Method for preparing silicon-aluminium denitrfying agent

A silicon-aluminum denitrification agent and silicon raw material technology, which is applied in the field of purification, can solve the problems of insufficient concentration of the pore size distribution of the silicon-alumina denitrification agent and the reduction of sol generation rate, and achieve the effect of easy regeneration and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

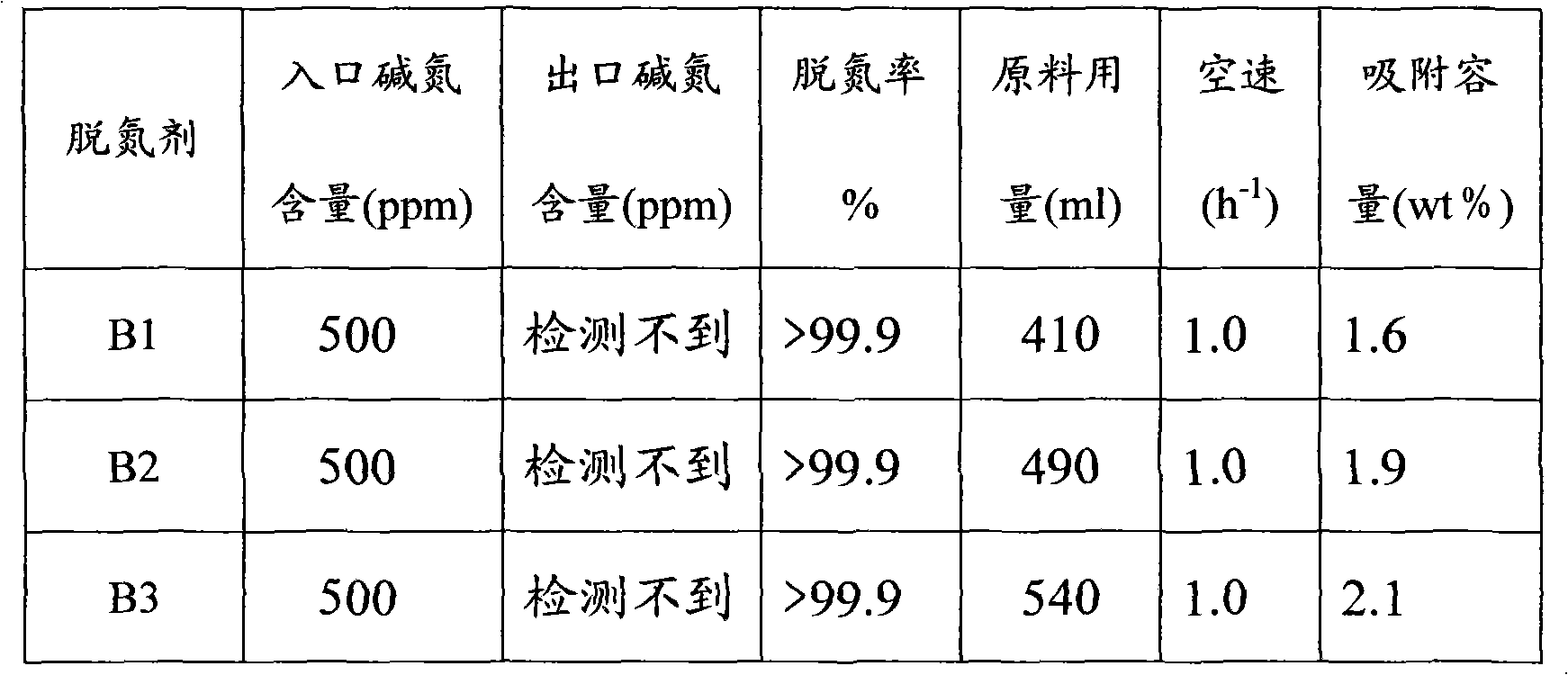

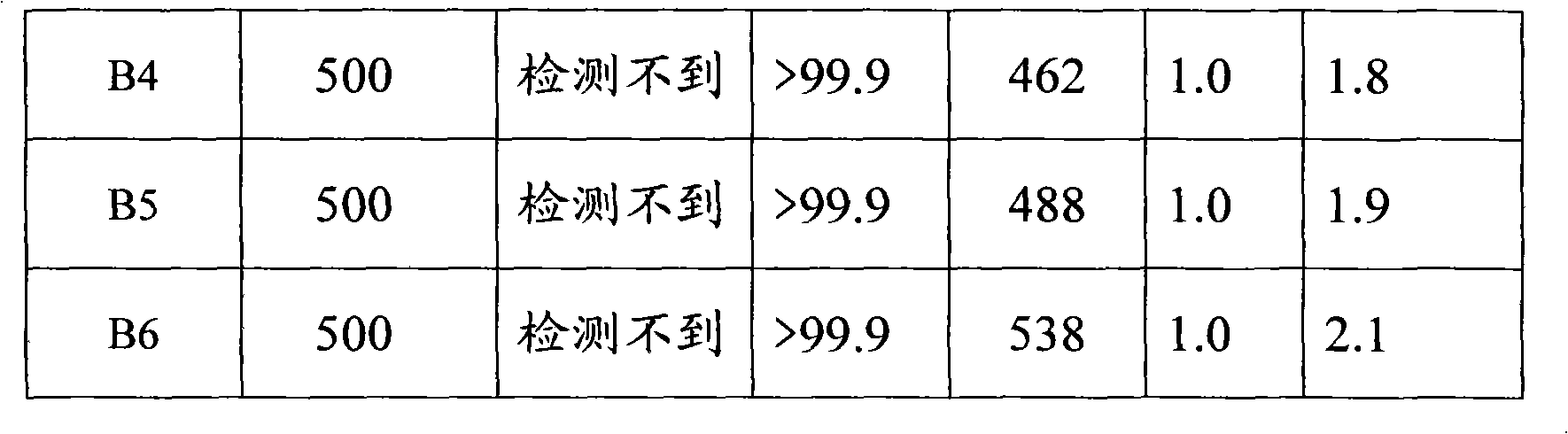

Embodiment 1

[0022] Weigh 20.0g of aluminum isopropoxide and add it to 200g of water, heat to 83°C for 0.5 hour for hydrolysis, then use 1.9g of nitric acid for degumming, hydrolyze for 3 hours at 90°C, and produce product W1 after cooling.

[0023]Weigh 138.7g of tetraethyl orthosilicate, add 80.0g of absolute ethanol, stir for 10 minutes, then add 150.0g of ethanol and water mixed solution with a volume ratio of 1:1, adjust the pH value of the above solution to 3 with nitric acid, Stirring for 1 hour yielded product W2.

[0024] The product W1 and the product W2 were mixed and stirred, and the pH value of the above mixed sol was adjusted to 5.9 with 25% ammonia water to obtain the product W3, and the above product W3 was aged at 50°C for 1d; The product was dried under reduced pressure at 30° C. for 3 days, and baked at 500° C. for 5 hours after molding to obtain denitrification agent product B1 with an alumina content of 10 wt % and a silica content of 90 wt %.

[0025] The test shows ...

Embodiment 2

[0027] Weigh 40g of aluminum isopropoxide and add it to 400g of water, heat to 85°C for 1.0 hour for hydrolysis, then use 3.8g of nitric acid for degumming, hydrolyze for 2.5 hours at 91°C, and produce product W1 after cooling.

