Solid titanium catalyst ingredient, catalyst for olefin polymerization, and method of polymerizing olefin

A technology for titanium catalyst and olefin polymerization, which is applied in the field of polymerized solid titanium catalyst components and catalysts for olefin polymerization to achieve excellent rigidity and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0255] (Preparation of Solid Titanium Catalyst Component (α1))

[0256] After fully carrying out nitrogen replacement to the high-speed stirring device (manufactured by Special Machine Chemical Industries) with an internal volume of 2 liters, 700 ml of purified decane, 10 g of commercially available magnesium chloride, 24.2 g of ethanol and trade name Rheodol SP-S20 ( 3 g of sorbitan distearate (produced by Kao Co., Ltd.), was heated up while stirring the suspension, and the suspension was stirred at 800 rpm at 120° C. for 30 minutes. Next, the suspension was stirred at a high speed so that no sediment was produced, and at the same time, using a Teflon (registered trademark) tube with an inner diameter of 5 mm, it was transferred to 2 liters of glass containing 1 liter of purified decane cooled to -10° C. in a flask (with a stirrer). The solid formed by pipetting was filtered and washed well with purified n-heptane to obtain a solid adduct in which 2.8 mol of ethanol was coor...

Embodiment 2

[0264] (Preparation of Solid Titanium Catalyst Component (α2))

[0265] In addition to adding 0.13 moles of 3,6-dimethylcyclohexane-1,2-dicarboxylate diisobutyl ester (cis isomer, trans isomer mixture), 0.04 mole of cyclohexane-1 , Except for diisobutyl 2-dicarboxylate (cis isomer, trans isomer mixture), the same procedure as in Example 1 was carried out to obtain a solid titanium catalyst component (α2).

[0266] (official aggregation)

[0267] Propylene was polymerized in the same manner as in Example 1 except that the solid titanium catalyst component (α2) was used instead of the solid titanium catalyst component (α1). The results are shown in Table 1.

Embodiment 3

[0269] (Preparation of Solid Titanium Catalyst Component (α3))

[0270] In addition to adding 0.12 moles of 3,6-dimethylcyclohexane-1,2-dicarboxylate diisobutyl ester (cis isomer, trans isomer mixture), 0.06 mole of cyclohexane-1 , Except for diisobutyl 2-dicarboxylate (cis isomer, trans isomer mixture), the same procedure as in Example 1 was carried out to obtain a solid titanium catalyst component (α3).

[0271] (official aggregation)

[0272] Propylene was polymerized in the same manner as in Example 1 except that the solid titanium catalyst component (α3) was used. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

