Soft capsule of lycopene

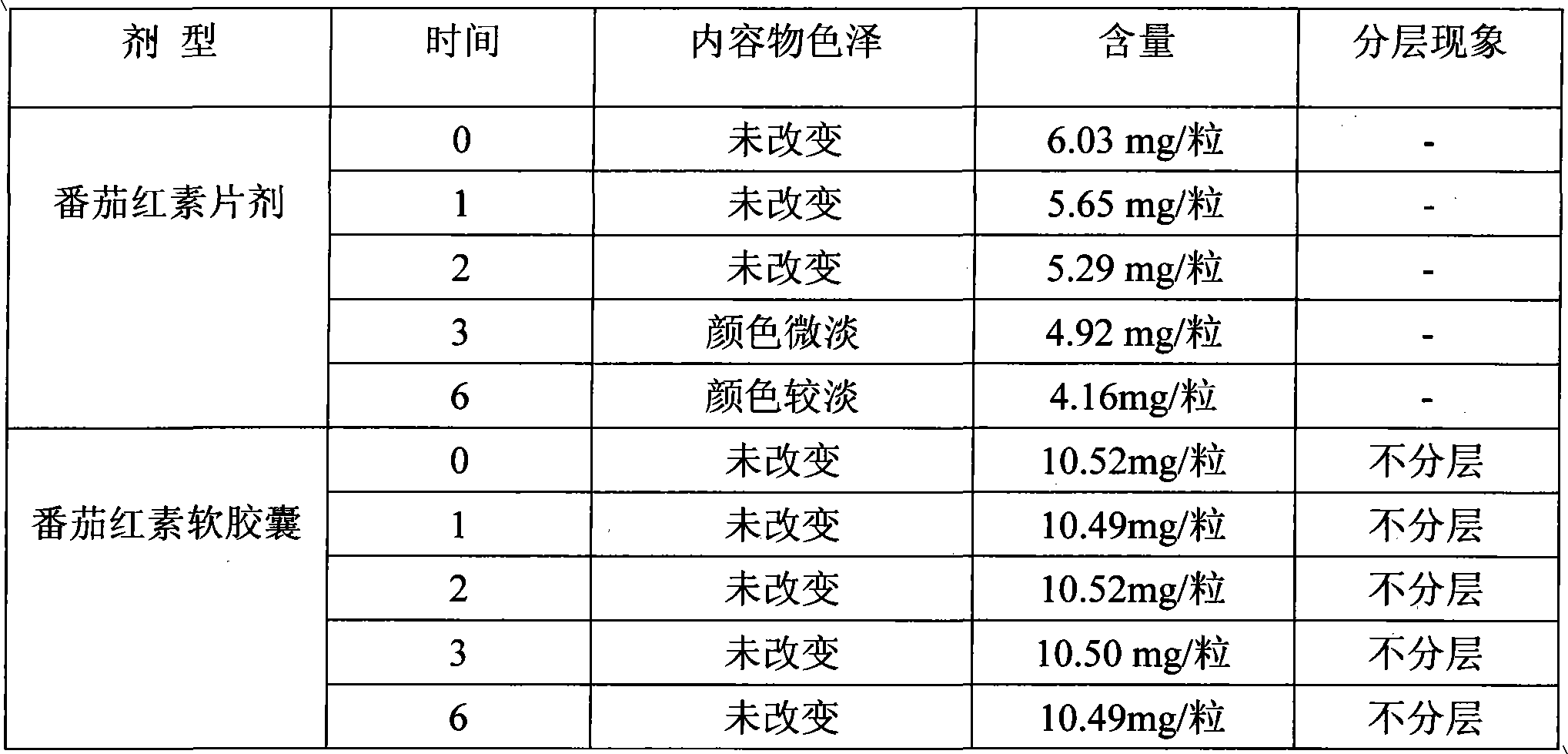

A lycopene and soft capsule technology, applied in the application, food preparation, food science and other directions, can solve the problems of unstable product performance, easy oxidation of lycopene, easy stratification of contents, etc. Convenience, less loss of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A lycopene soft capsule, which is composed of contents and capsule materials. The preparation of the contents is as follows: take 31kg of soybean oil and heat it to 60°C, add 4kg of beeswax, stir to dissolve it, add 60kg of lycopene oleoresin refined by supercritical extraction and 5kg of natural vitamin E, stirred evenly, and prepared into a uniform and stable content by a high-pressure homogenizer;

[0015] Glue: according to the following percentage by weight: get 46% gelatin: 40% water: 14% glycerin to carry out glue;

[0016] According to the conventional method, the lycopene soft capsule is made through the processes of pressing pills, shaping and drying, washing pills, drying pills, picking pills, internal packaging and external packaging.

Embodiment 2

[0018] A lycopene soft capsule, which consists of contents and capsule materials. The contents are made by taking 75kg of soybean oil and heating it to 80°C, adding 6kg of beeswax, stirring to dissolve it, adding 14kg of lycopene crystals and 5kg of natural vitamin E, Stir evenly, and prepare homogeneous and stable content through colloid mill and high-pressure homogenizer in turn;

[0019] Glue: according to the following percentage by weight: get 46% gelatin: 40% water: 14% glycerin to carry out glue;

[0020] According to the conventional method, the lycopene soft capsule is made through the processes of pressing pills, shaping and drying, washing pills, drying pills, picking pills, internal packaging and external packaging.

Embodiment 3

[0022] A lycopene soft capsule, which is composed of contents and capsule materials. The preparation of the contents is as follows: take 78kg of corn oil and heat it to 50°C, add 5kg of beeswax, stir to dissolve it, add 15kg of lycopene crystals, 1kg of natural vitamin E and Vitamin C 1kg, stir evenly, and prepare uniform and stable content through colloid mill;

[0023] Glue: according to the following weight percentage: get 50% gelatin: 30% water: 20% glycerin to carry out glue;

[0024] According to the conventional method, the lycopene soft capsule is made through the processes of pressing pills, shaping and drying, washing pills, drying pills, picking pills, internal packaging and external packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com