Method for preparing dye-sensitized solar cell module

A solar cell and dye sensitization technology, applied in the field of solar cells, can solve the problems of solution corrosion, corrosion of metal grid electrodes, etc., to achieve the effect of improving photoelectric conversion efficiency and ensuring long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

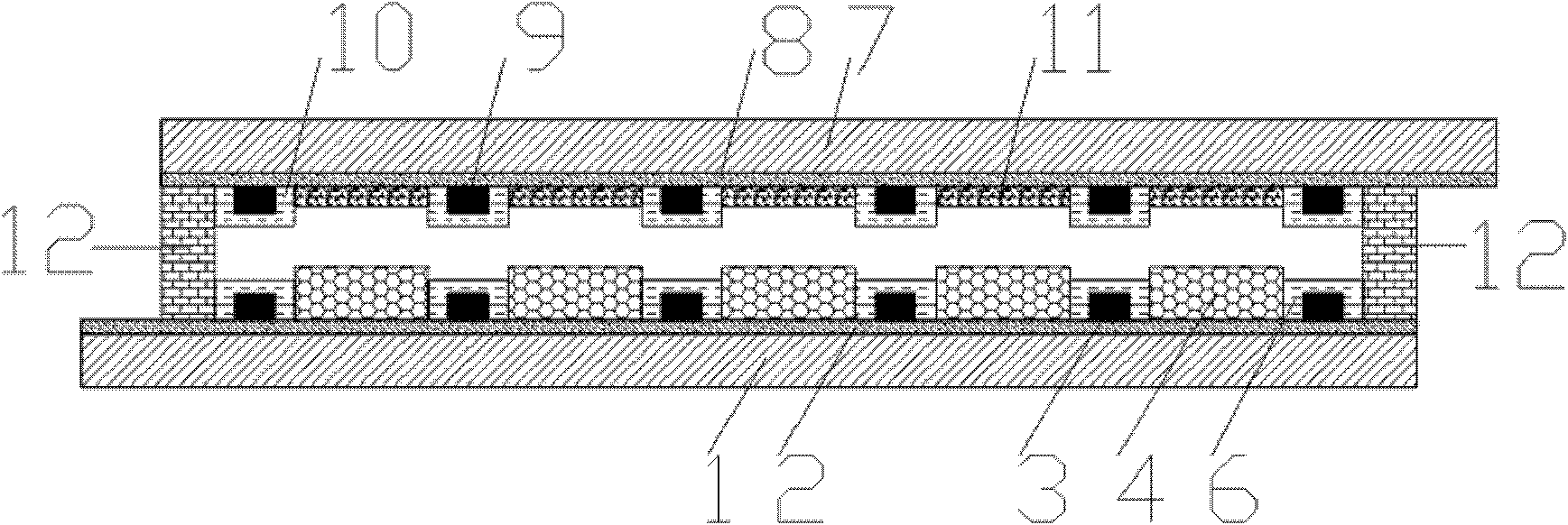

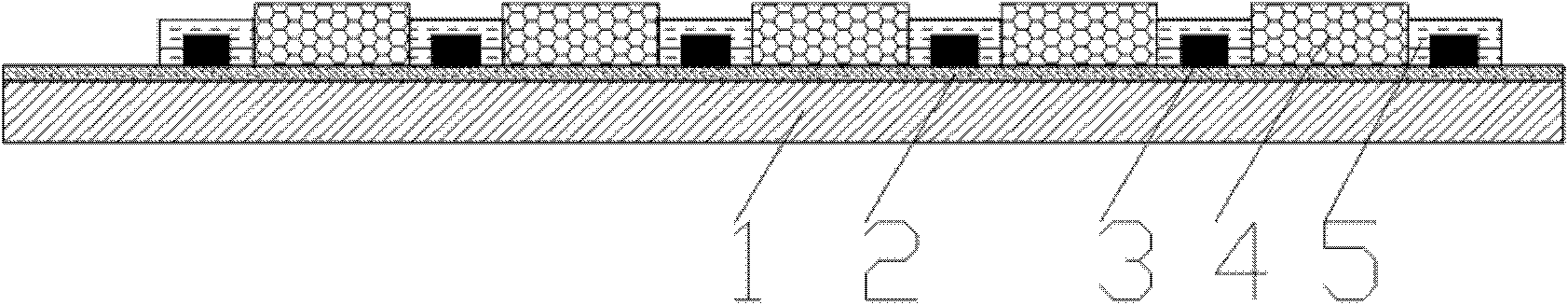

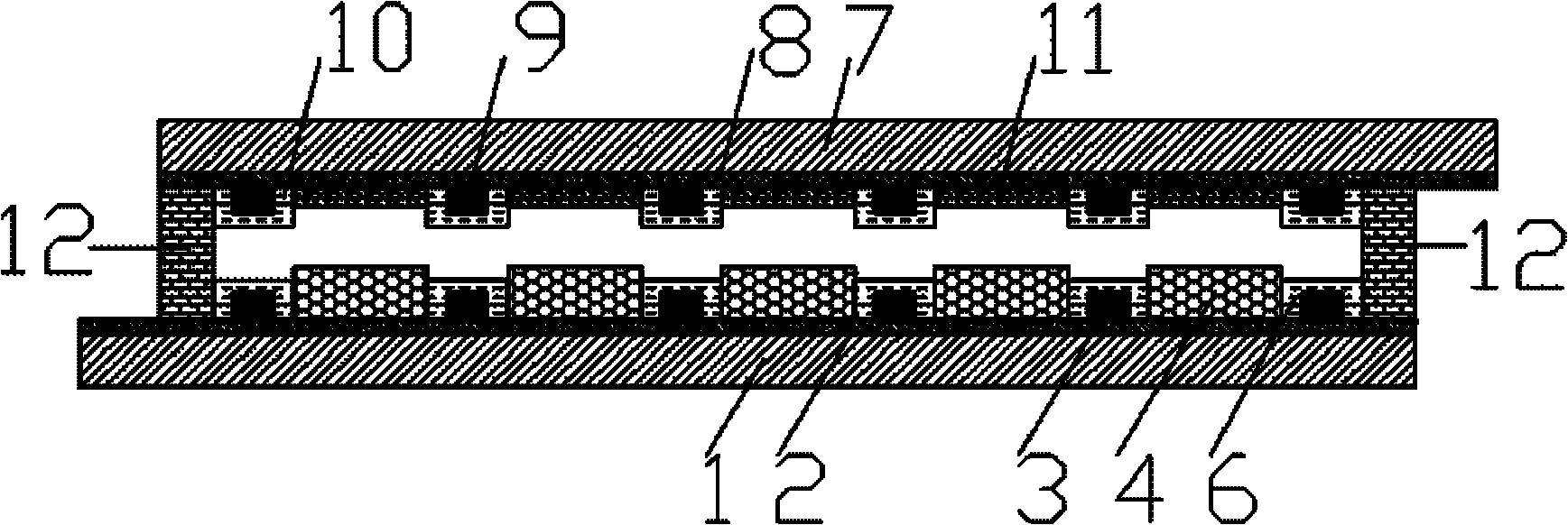

[0012] Embodiment 1 A method for preparing a dye-sensitized solar cell module. The specific preparation method of the cell module is as follows: the conductive glass for the counter electrode is punched into a hole according to the graphic design, and then the conductive glass substrate used for the photoanode and the counter electrode (the photoanode glass substrate 1 comprising the conductive layer 2 and the counter electrode glass substrate 7 comprising the conductive layer 8) carry out ultrasonic cleaning with detergent, acetone, ethanol, and deionized water in sequence, and each cleaning time is 5-20min. After the completion, dry it with an air gun for later use; on the conductive glass substrate of the photoanode and the counter electrode, print a layer of silver grid electrodes 3 and 9 by screen printing according to the designed pattern, and then dry them in an oven at 150° C. for 20 minutes. Then transfer to a resistance furnace for sintering, the sintering temperature...

Embodiment 2

[0015]Example 2 A method for preparing a dye-sensitized solar cell module. The specific preparation method of the cell module is as follows: the conductive glass for the opposite electrode is punched into a hole according to the graphic design, and then the conductive