Fluorescent polymer environment-friendly material with Beta-dione aggregative luminous structure

A fluorescent polymer and polymer technology, applied in the direction of luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

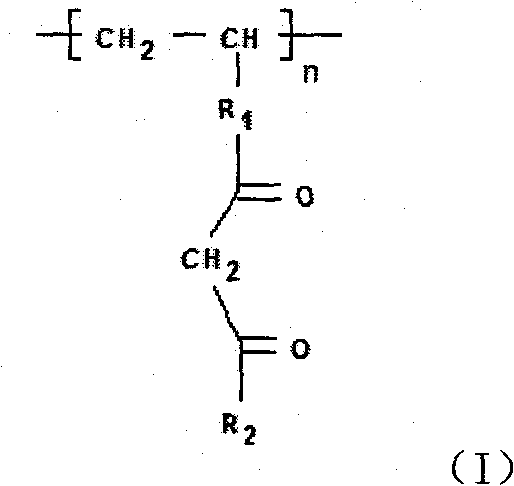

[0047] Embodiment 1: Initiator azobisisobutyronitrile AIBN is used for bulk polymerization to prepare polyacetoacetoxyethyl methacrylate (PAAEMA)

[0048] 0.5% AIBN was dissolved in the monomer acetoacetoxyethyl methacrylate (AAEMA), and added to a dry three-necked round-bottom flask with a stirrer and a thermometer. Under gentle stirring, blow nitrogen for 10 minutes and heat to 60°C. The monomer is pre-polymerized into a liquid with a higher viscosity, and it is poured into the mold. After sufficient degassing, the prepolymer was allowed to continue polymerizing at 50°C. Finally, at 105°C, heating was continued for 2 hours to complete the polymerization reaction.

Embodiment 2

[0049] Embodiment 2: Initiator AIBN is used for bulk polymerization to prepare polyethylene ethyl acryloyl acetate

[0050] 0.5% AIBN was dissolved in the monomer ethyl allyl acetate (EAA), and added to a dry three-necked round-bottom flask with a stirrer and a thermometer. Under gentle stirring, blow nitrogen for 10 minutes and heat to 60°C. The monomer is pre-polymerized into a liquid with a higher viscosity, and it is poured into the mold. After sufficient degassing, the prepolymer was allowed to continue polymerizing at 50°C. Finally, at 105°C, heating was continued for 2 hours to complete the polymerization reaction.

Embodiment 3

[0051] Embodiment 3: Initiator AIBN is used for bulk polymerization to prepare polyacryloyl ethyl ketone

[0052] 0.5% AIBN was dissolved in monomer propionylacetone (AA), and added into a dry three-necked round-bottomed flask equipped with a stirrer and a thermometer. Under gentle stirring, blow nitrogen for 10 minutes and heat to 60°C. The monomer is pre-polymerized into a liquid with a higher viscosity, and it is poured into the mold. After sufficient degassing, the prepolymer was allowed to continue polymerizing at 50°C. Finally, at 105°C, heating was continued for 2 hours to complete the polymerization reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com