Bicolor phosphorescent thermopaint

A temperature-measuring coating and phosphorescence technology, applied in the direction of luminous coating, polyester coating, epoxy resin coating, etc., to achieve the effect of low light conditions, simple preparation method and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

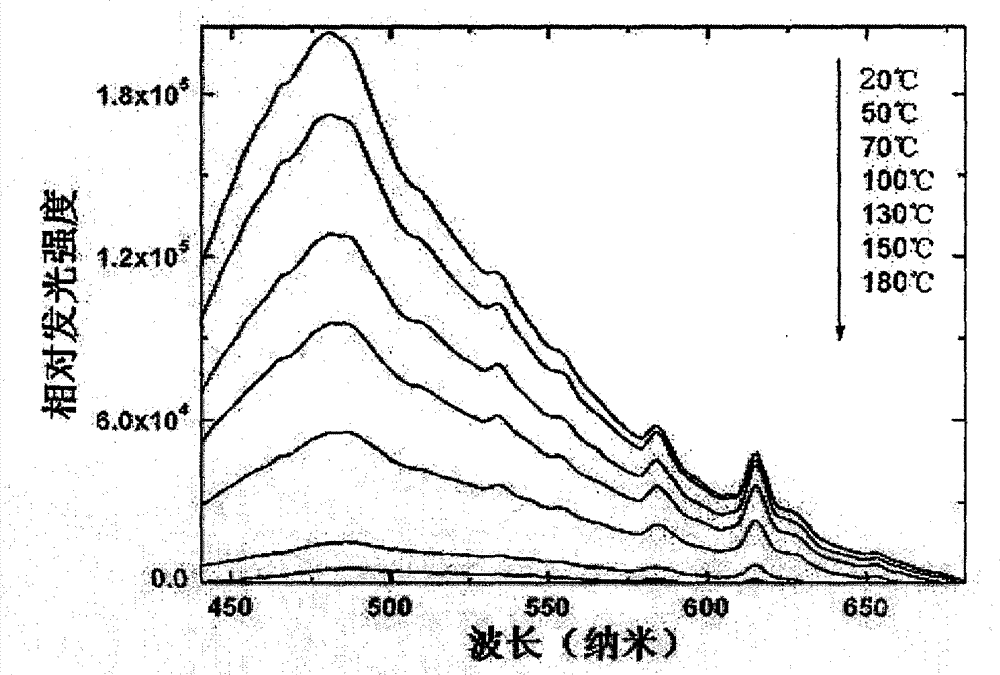

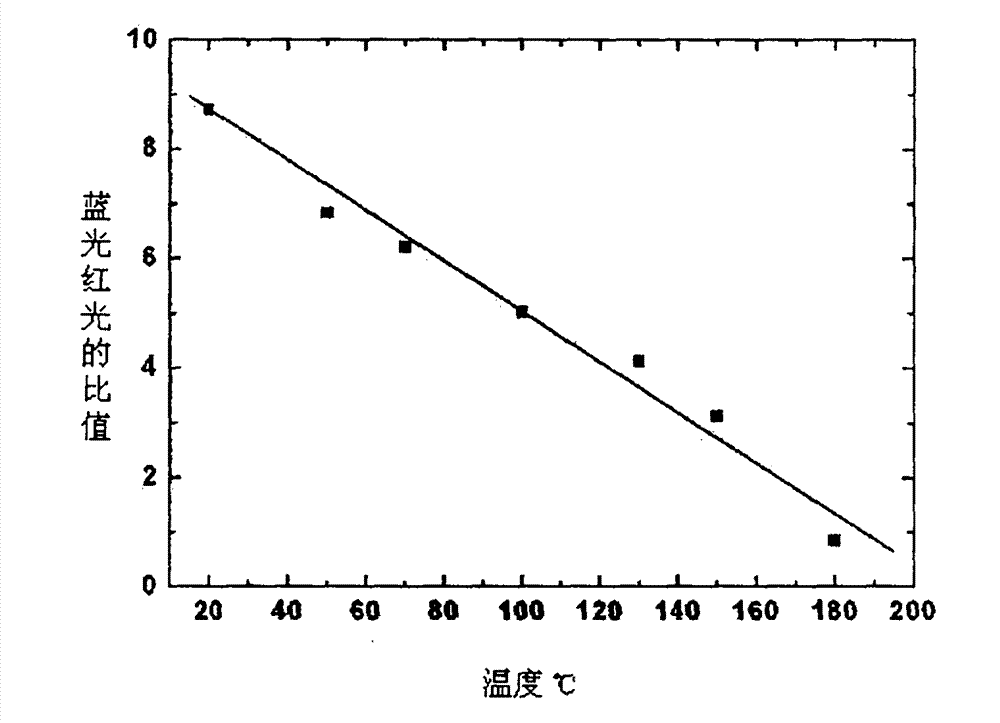

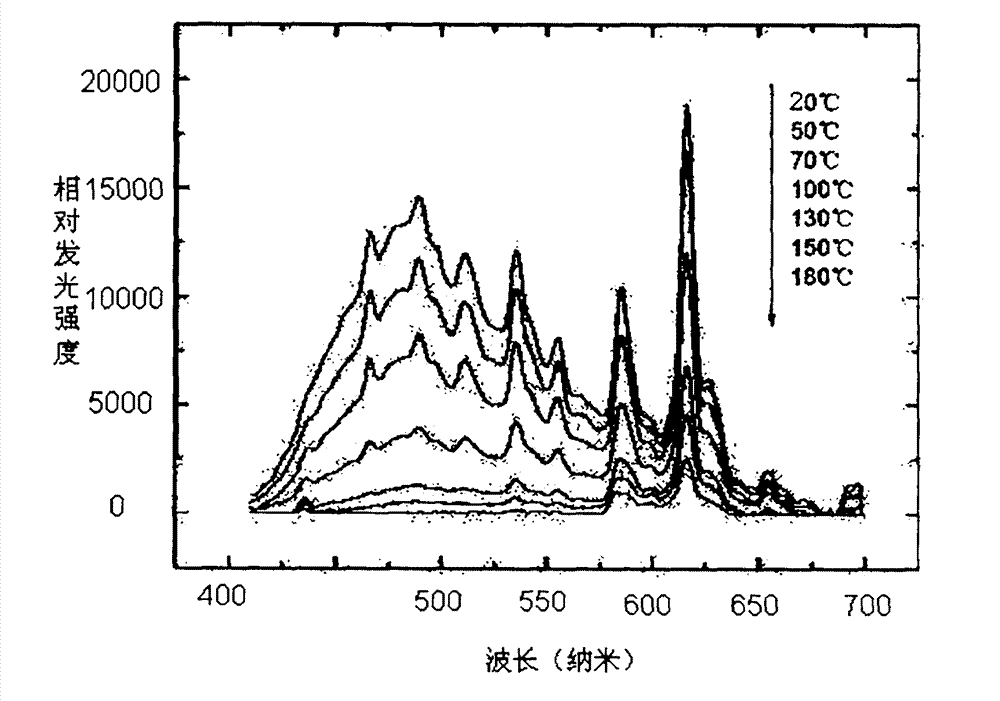

Method used

Image

Examples

specific Embodiment

[0040] Specific examples are shown in the following table:

[0041]

[0042]

[0043] Only take Example 5 as an example to briefly describe the preparation process of the present invention, and the principles of the preparation process of other embodiments are the same.

[0044] 1. Weigh strontium carbonate, cerium oxide and europium oxide at an atomic ratio of 0.0004, mix them uniformly, and react at 1000°C for 10 hours to obtain Sr 1.9996 CeO 4 :0.0004Eu 3+ Luminescent material in blocks.

[0045] 2. The luminescent material Sr 1.9996 CeO 4 :0.0004Eu 3+ The block material is coarsely crushed by a jaw crusher, then ground into a fine powder by a ball mill, and passed through a 250-mesh sieve.

[0046] 3. Sieved Sr 1.9996 CeO 4 :0.0004Eu 3+ After the powder is washed with water and absolute ethanol, it is dried at 200 degrees Celsius.

[0047] 4. The dried Sr 1.9996 CeO 4 :0.0004Eu 3+ The powder is 40% by mass of the luminescent material, added to the matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com