Large-diameter pillar insulator core and manufacturing method thereof

The technology of a pillar insulator and a manufacturing method, which is applied to the large-diameter pillar insulator core and its manufacturing field, can solve the problems of complex manufacturing process, high rejection rate, difficult transportation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

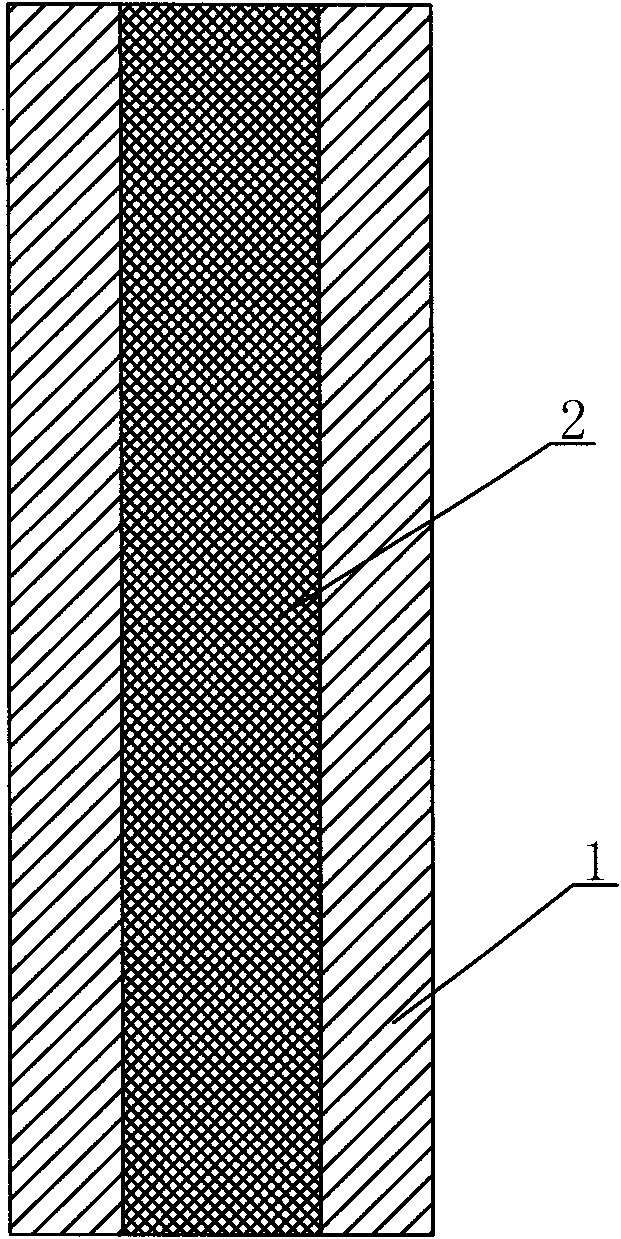

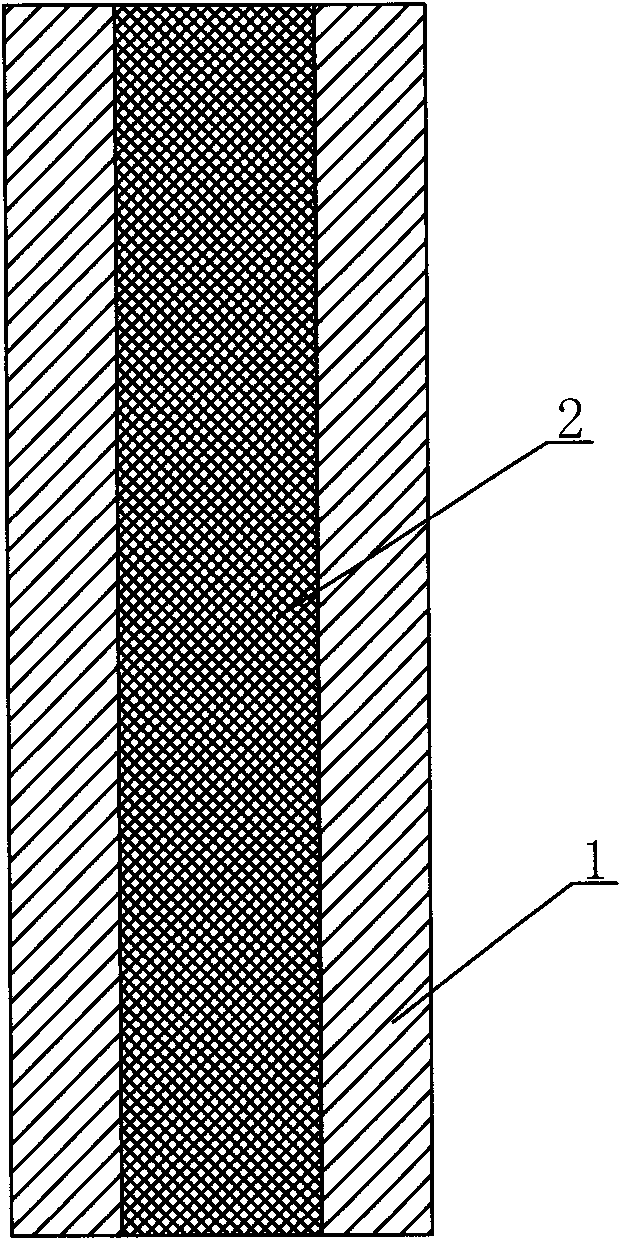

[0024] Such as figure 1 The shown core body of a large-diameter post insulator is composed of an insulating tube 1 and a filling body 2 filled inside the insulating tube 1 and used to assist in reducing leakage current. The diameter of the core of the large-diameter post insulator is 120mm.

