Method for separating ferrum, copper and silicon components from copper smelting residues

A copper smelting slag and separation technology, applied in the field of metallurgical production, can solve the problems of low utility, limited direct application, and difficulty in acting on copper elements, etc., and achieve high comprehensive utilization of resources, high added value of products, and low processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

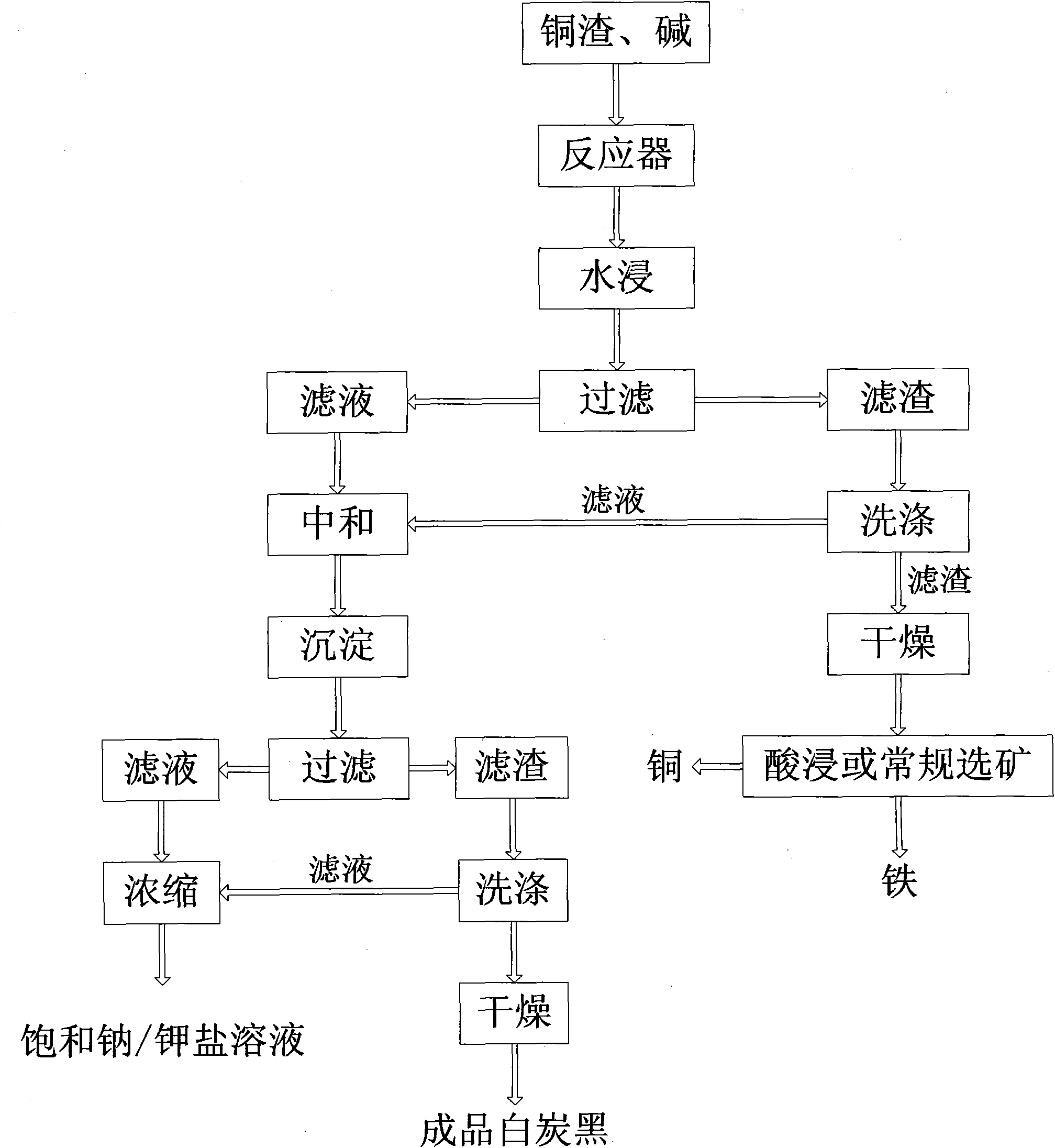

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Grind the copper slag to below 1.0mm, weigh 40g and mix it evenly with sodium hydroxide according to the slag-alkali weight ratio of 1:0.37, place it in a muffle furnace and heat it to 550°C, keep the temperature constant for 3 hours, and wait until the temperature drops to Take it out at about 150°C and place it in hot water (400ml) for water immersion (2 hours), through precipitation and solid-liquid separation. After washing the filter cake twice, use dilute sulfuric acid to carry out acid leaching to extract copper (copper sulfate solution is obtained, the copper recovery rate is 85%); and then filtered, washed, and dried to obtain iron oxide products (iron recovery rate is 92%). Add acid to neutralize the filtrate by water immersion to adjust pH = 4.5. After precipitation and solid-liquid separation, the filter cake is washed twice, and the filter cake is dried to obtain finished white carbon black (silicon recovery rate reaches 92%); the filtrate is conc...

Embodiment 2

[0019] Example 2: Grind copper slag to below 0.6mm and weigh 40g, mix evenly with sodium hydroxide at a slag-to-alkaline weight ratio of 1:2.5, place in a muffle furnace and heat to 350°C, and react at a constant temperature for 2 hours. When it drops to about 150°C, take it out and put it in hot water (400ml) for water immersion (1 hour), through precipitation and solid-liquid separation; after the filter cake is washed twice, use dilute sulfuric acid to carry out acid leaching to extract copper (copper sulfate solution is obtained). , the copper recovery rate is 90%), and then filtered and dried to obtain iron oxide products, and the iron recovery rate is 95%. Add hydrochloric acid to the water leaching filtrate to neutralize and adjust pH = 3, separate the solid and liquid, wash the filter cake twice, and dry the filter cake to obtain the finished white carbon black (silicon recovery rate reaches 96%); the filtrate is concentrated to saturation to obtain chlorinated Sodium ...

Embodiment 3

[0020] Example 3: Weigh 40g of powdered copper slag, mix it evenly with potassium hydroxide at a slag-to-alkaline weight ratio of 1:0.6, place it in a muffle furnace and heat it to 500°C, keep the temperature constant for 3 hours, and wait until the temperature drops to about 200°C Take out and be placed in hot water (400ml) and carry out water immersion (2 hours), through precipitation, solid-liquid separation; After the filter cake is washed twice, acid leaching extracts copper with dilute sulfuric acid (copper sulfate solution is obtained, and the copper recovery rate is 88%), and then filtered and dried to obtain an iron oxide product iron recovery rate of 95%. Add hydrochloric acid to the filtrate to neutralize and adjust the pH value to 6. After solid-liquid separation, the filter cake is washed twice, and the filter cake is dried to obtain finished white carbon black (silicon recovery rate reaches 94%); the filtrate is concentrated to saturation to obtain potassium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com