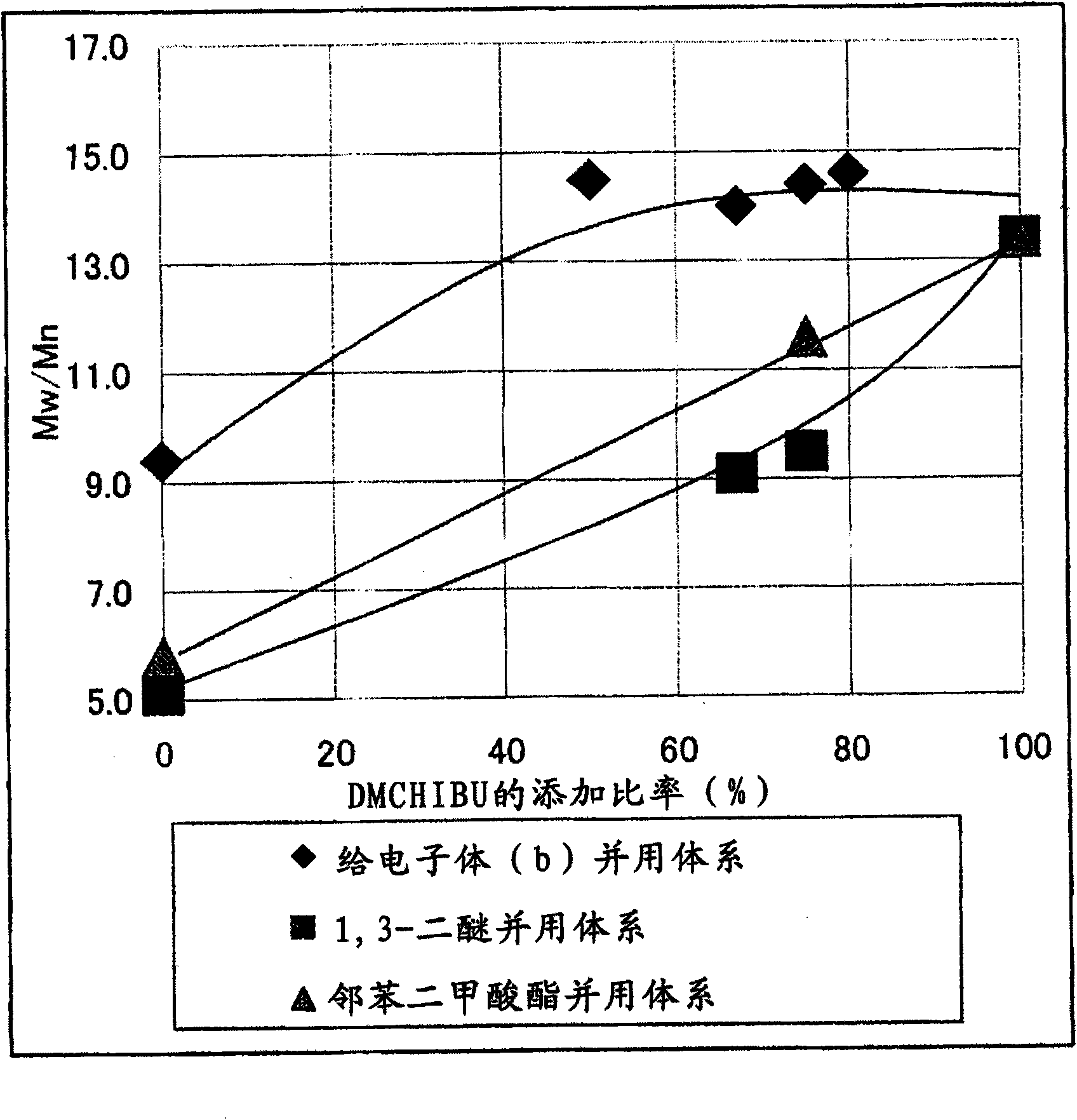

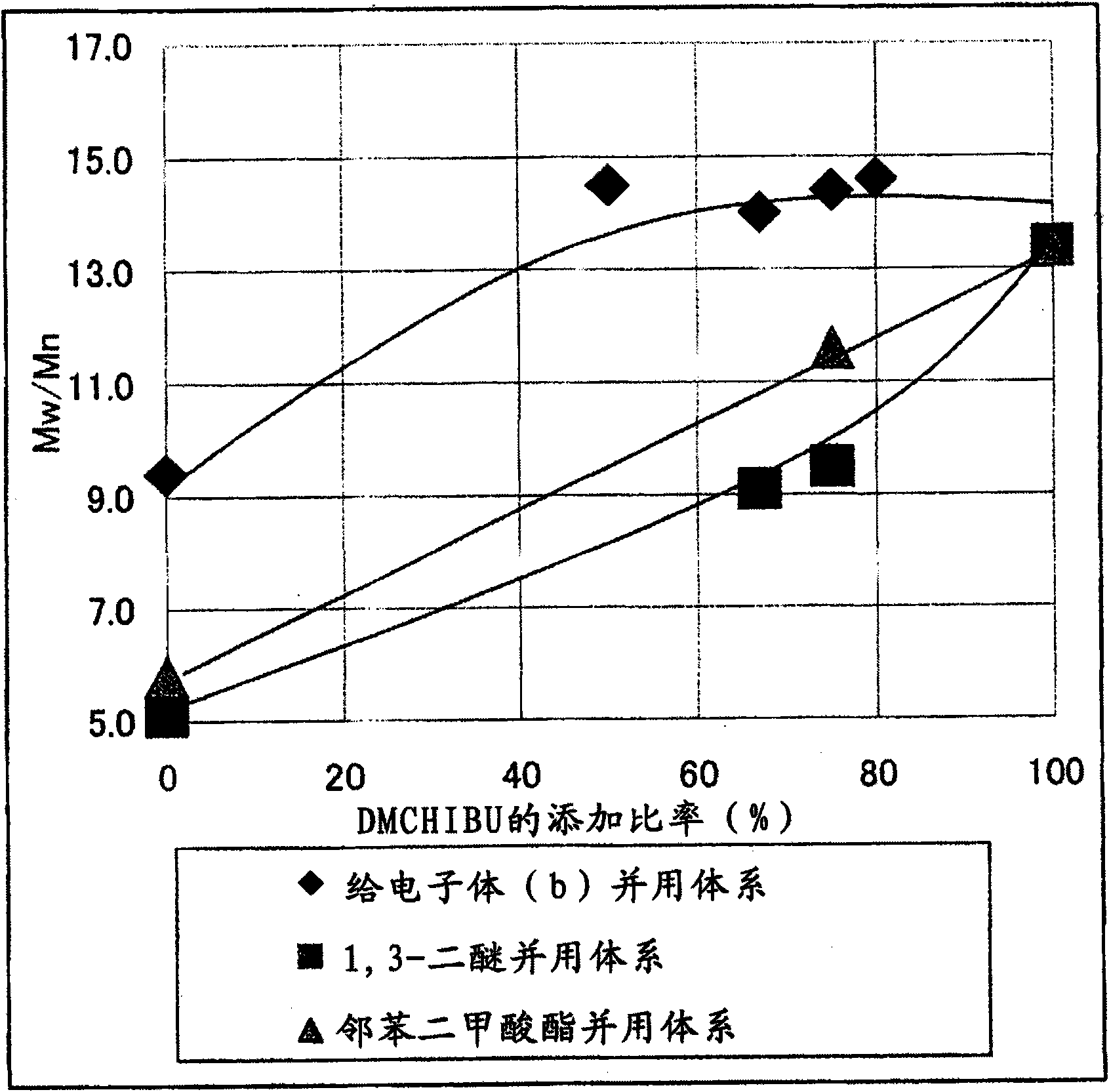

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com