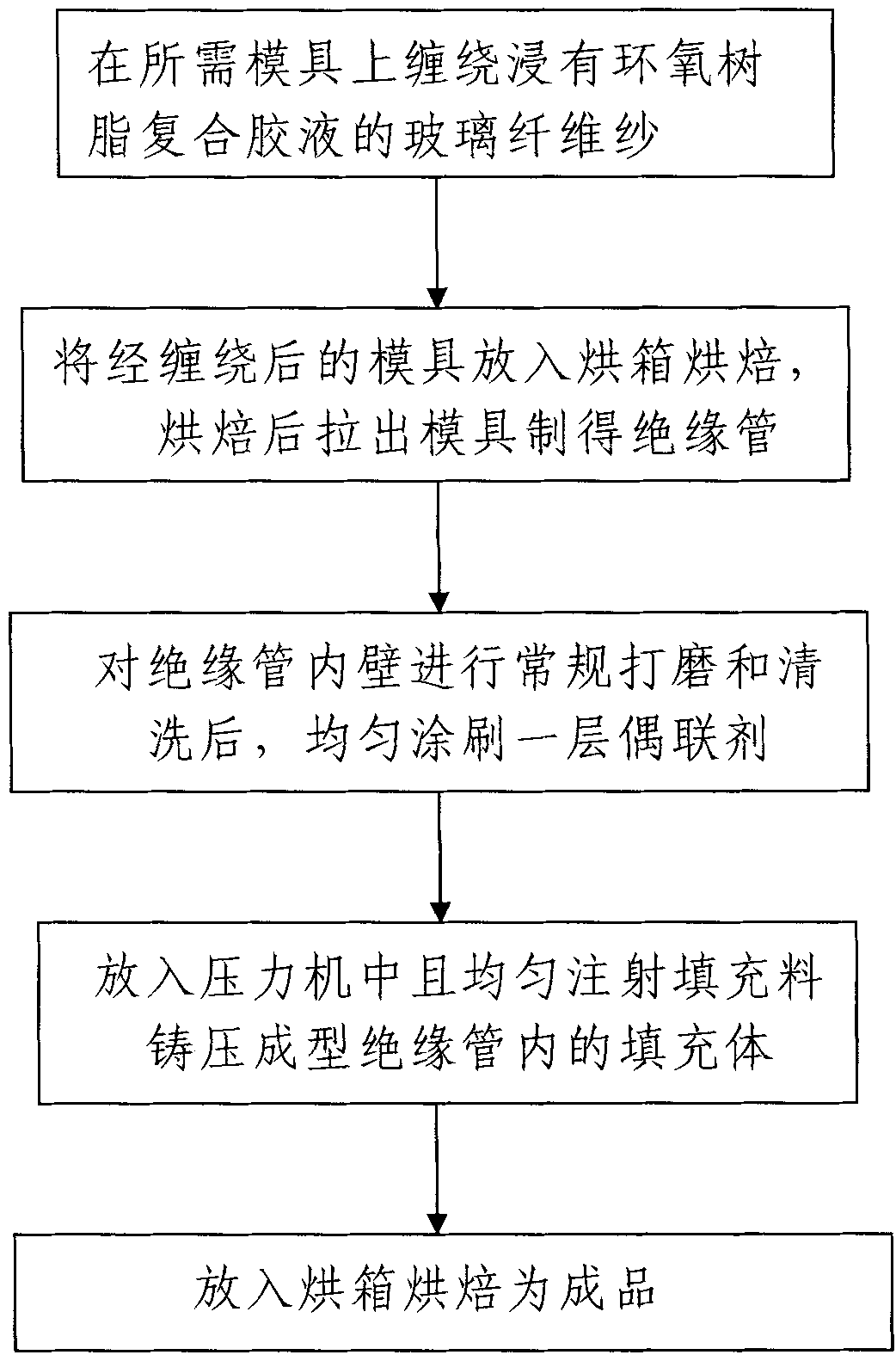

[0025] Such as figure 2 A method for manufacturing the large-diameter post insulator core includes the following steps:

[0026] Step 1, making the insulating tube 1, the manufacturing process includes the following steps:

[0027] Use a winding machine to wind the glass fiber yarn impregnated with the pre-prepared epoxy resin composite glue solution to the mold with the required insulator core length at an angle of 0°~7°, and then put the wound mold into the oven And sequentially bake at 65℃~75℃ once for 2.5h~3.5h, at 125℃~135℃ for 2.5h~3.5h, and at 160℃~170℃ for three times for 2.0h~3.0 h, then naturally cool the coiled tube after three times of baking to room temperature, then tak...

Embodiment 2

[0036] In this embodiment, when making the insulating tube 1, the winding angle of the winding machine is 7°, and the wound molds are baked at 75°C for 3.5 hours for the first time, and at 135°C for 3.5 hours for the second time. h, three times of baking at 170°C for 3.0 hours; the pre-prepared epoxy resin composite glue is prepared by mixing epoxy resin, curing agent and accelerator in a weight ratio of 100:90:2. After the insulating tube 1 is processed, the inner wall of the insulating tube 1 is conventionally polished and cleaned with a cleaning solution, and then evenly coated with a layer of coupling agent. The thickness of the coupling agent is 1.0 mm.

