Glyphosate triammonium and preparation method and application thereof

A technology of glyphosate and glyphosate acid, applied in the field of glyphosate triammonium, can solve problems such as end-user acceptability limitations, and achieve the effects of broadening the scope of use, reducing costs, and reducing the amount of free ammonium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

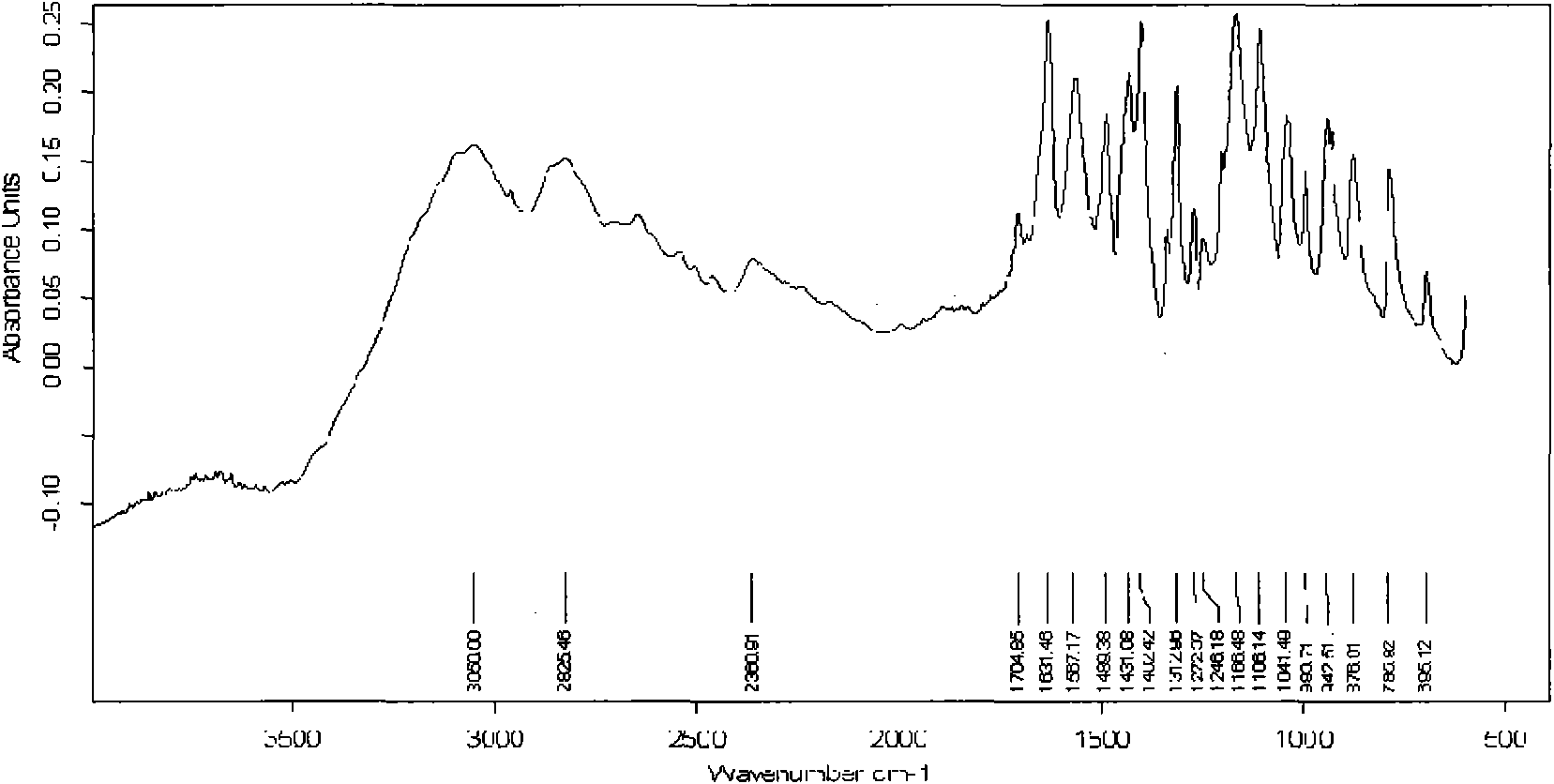

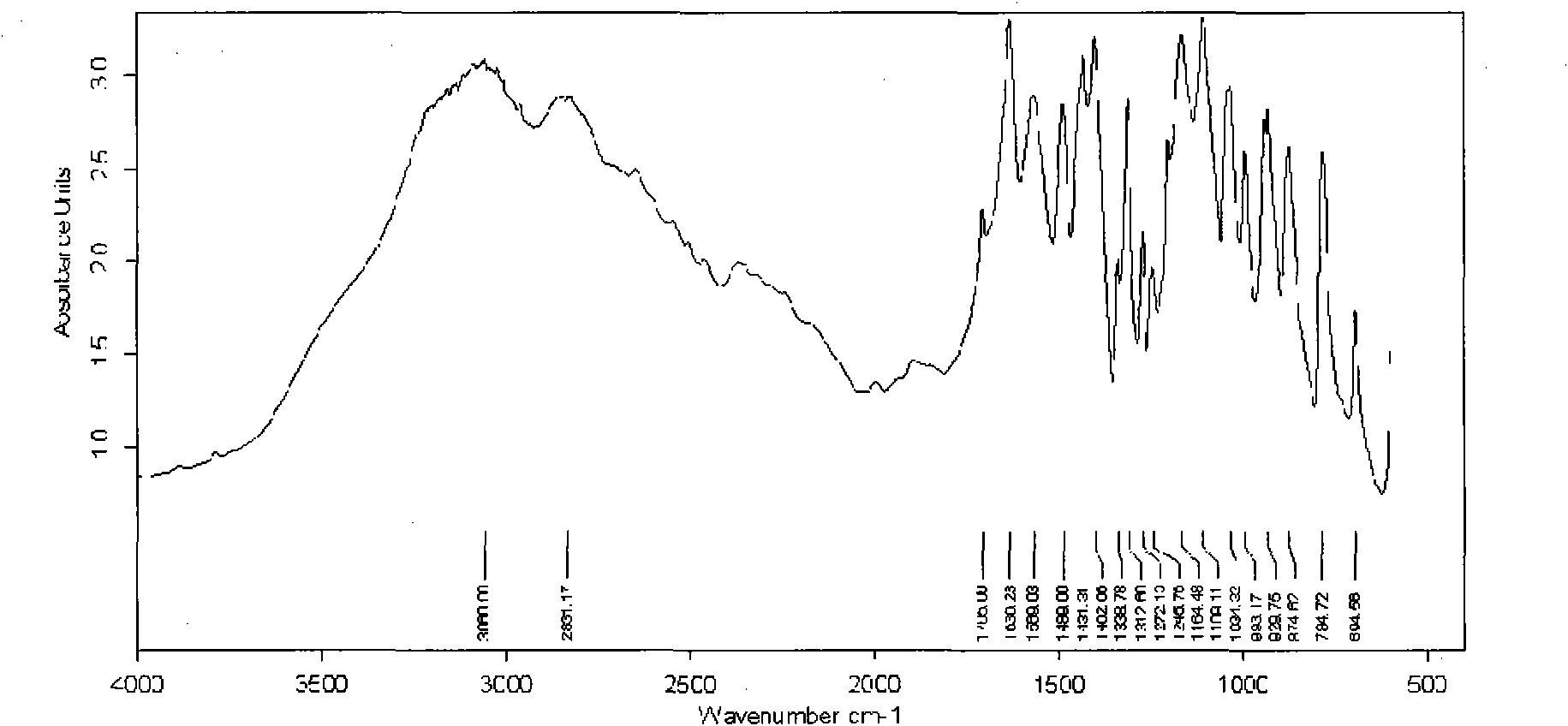

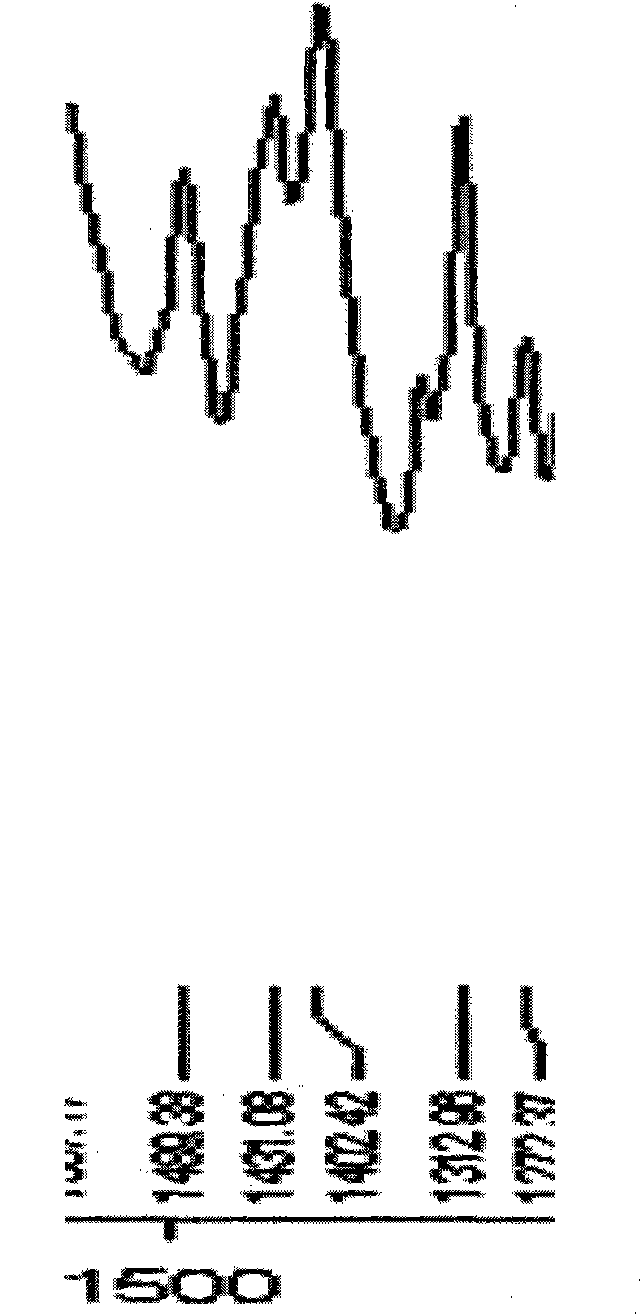

Image

Examples

Embodiment 1

[0039] Embodiment 1 prepares triammonium glyphosate

[0040] A kind of making of triammonium glyphosate is obtained through the following process: a, add water in the reactor with stirring and cooling device, add glyphosate acid in the reactor under stirring, make glyphosate Phosphonic acid is uniformly dispersed to form a suspension; wherein, the glyphosate acid addition is 23% (wt) of the whole suspension; b, slowly feed ammonia into the reactor, the mol ratio of glyphosate acid to ammonia The ratio is 1:2.5; since a large amount of heat will be generated during the reaction, the reactor is cooled to ensure that the