Self-drying aqueous alkyd resin solution and preparation method thereof

A water-based alkyd resin and resin solution technology, which is applied in the field of self-drying water-based alkyd resin solution and its preparation, can solve the problems of water resistance, poor corrosion resistance, slow drying speed of coating film, poor weather resistance, etc., and achieve The effect of easy availability of raw materials, less emissions, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

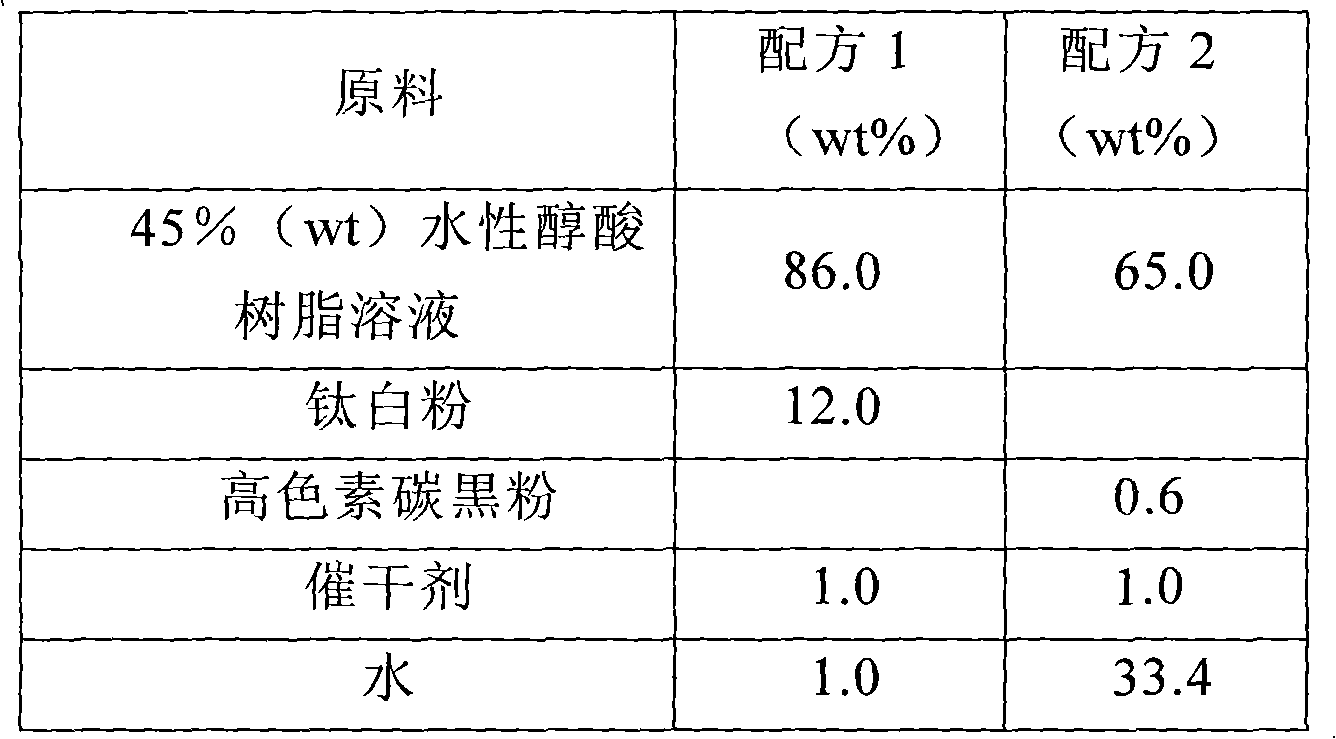

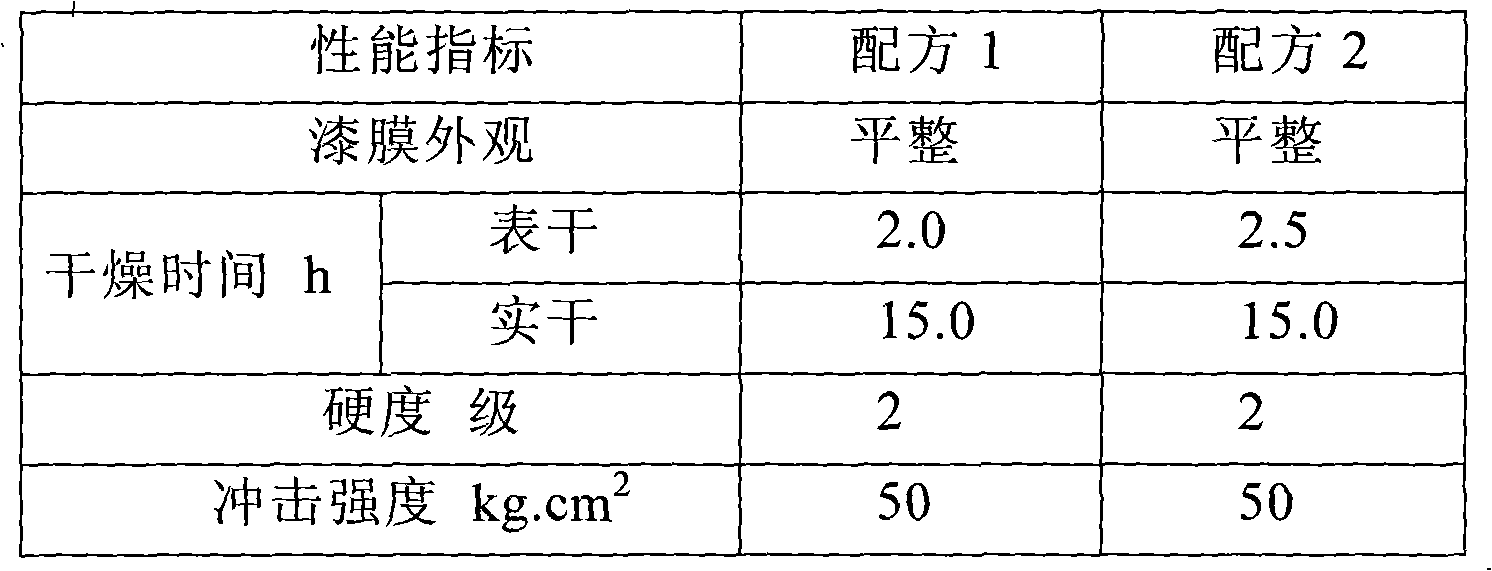

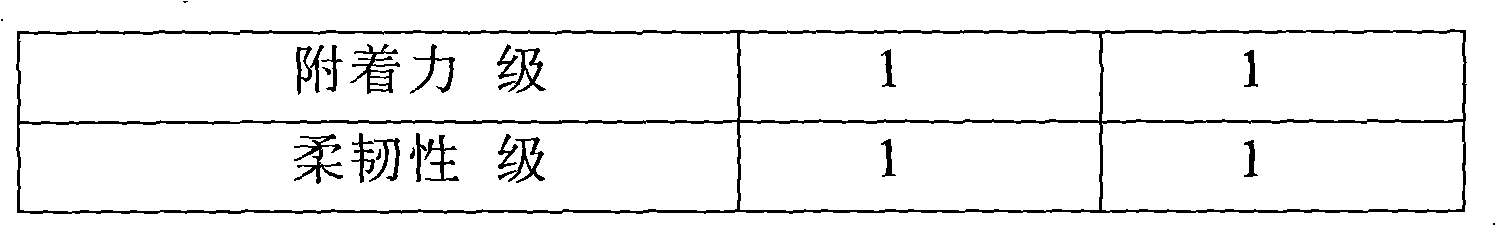

Examples

Embodiment 1

[0030] (1) Add 20kg of terephthalic acid, 5kg of toluic acid, 37kg of triethylene glycol, 45kg of rosin, and 0.2kg of color reducing agent into the reaction kettle to raise the temperature. When the solid reactant melts, start stirring, keep warm at 220°C for 2h, and then Gradually raise the temperature to 260°C, and distill off the esterified water during the reaction to obtain a resin solution;

[0031] (2) When the acid value of the resin solution drops to 15mgKOH / g, cool the solution to 140°C, add 12kg of maleic anhydride, heat up to 220°C, and keep warm until the acid value of the resin solution is 50mgKOH / g;

[0032] (3) Cool the above solution to 120°C, add 15kg of n-butanol, continue to cool down to 60°C, add ammonia water, adjust the pH value of the solution to 8.0, stir for 0.5h, add 1.4 times the amount of resin in deionized water, and prepare self-drying Type water-based alkyd resin solution, the solid content of the resin solution is 45g / 100g deionized water, the ...

Embodiment 2

