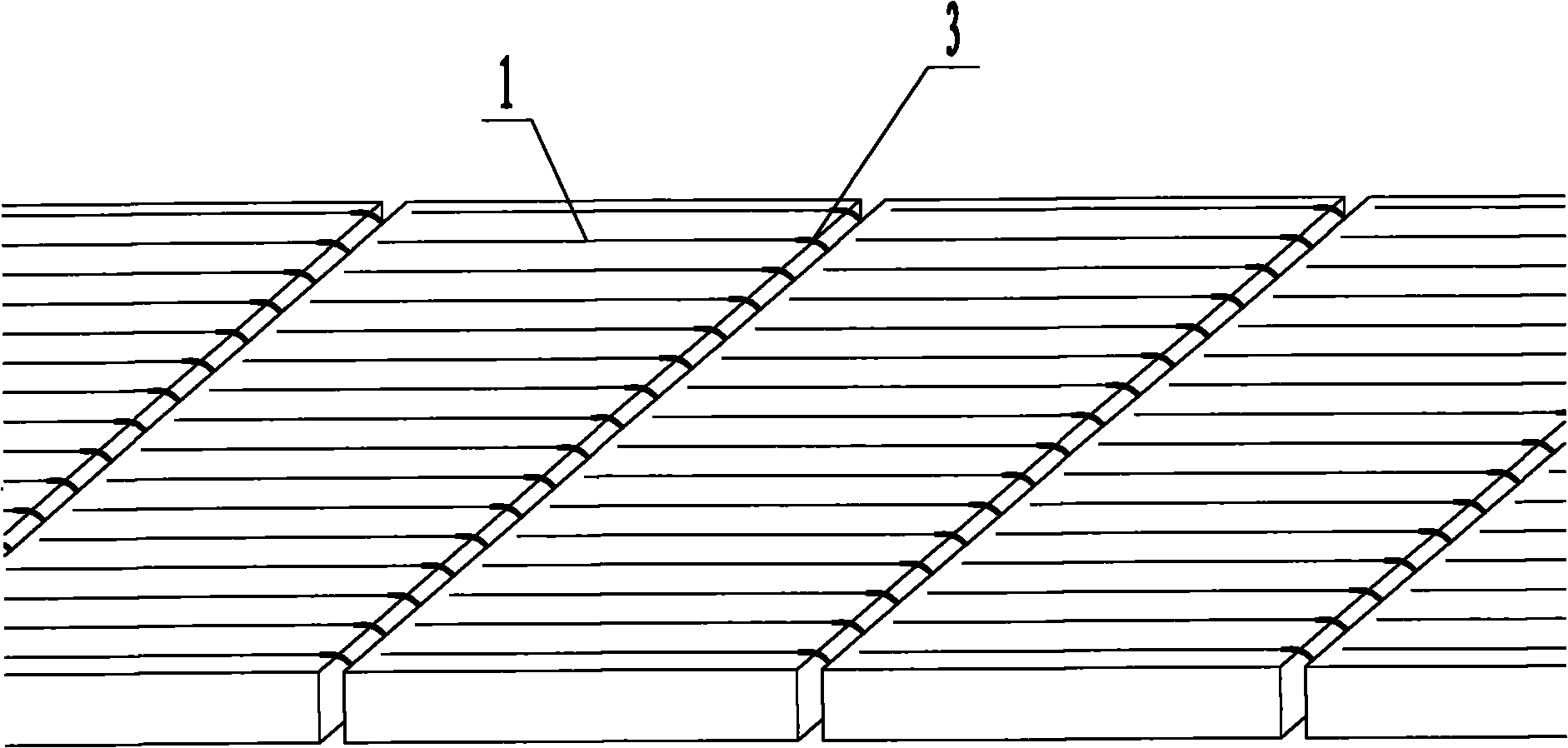

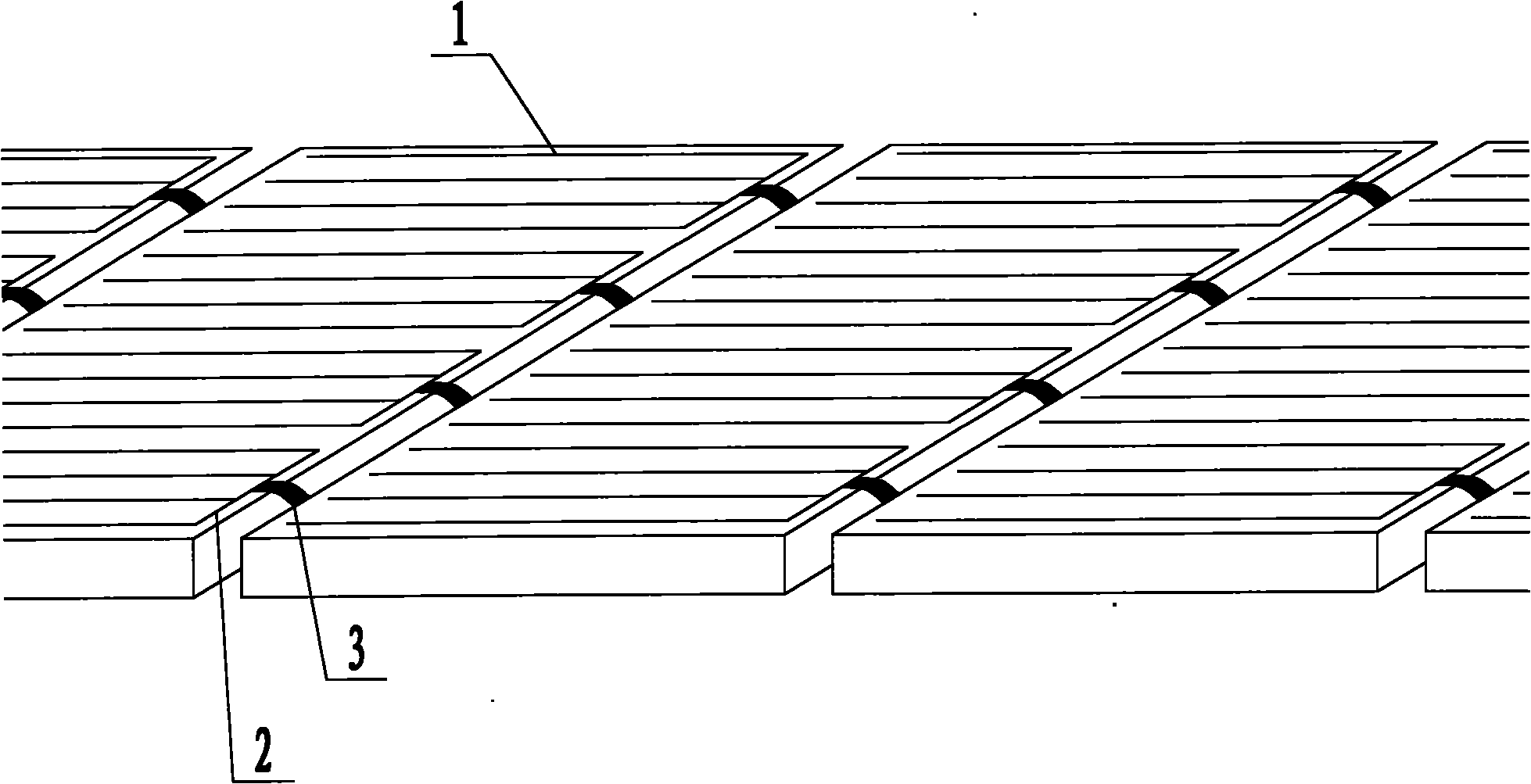

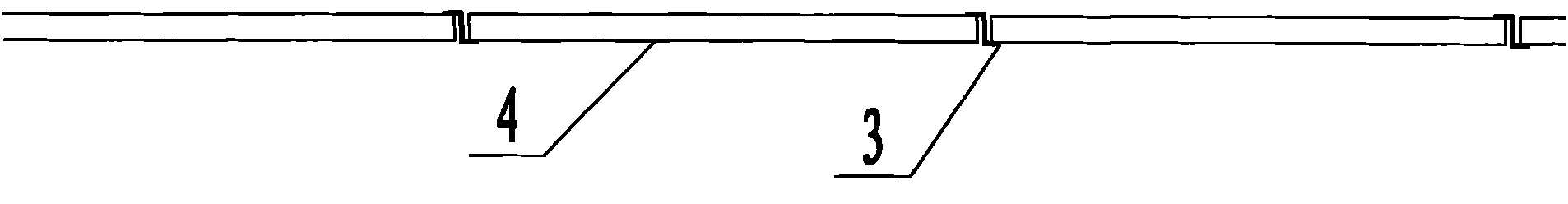

[0047] Embodiment 1. A solar cell string for ground power generation, wherein: the battery sheet has a specification of 3 cm in length, 1 cm in width, and 0.08 mm in thickness. Micron, the interval of the fine grid 1 is 1mm, one end of the battery fine grid 1 is connected to the back of the battery with the same structure by welding with the bus strip 3, and the direction of the bus belt 3 is the same as the direction of the battery fine grid 1.

Embodiment 2

[0048] Embodiment 2, a solar cell string for ground power generation, wherein: the specification of the battery sheet is 5 cm in length, 3 cm in width, and 0.2 mm in thickness, and there is a thin grid 1 on the front of the battery sheet, and the line width of the thin grid 1 is 30 Micron, the interval of the fine grid 1 is 5mm, one end of the cell fine grid 1 is connected to the back of the cell with the same structure by welding with the bus strip 3, and the direction of the bus strip 3 is the same as the direction of the battery fine grid 1.

Embodiment 3

[0049] Embodiment 3, a solar battery string for ground power generation, wherein: the specification of the battery sheet is 10 cm in length, 6 cm in width, and 0.5 mm in thickness, and there is a fine grid 1 on the front of the battery sheet, and the line width of the thin grid 1 is 50 cm. Micron, the interval of the fine grid 1 is 3mm, one end of the cell fine grid 1 is connected to the back of the cell with the same structure by welding with the bus strip 3, and the direction of the bus strip 3 is the same as the direction of the battery fine grid 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com