Method for preparing organophosphorus sensitive polymer material by introducing hexafluoroisopropanol functional group into polymer

A hexafluoroisopropanol functional, polymer material technology, applied in the field of gas-sensitive polymer materials, can solve problems such as threats to the life and health of operators, inability to observe the process of the reaction, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

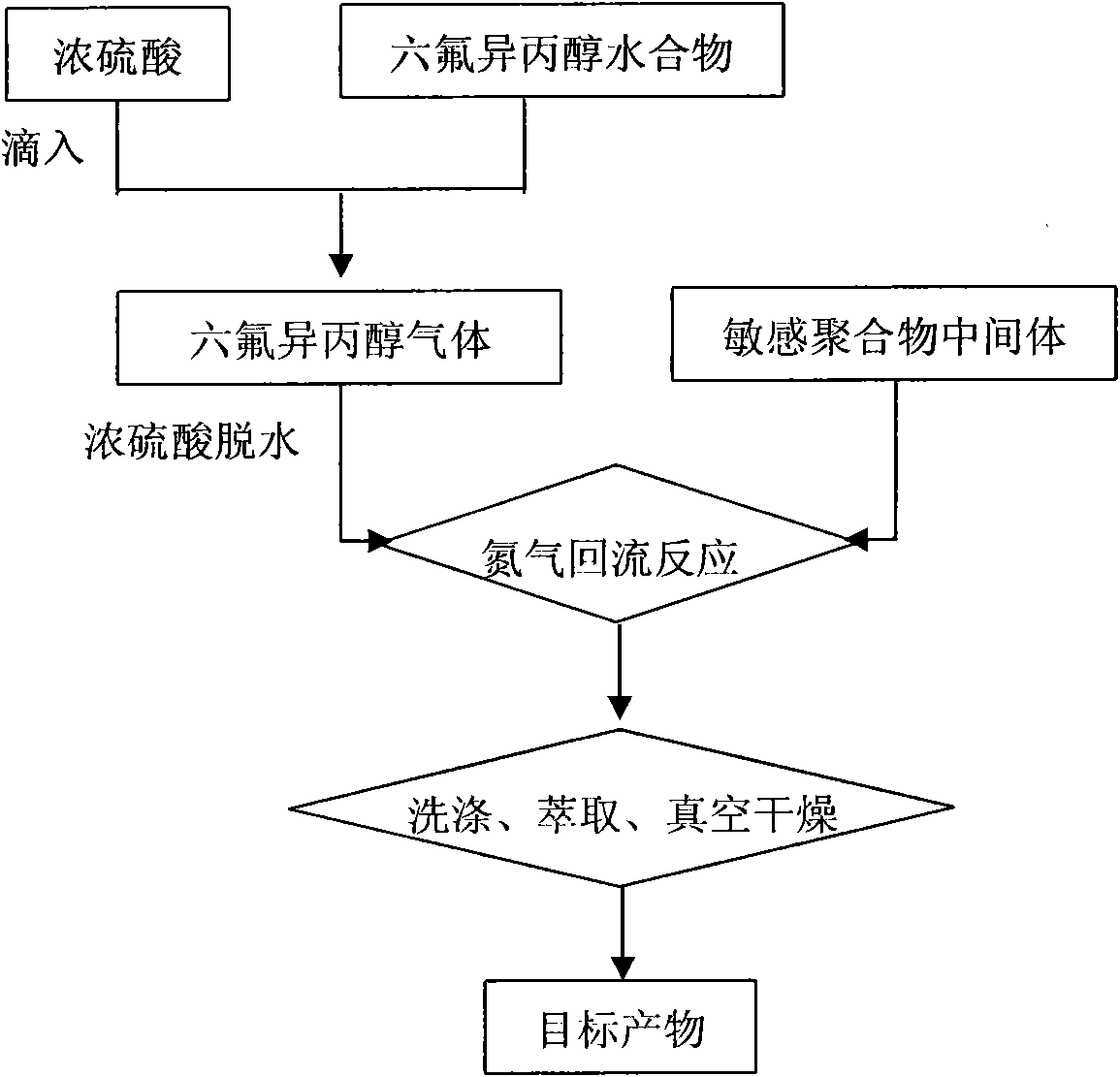

