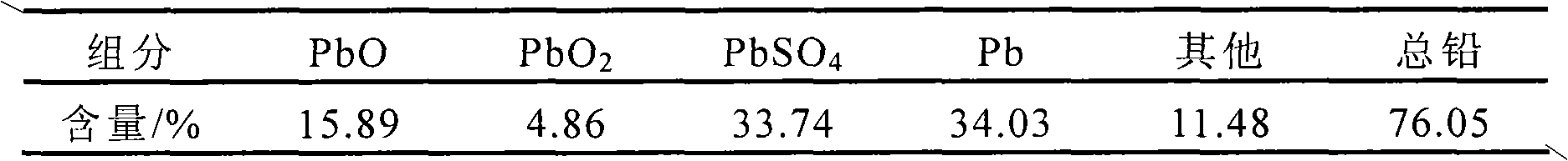

Method for preparing lead chloride and calcium sulfate from lead plasters of waste lead accumulators by wet process

A waste lead storage battery, calcium sulfate technology, applied in the direction of lead halide, calcium/strontium/barium sulfate, etc., can solve the problems of waste of resources, inability to precipitate lead chloride, lead pollution, etc., to achieve effective recycling and improve recovery rate , avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the present embodiment carries out as follows:

[0027] 1. In the lead plaster with a particle size of 74 μm, add saturated sodium chloride solution according to the weight ratio of lead plaster to saturated sodium chloride solution at 1:13, and add the weight percentage concentration of 1:2.5 according to the weight ratio of lead plaster to it 37% hydrochloric acid was reacted at 75° C. for 170 minutes. After the reaction was completed, the filter cake and filtrate were filtered while hot, and the lead leaching rate was 99.2%.

[0028] 2. Lower the above-mentioned lead paste leaching filtrate to room temperature, and let it stand at room temperature for 3.5 hours, let the lead chloride in it crystallize and precipitate, and filter; the filter cake is washed and dried at 105°C for 1.5 hours to obtain the lead chloride product . The content of lead chloride in this product is 99.6%, which has reached the requirement of the quality standard.

[0029] 3. Ad...

Embodiment 2

[0030] Embodiment 2: the present embodiment carries out as follows:

[0031] 1. In the lead plaster with a particle size of 74 μm, add saturated sodium chloride solution according to the weight ratio of lead plaster to saturated sodium chloride solution as 1:14, and add the weight percentage concentration of 1:2.2 according to the weight ratio of lead paste to it. 37% hydrochloric acid was reacted at 95° C. for 150 minutes. After the reaction was completed, the filter cake and filtrate were filtered while hot, and the lead leaching rate was 99.5%.

[0032] 2. Lower the filtrate from the above-mentioned lead paste to room temperature, and let it stand at room temperature for 4 hours to allow the lead chloride in it to crystallize and precipitate, and filter; the filter cake is washed and dried at 101°C for 2 hours to obtain the lead chloride product. The content of lead chloride in this product is 99.4%, which has reached the requirement of the quality standard.

[0033] 3. Ad...

Embodiment 3

[0034] Embodiment 3: the present embodiment carries out as follows:

[0035] 1. In the lead plaster with a particle size of 74 μm, add saturated sodium chloride solution according to the weight ratio of lead plaster to saturated sodium chloride solution at 1:15, and add the weight percent concentration of 37% hydrochloric acid was reacted at 85° C. for 160 minutes. After the reaction was completed, the filter cake and filtrate were filtered while hot, and the lead leaching rate was 99.7%.

[0036] 2. Lower the above-mentioned lead paste leaching filtrate to room temperature, and let it stand at room temperature for 4.5 hours, let the lead chloride in it crystallize and precipitate, and filter; the filter cake is washed and dried at 108°C for 1 hour to obtain the lead chloride product . The content of lead chloride in this product is 99.2%, which has reached the requirement of the quality standard.

[0037] 3. Add industrial calcium chloride to the above-mentioned cold analys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com