glass substrate used for the photoanode and the opposite electrode (the photoanode glass substrate 1 comprising the conductive layer 2 and the counter electrode glass substrate 7 comprising the conductive layer 8) carry out ultrasonic cleaning with detergent, acetone, ethanol, and deionized water in sequence, and each cleaning time is 5-20min. After the completion, dry it with an air gun for later use; on the conductive glass substrate of the photoanode and the counter electrode, print a layer of silver grid electrodes 3 and 9 by screen printing according to the designed pattern, then dry them in an oven at 150°C for 15 minutes, and then Transfer to a resistance furnace for sintering, the sintering temperature is ...

Embodiment 3

[0018] Example 3 A preparation method of a dye-sensitized solar cell module. The specific preparation method of the cell module is as follows: the conductive glass for the counter electrode is punched into a hole according to the graphic design, and then the conductive glass substrate used for the photoanode and the counter electrode (the photoanode glass substrate 1 comprising the conductive layer 2 and the counter electrode glass substrate 7 comprising the conductive layer 8) carry out ultrasonic cleaning with detergent, acetone, ethanol, and deionized water in sequence, and each cleaning time is 5-20min. After the completion, dry it with an air gun for later use; on the conductive glass substrate of the photoanode and the counter electrode, print a layer of silver grid electrodes 3 and 9 by screen printing according to the designed pattern, and then dry them in an oven at 150° C. for 20 minutes. Then transfer to a resistance furnace for sintering, the sintering temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com