Integral electroforming method and dedicated die of three-dimensional sculpture

A three-dimensional, electroforming technology, applied in electroforming and electrolysis processes, etc., can solve the problems of time-consuming, labor-intensive, easy to produce deformation, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

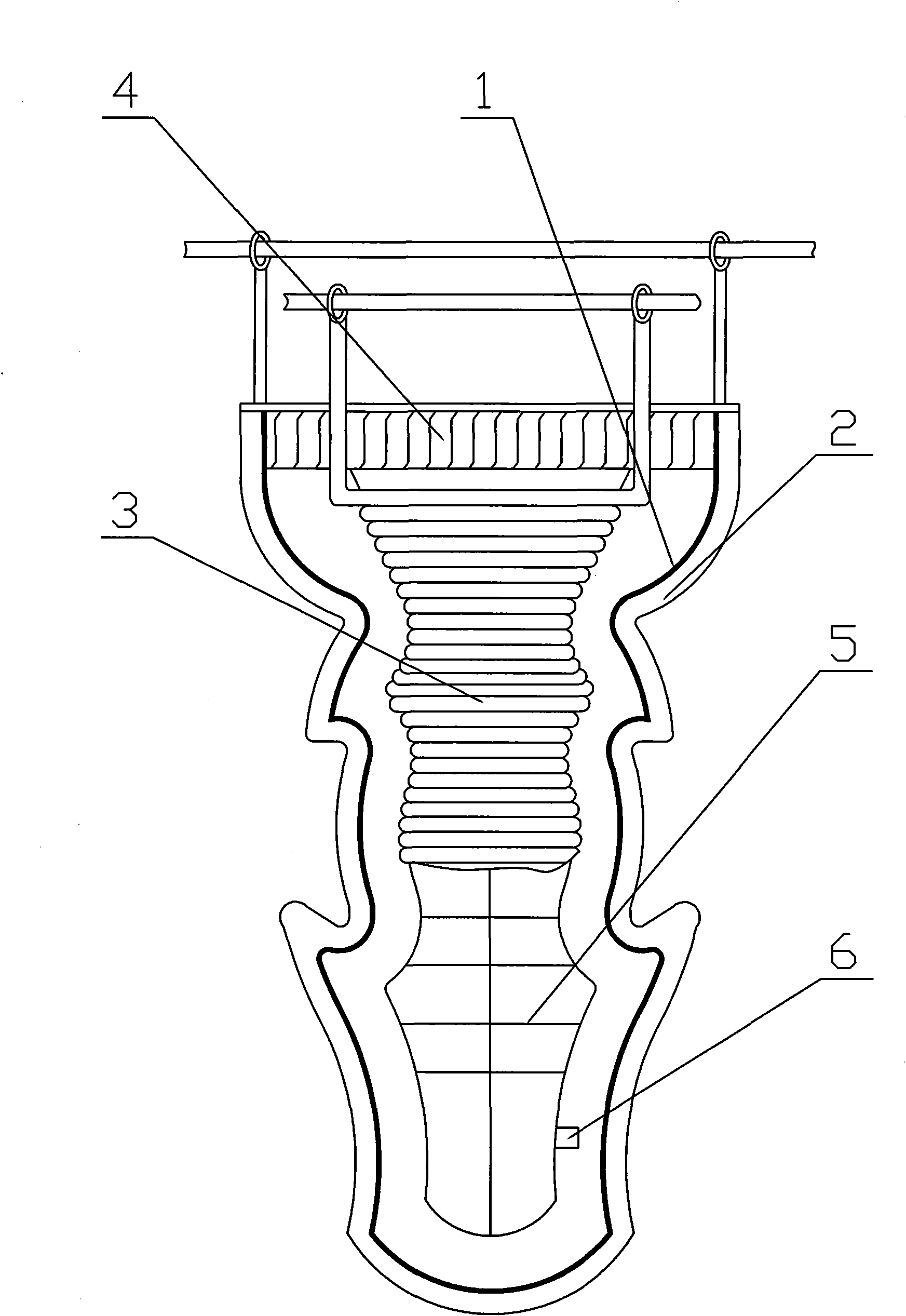

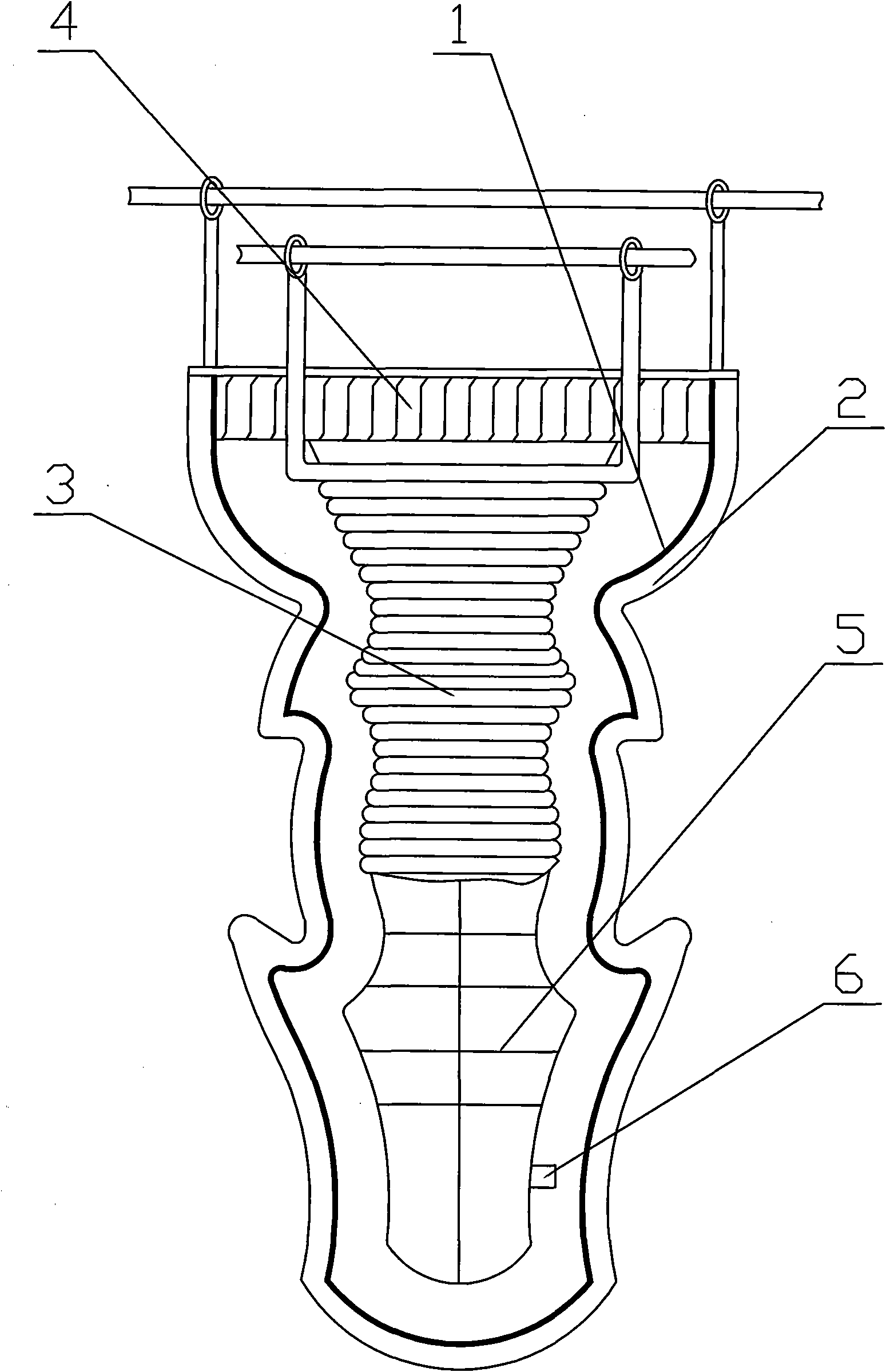

[0023] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. The special mold of the present invention such as figure 1 As shown: there is a three-dimensional hollow female mold 2 made of insulating materials such as silica gel or gypsum, the upper part is open, and the inner wall is coated with a conductive layer 1. A conductive electrode 4 connected to the conductive layer 1 is provided at the opening of the female mold 2; At the same time, a three-dimensional conformal anode 3 that can be placed in the inner cavity of the female mold 2 is provided. The three-dimensional conformal anode 3 is a three-dimensional shape, and the distance between its outer surface and the conductive layer 1 is 1 to 7 cm, that is, as long as the three-dimensional conformal anode 3 The shortest distance between each point on the outer surface and the conductive layer 1 can be in the range of 1-7 cm, which can be the same or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com