Additive composition for improving methane production rate, and application thereof

A technology of gas production rate and composition, applied in the direction of waste fuel, fermentation, etc., can solve the problems of slow gas production, carbon-nitrogen ratio imbalance, and low gas production, so as to be easy to popularize and apply, enhance the activity of anaerobic bacteria, The effect of increasing pool capacity utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 2.0 kg of pre-stacked potato skins and 2.0 L of fermented strains were evenly mixed and loaded into a biogas reactor, and an appropriate amount of water was added to prepare a fermented liquid with a solid concentration of 4%.

[0023] In the first group, 0 g / L of the additive composition was added to the fermentation broth, that is, no additive composition was added.

[0024] The second group, add the additive composition 1 to the fermentation broth, and add the raw materials in the additive composition 1 to the biogas slurry in the following proportions: urea: 0.5g / L; K 2 HPO 4 ·3H 2 O: 0.25g / L; KH 2 PO 4 : 0.15g / L; MgSO 4 ·7H 2 O: 0.05g / L; vitamin B 1 : 0.003g / L; Vitamin B 2 : 0.003g / L and vitamin B 3 : 0.003g / L.

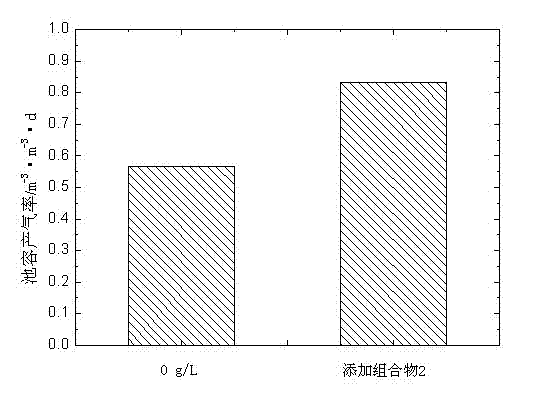

[0025] Control the temperature of the biogas slurry within 27±3°C, and monitor the changes in parameters such as the tank volume gas production rate and methane concentration during the 30-day fermentation process, such as figure 1 and figure 2...

Embodiment 2

[0027] 2.0 kg of pre-stacked potato skins and 2.0 L of fermented strains were evenly mixed and loaded into a biogas reactor, and an appropriate amount of water was added to prepare a fermented liquid with a solid concentration of 4%.

[0028]In the first group, 0 g / L of the additive composition was added to the fermentation broth, that is, no additive composition was added.

[0029] The second group, add the additional composition 2 to the fermentation broth, and add the raw materials in the additional composition 2 to the biogas slurry in the following proportions: urea: 1.00g / L; K 2 HPO 4 ·3H 2 O: 0.75g / L; KH 2 PO 4 : 0.43g / L; MgSO 4 ·7H 2 O: 0.10g / L; vitamin B 1 : 0.005g / L; Vitamin B 2 : 0.005g / L and vitamin B 3 : 0.005g / L.

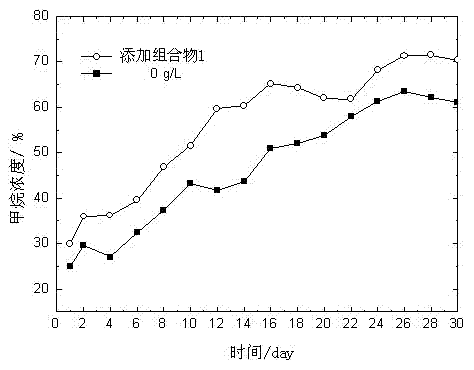

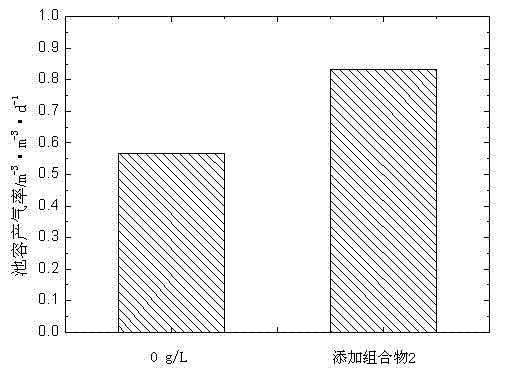

[0030] Control the temperature of the biogas slurry within 27±3°C, and monitor the changes in parameters such as the tank volume gas production rate and methane concentration during the 30-day fermentation process, such as image 3 and Figu...

Embodiment 3

[0032] 2.0 kg of pre-stacked potato skins and 2.0 L of fermented strains were evenly mixed and loaded into a biogas reactor, and an appropriate amount of water was added to prepare a fermented liquid with a solid concentration of 4%.

[0033] In the first group, 0 g / L of the additive composition was added to the fermentation broth, that is, no additive composition was added.

[0034] In the second group, the additive composition 3 is added to the fermentation broth, and the raw materials in the additive composition 3 are added to the biogas slurry in the following proportions: urea: 1.5g / L; K 2 HPO 4 ·3H 2 O: 1.0g / L; KH 2 PO 4 : 0.55g / L; MgSO 4 ·7H 2 O: 0.3g / L; vitamin B 1 : 0.007g / L; Vitamin B 2 : 0.007g / L and vitamin B 3 : 0.007g / L.

[0035] Control the temperature of the biogas slurry within 27±3°C, and monitor the changes in parameters such as the tank volume gas production rate and methane concentration during the 30-day fermentation process, such as Figure 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com