Method for modifying surface of cotton fabric by adopting titanium sulfate and urea

A technology of cotton fabric and titanium sulfate, which is applied to the surface modification of cotton fabric. The surface modification of cotton fabric with titanium sulfate and urea can solve the problems of poor washing resistance, poor air permeability, and bad hand feeling. Excellent washing resistance, easy operation, and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

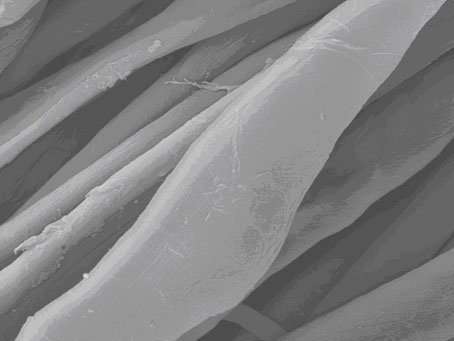

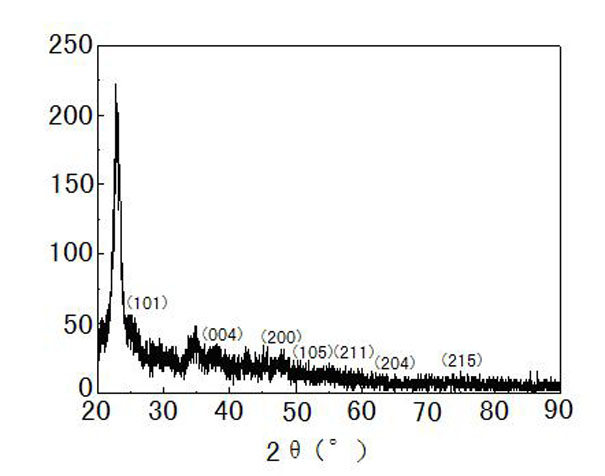

[0028] Weigh 14.4g of cotton fabric, 9.6g of titanium sulfate and 24g of urea respectively. Cotton fabrics were washed with a solution of deionized water and absolute ethanol at a volume ratio of 1:1 at a temperature of 80 ° C for 30 min with ultrasonic vibration at 50 KHz and a power of 100 W, and then dried at 60 ° C. Dissolve titanium sulfate in 300ml of deionized water, add urea and stir vigorously, then add cotton fabric and soak for 10 minutes; put the soaked cotton fabric together with titanium sulfate urea solution into a 500ml high temperature and high pressure reactor, and fill it with deionized water To 80% of the volume of the reactor, the sealed reactor was kept at 130°C for 1.5 hours at a constant temperature. Finally, after the reaction is over, use 2g / L soap flakes, 2g / L soda ash, and a bath ratio of 1:30 to treat the cotton fabric at 90°C for 15 minutes, then wash it repeatedly with 90°C hot water and cold water, and dry it at 60°C. Dry. Figure 4 It is the ...

Embodiment 2

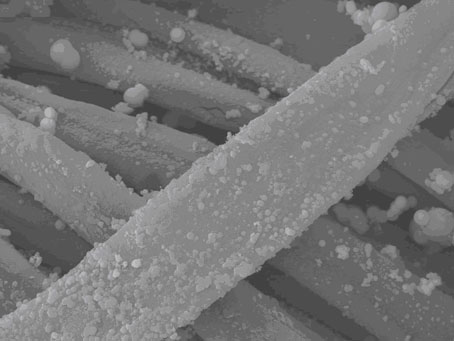

[0031] Weigh 14.4g of cotton fabric, 48g of titanium sulfate and 24g of urea respectively. Cotton fabrics were washed with a solution of deionized water and absolute ethanol at a volume ratio of 1:1 at a temperature of 80 ° C for 30 min with ultrasonic vibration at 50 KHz and a power of 100 W, and then dried at 60 ° C. Dissolve titanium sulfate in 300ml of deionized water, add urea and stir vigorously, then add cotton fabric and soak for 40 minutes; put the soaked cotton fabric together with titanium sulfate solution into a 500ml high-temperature and high-pressure reactor, and fill it with deionized water to 80% of the volume of the reactor, the sealed reactor was treated at 160°C for 3 hours. Finally, after the reaction is over, use 2g / L soap flakes, 2g / L soda ash, and a bath ratio of 1:30 to treat the cotton fabric at 90°C for 15 minutes, then wash it repeatedly with 90°C hot water and cold water, and dry it at 60°C. Dry. Figure 5 It is the ultraviolet reflection spectrum...

Embodiment 3

[0034] Weigh 14.4g of cotton fabric, 24g of titanium sulfate and 24g of urea respectively. Cotton fabrics were washed with a solution of deionized water and absolute ethanol at a volume ratio of 1:1 at a temperature of 80 ° C for 30 min with ultrasonic vibration at 50 KHz and a power of 100 W, and then dried at 60 ° C. Dissolve titanium sulfate in 300ml of deionized water, add urea and stir vigorously, then add cotton fabric and soak for 40 minutes; put the soaked cotton fabric together with titanium sulfate solution into a 500ml high-temperature and high-pressure reactor, and fill it with deionized water to 80% of the volume of the reactor, the sealed reactor was treated at 140°C for 2 hours. Finally, after the reaction is over, use 2g / L soap flakes, 2g / L soda ash, and a bath ratio of 1:30 to treat the cotton fabric at 90°C for 15 minutes, then wash it repeatedly with 90°C hot water and cold water, and dry it at 60°C. Dry. Image 6 It is the ultraviolet reflection spectrum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com