Method used

Image

Examples

specific Embodiment approach 1

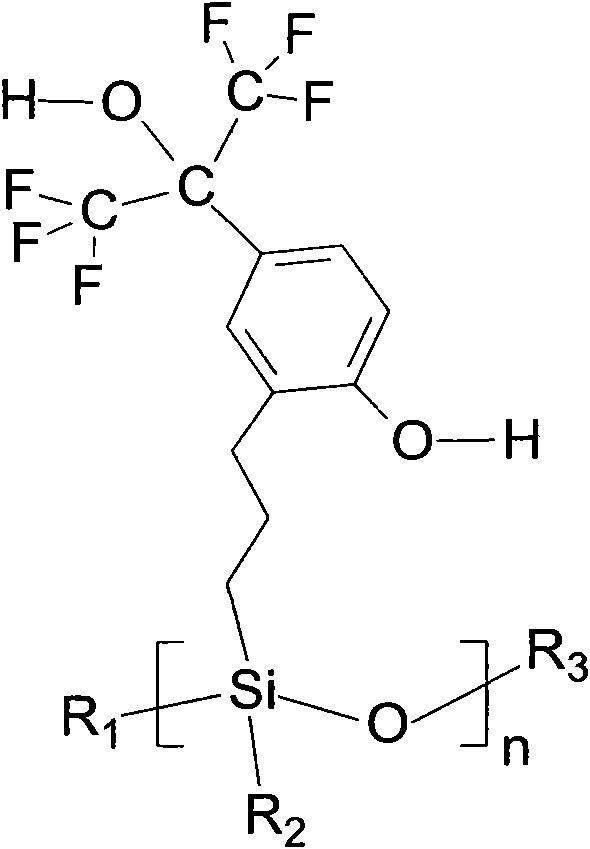

[0032] In this example, what is synthesized is a linear polysiloxane with hexafluoroisopropanol substituent at the end group, its structure is as follows image 3 As shown, the synthesis mechanism can be expressed as:

[0033]

[0034] Among them, n is an integer of 200-500, R 1 and R 3 is trimethylsilane, R 2 For methyl, its preparation method is as follows:

