Nano ZnO/SiO2 sol modified self-cleaning silicone-acrylic exterior wall insulating mould coating

A silicone-acrylic exterior wall and thermal insulation coating technology, applied in the direction of reflection/signal coatings, coatings, etc., to achieve excellent adaptability, excellent thermal insulation effect, and the effect of reducing heat energy transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of nano ZnO / SiO2 sol-modified silicon acrylic exterior wall self-cleaning heat-insulating coating, comprising the following steps (wherein each percentage is a percentage by weight):

[0021] 1. Put 40% fluorine-modified silicon-acrylic emulsion into the material tank first, and dope 8% nano-Sb with SnO 2 , nano ZnO sol and nano SiO 2 4% of the sol and 2% of the silane-based molecular bridge were added sequentially and then dispersed at a speed of 1200 rpm, and ultrasonic waves were introduced to assisted dispersion for 40 minutes to generate a base material liquid.

[0022] 2. Add 12% hollow ceramic microspheres, 13% titanium dioxide, and 0.2% defoamer, 0.1% bactericide, 0.5% thickener, 0.45% film-forming aid, and 6% rheological agent to the base in sequence In the feed liquid, finally add deionized water and stir for 40 minutes at a speed of 1200 rpm to mix evenly, and adjust the viscosity to 80KU (both thickener and rheological agent can adjust ...

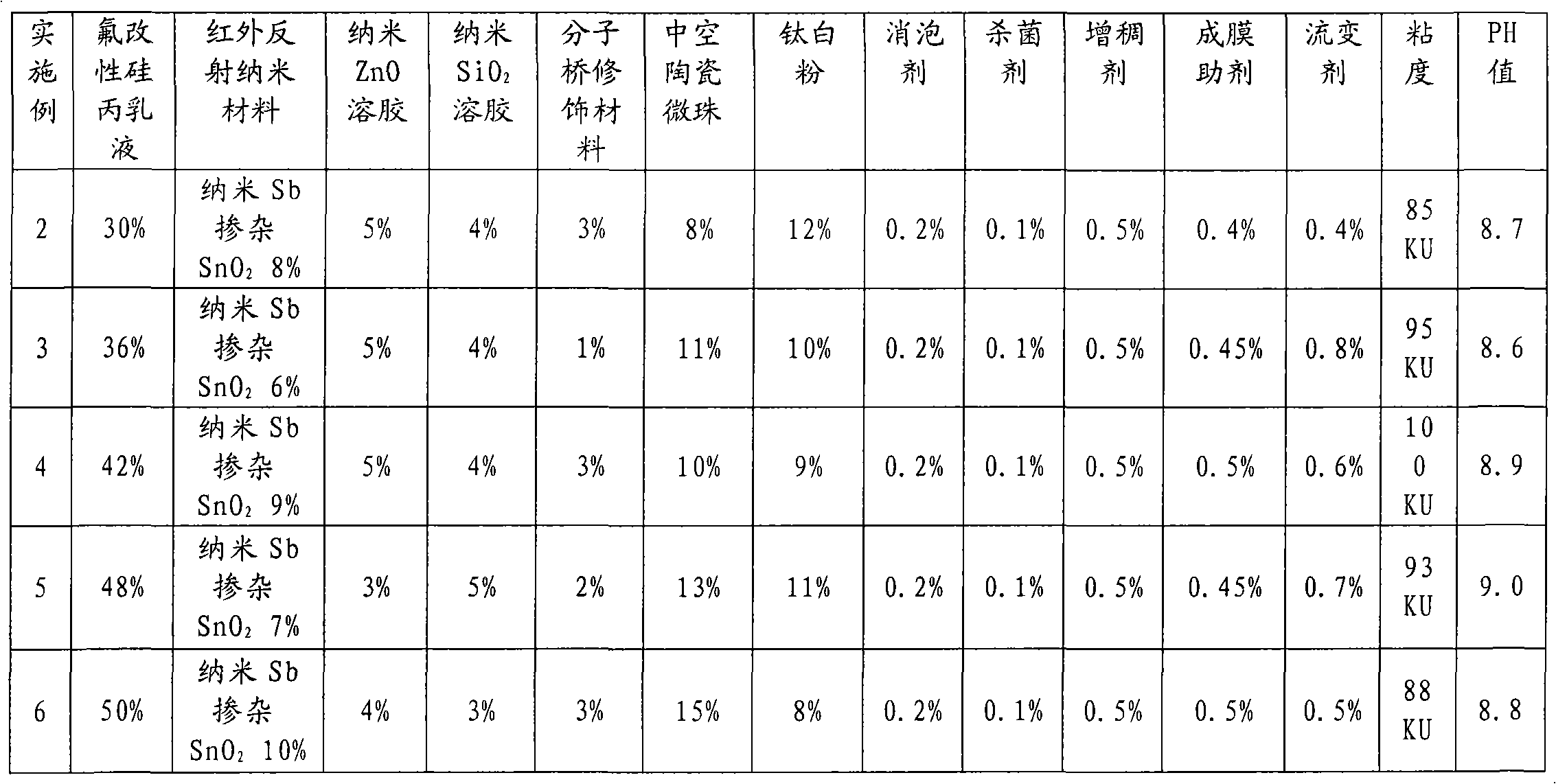

Embodiment 2~6

[0024] Using the raw materials in the following table and their weight ratio relationship and adjustment parameters, and using the same preparation method as in Example 1, the nano ZnO / SiO2 sol-modified silicon acrylic exterior wall self-cleaning heat-insulating coating of the present invention was prepared:

[0025]

[0026] The above-mentioned infrared reflective nanomaterial is nano-Sb, or nano-Sb doped SnO 2 , or prior art infrared reflective nanomaterials.

[0027] The above molecular bridge modification materials are silane molecular bridges, or other existing molecular bridge modification materials.

[0028] The above-mentioned conventional auxiliary materials such as defoamers, bactericides, thickeners, film-forming aids, and rheological agents are commonly used constituents in the field of coatings. As prior art, no further description will be made.

[0029] Using the present invention as an exterior wall coating, after testing, the prepared coating has a sunlight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com