[0034] (1) Add 21kg of terephthalic acid, 15kg of benzoic acid, 38kg of propylene glycol, 25kg of rosin, and 0.2kg of color reducing agent into the reactor to raise the temperature. When the solid reactant melts, start stirring, keep the temperature at 220°C for 2h, and then gradually raise the temperature to 250°C ℃, the esterification water was distilled off during the reaction to obtain a resin solution;

[0035] (2) When the acid value of the resin solution drops to 20mgKOH / g, cool the solution to 140°C, add 12kg of maleic anhydride, heat up to 220°C, and keep warm until the acid value of the resin solution is 60mgKOH / g;

[0036] (3) Cool the above solution to 120°C, add 15kg of ethylene glycol ether, continue to cool down to 60°C, add triethylamine, adjust the pH value of the solution to 8.0, stir for 0.5h, add deionized water 1.4 times the amount of resin, and prepare Obtained from dry water-based alkyd resin solution, the solid content of the resin solution is 45g / 100g ...

Embodiment 3

[0038] (1) Add 21kg of terephthalic acid, 32kg of benzoic acid, 32kg of propylene glycol, 10kg of rosin, and 0.2kg of color reducing agent into the reactor to raise the temperature. When the solid reactant melts, start stirring, keep the temperature at 220°C for 2h, and then gradually raise the temperature to 250°C ℃, the esterification water was distilled off during the reaction to obtain a resin solution;

[0039] (2) When the acid value of the resin solution drops to 20mgKOH / g, cool the solution to 140°C, add 12kg of maleic anhydride, heat up to 220°C, and keep warm until the acid value of the resin solution is 40mgKOH / g;

[0040] (3) Cool the above solution to 120°C, add 15kg of ethylene glycol methyl ether, continue to cool down to 60°C, add triethylamine, adjust the pH value of the solution to 8.0, stir for 0.5h, add deionized water with 1.4 times the amount of resin, Prepare self-drying water-based alkyd resin solution, the solid content of the resin solution is 45g / 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com