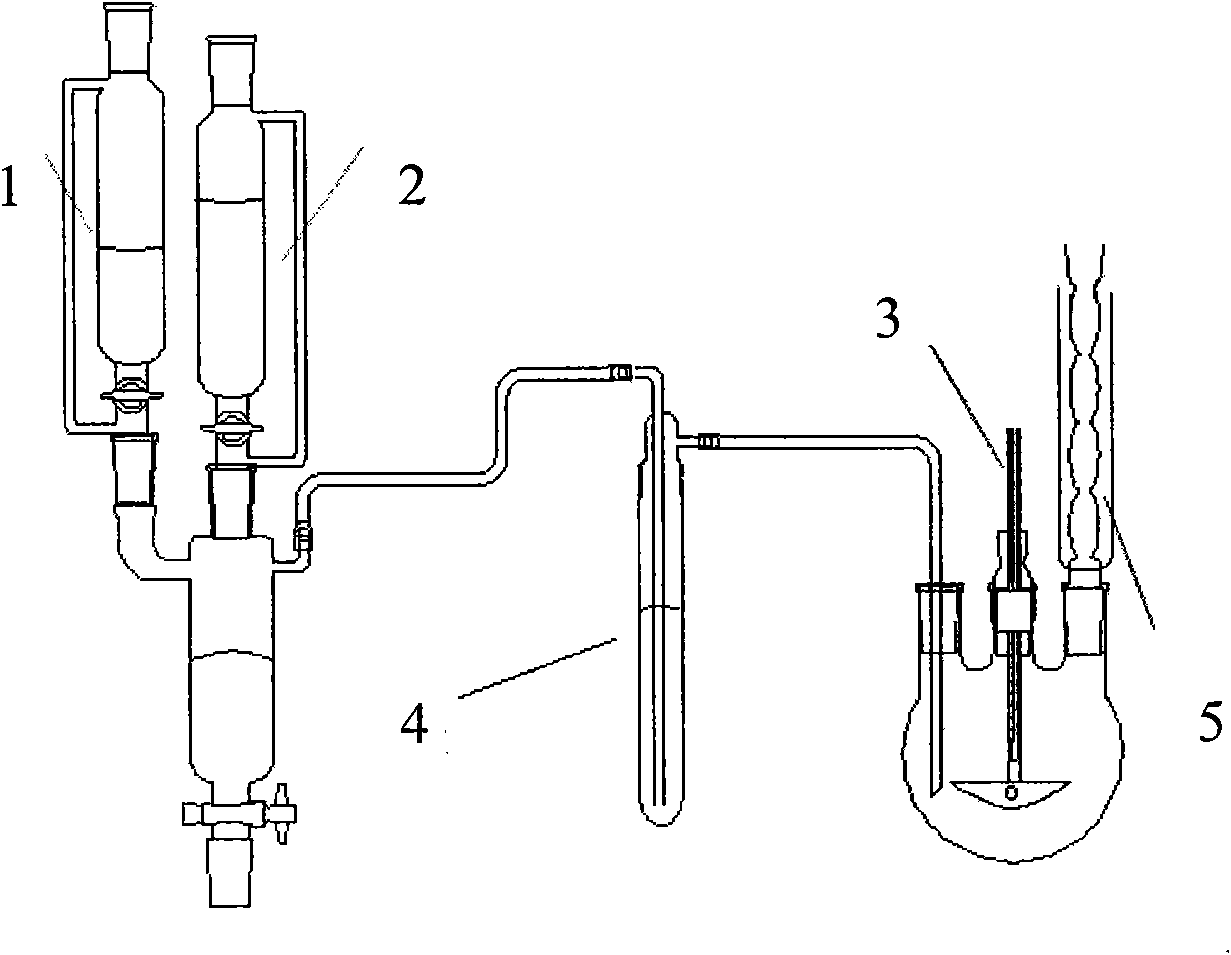

[0035] Under the protection of nitrogen, place 0.01mol of the above-mentioned polysiloxane polymer intermediate in a three-necked bottle equipped with a thermometer and a reflux condenser, and titrate the hexafluoroacetone hydrate produced by concentrated sulfuric acid. After the concentrated sulfuric acid washing solution is treated, it is passed into the reactor for gas-liquid reaction. After the dropwise addition, it is heated to 120°C, stirred and refluxed for 26-28 hours. When the reaction solution turns khaki, stop the reaction and cool To room temperature, purging the reactor repeatedly with nitrogen, so t...

specific Embodiment approach 2

[0036] In this example, what is synthesized is a kind of hyperbranched polycarbosilane whose terminal group contains hexafluoroisopropanol substituent, its structure is as follows Figure 5 As shown, the synthesis mechanism can be expressed as:

[0037]

[0038] The specific preparation method is:

[0039] Under nitrogen protection, place 0.01mol of the above-mentioned three-branched carbosilane hyperbranched polymer intermediate in a three-necked bottle equipped with a thermometer and a reflux condenser, and hexafluoroacetone gas produced by titrating hexafluoroacetone hydrate with concentrated sulfuric acid, After being treated with concentrated sulfuric acid washing solution, it is passed into the reactor for gas-liquid reaction. After the dropwise addition, it is heated to 110°C, stirred and refluxed for 32 hours. When the reaction solution turns light brown, stop the reaction and cool it. To room temperature, purging the reactor repeatedly with nitrogen, so that the hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com