[0037] When processing the filling body 2, the pre-prepared filling material is prepared by mixing chopped yarn, silicon crystal sand and epoxy glue in a ratio of 30:60:20 by weight. The pressure is 15MPa. During the baking process, the casted insulating tube 1 was baked for 3.5 hours at 75°C for the first time, 3.5 hou...

Embodiment 3

[0041] In this embodiment, when making the insulating tube 1, the winding angle of the winding machine is 3.5°, and the wound mold is baked at 70° C. for 3 hours, and then baked at 130° C. for 3 hours. Bake three times at 165°C for 2.5 hours; the pre-prepared epoxy resin composite glue is prepared by mixing epoxy resin, curing agent and accelerator in a weight ratio of 100:80:1.5. After the processing of the insulating tube 1 is completed, the inner wall of the insulating tube 1 is conventionally polished and cleaned with a cleaning solution, and then evenly coated with a layer of coupling agent, the thickness of which is 0.8 mm.

[0042]When processing the filling body 2, the pre-prepared filling material is prepared by mixing chopped yarn, silicon crystal sand and epoxy glue in a ratio of 28:55:18 by weight. The pressure is 12MPa. During the baking process, the casted insulating tube 1 was baked at 70° C. for 3 hours for a first time, 130° C. for 3 hours, and 165° C. for 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com