Alternating current frequency conversion high-speed asynchronous motor

An asynchronous motor and AC frequency conversion technology, which is applied in the direction of asynchronous induction motors, manufacturing motor generators, electric components, etc., can solve the problems of increased motor loss, large moment of inertia, high motor speed, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

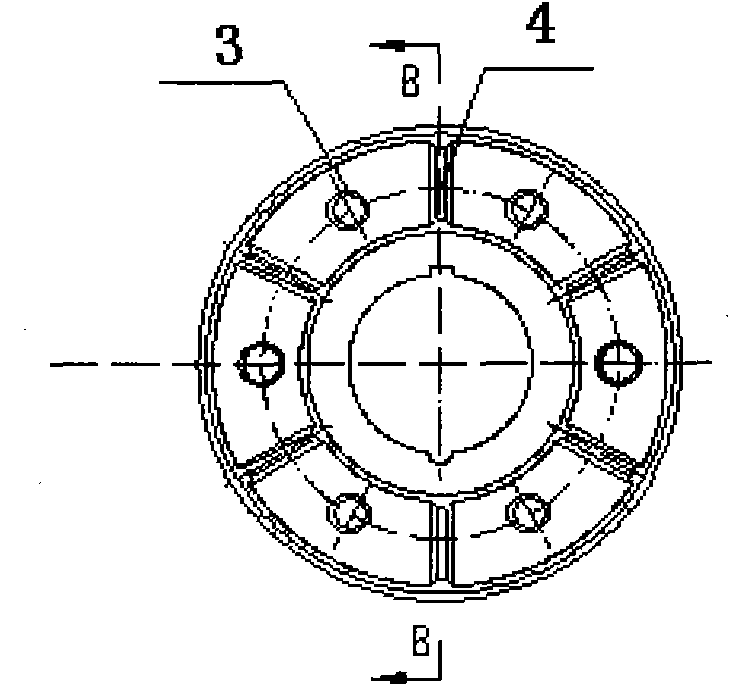

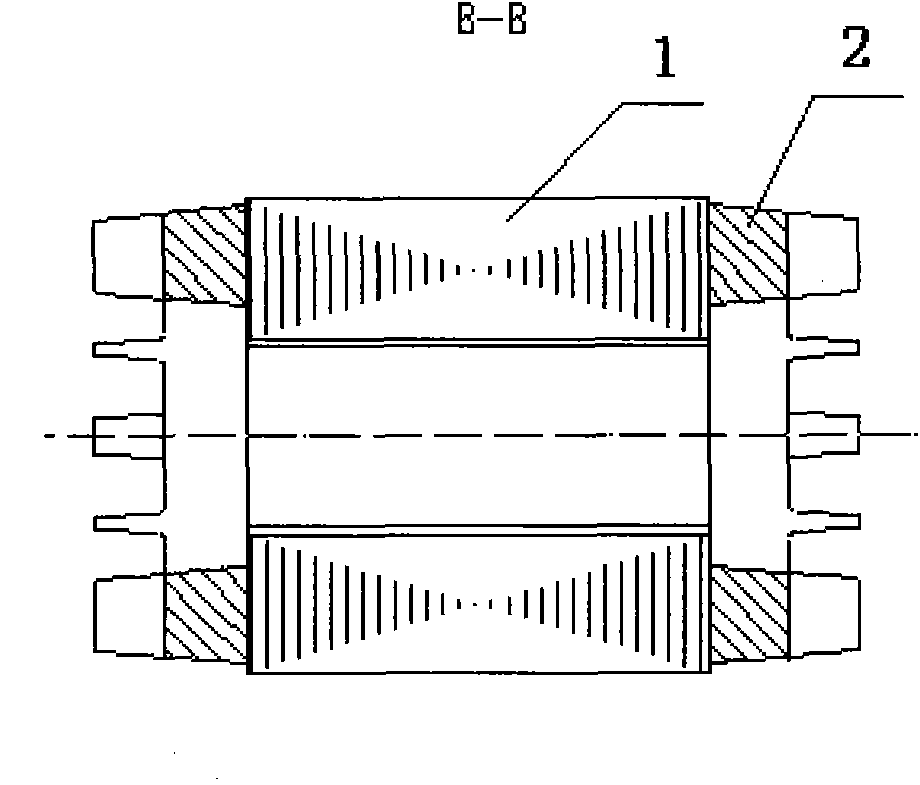

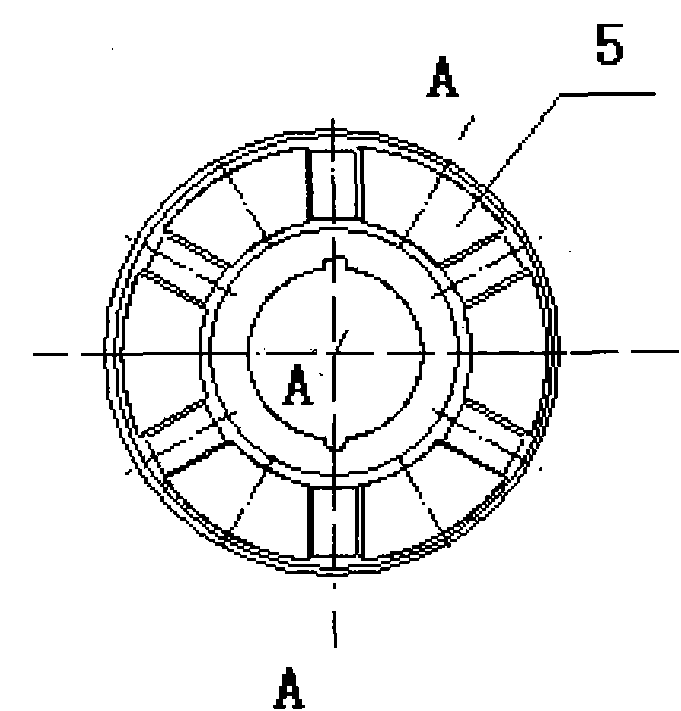

[0031] The AC variable-frequency high-speed asynchronous motor has a rotor, a stator, and a frequency converter. The frequency converter is used to control the speed of the motor. The rated frequency of the frequency converter is set to 200Hz. The stator inner diameter Di 1 The effective length Leff of the iron core ranges from 0.4 to 0.8; the punching material of the stator and rotor of the motor is made of cold-rolled silicon steel plate with good magnetic conductivity; the flux density of the motor is controlled within a certain range: the flux density of the stator teeth is 0.9 to 1.4 T; stator yoke magnetic density 0.8 ~ 1.1T; rotor tooth magnetic density 0.9 ~ 1.35T; rotor yoke magnetic density 0.6 ~ 0.85T; air gap magnetic density 0.45 ~ 0.6T; stator winding electric density 3.0 ~ 5.0A / mm 2 , Rotor bar electric density 1.1~3.0A / mm 2 , The line load is 180-250A / cm; the insulation uses H-level insulation, and the first turn is covered with an insulating tube; the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com