[0028] Weigh 142.85g of tetraethyl orthosilicate, add 85.0g of absolute ethanol, stir for 10 minutes, then add 158.0g of ethanol and water mixed solution with a volume ratio of 1:1, adjust the pH value of the above solution to 3 with nitric acid, Stirring for 1 hour yielded product W2.

[0029] The product W1 and the product W2 were mixed and stirred, and the pH value of the above mixed sol was adjusted to 6.1 with 20% ammonia water to obtain the product W3, and the above product W3 was aged at 55 ° C for 2 days; the above-mentioned aged The product was dried under reduced pressure at 40° C. for 2 days, and baked at 550° C. for 4 hours after molding to obtain denitrification agent product B2 with an alumina content of 19.5 wt % and a silica content of...

Embodiment 3

[0032] Weigh 68.7g of aluminum isopropoxide and add it to 847g of water, heat to 86°C for 1.5 hours for hydrolysis, then use 5.7g of nitric acid for degumming, hydrolyze for 2.0 hours at 93°C, and produce product W1 after cooling.

[0033] Weigh 138.7g of tetraethyl orthosilicate, add 83g of absolute ethanol, stir for 10 minutes, then add 150g of ethanol and water mixed solution with a volume ratio of 1:1, adjust the pH value of the above solution to 3 with nitric acid, stir for 1 hours, the product W2 is formed.

[0034] The product W1 and the product W2 were mixed and stirred, and the pH value of the above mixed sol was adjusted to 6.0 with 15% ammonia water to obtain the product W3, and the above product W3 was aged at 60 ° C for 2 days; the above-mentioned aged The product was dried under reduced pressure at 45° C. for 1 day, and baked at 580° C. for 3.5 hours after molding to obtain denitrification agent B3 with an alumina content of 35 wt % and a silica content of 65 wt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com