temperature is stirred at 95°C. When passing ammonia gas until the reaction solution is transparent, continue to pass ammonia until the weight gain of the entire reaction system is equal to the measured amount of ammonia gas. At the same time, check the pH value of the reaction solution. The pH value is 7.3. Finish.

Embodiment 2

[0041] Embodiment 2 prepares triammonium glyphosate

[0042] A kind of making of triammonium glyphosate is obtained through the following process: a, add water in the reactor with stirring and cooling device, add glyphosate acid in the reactor under stirring, make glyphosate Phosphonic acid is uniformly dispersed to form a suspension; wherein, the glyphosate acid addition is 55% (wt) of the entire suspension; b, slowly add concentrated ammonia in the reactor, and the mol ratio of glyphosate acid to ammonia is 1 : 2.6; Since a large amount of heat will be generated during the reaction, the reactor is cooled to ensure that the temperature is stirred at 25°C. When concentrated ammonia water is added until the reaction liquid is transparent, continue to add concentrated ammonia water until the weight gain of the entire reaction system is equal to the measured concentrated ammonia water amount; at the same time, detect the pH value of the reaction liquid, and the pH value is 8, and...

Embodiment 3

[0043] Embodiment 3 prepares triammonium glyphosate

[0044] A kind of making of triammonium glyphosate is obtained through the following process: a, add water in the reactor with stirring and cooling device, add glyphosate acid in the reactor under stirring, make glyphosate Phosphonic acid is uniformly dispersed to form a suspension; wherein, the glyphosate acid addition is 39% (wt) of the entire suspension; b, slowly adding liquid ammonia to the reactor, the mol ratio of glyphosate acid to ammonia is 1 : 2.9; Since a large amount of heat will be generated during the reaction, the reactor is cooled to ensure that the temperature is stirred at 40°C. When liquid ammonia is added until the reaction liquid is transparent, continue to add liquid ammonia until the weight gain of the entire reaction system reaches the measured amount of liquid ammonia. The pH value of the reaction liquid is detected to be 9.3, and the stirring is continued until the reaction is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com