Electrolysis system for preparing hypochlorous acid water

An electrolysis system and hypochlorous acid technology, applied in the field of electrolysis systems, can solve problems such as increasing the impedance of the electrolytic sheet, reducing the current flow, and hypochlorous acid water that does not meet the pH value, so as to avoid poor circulation, stabilize discharge, and produce high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

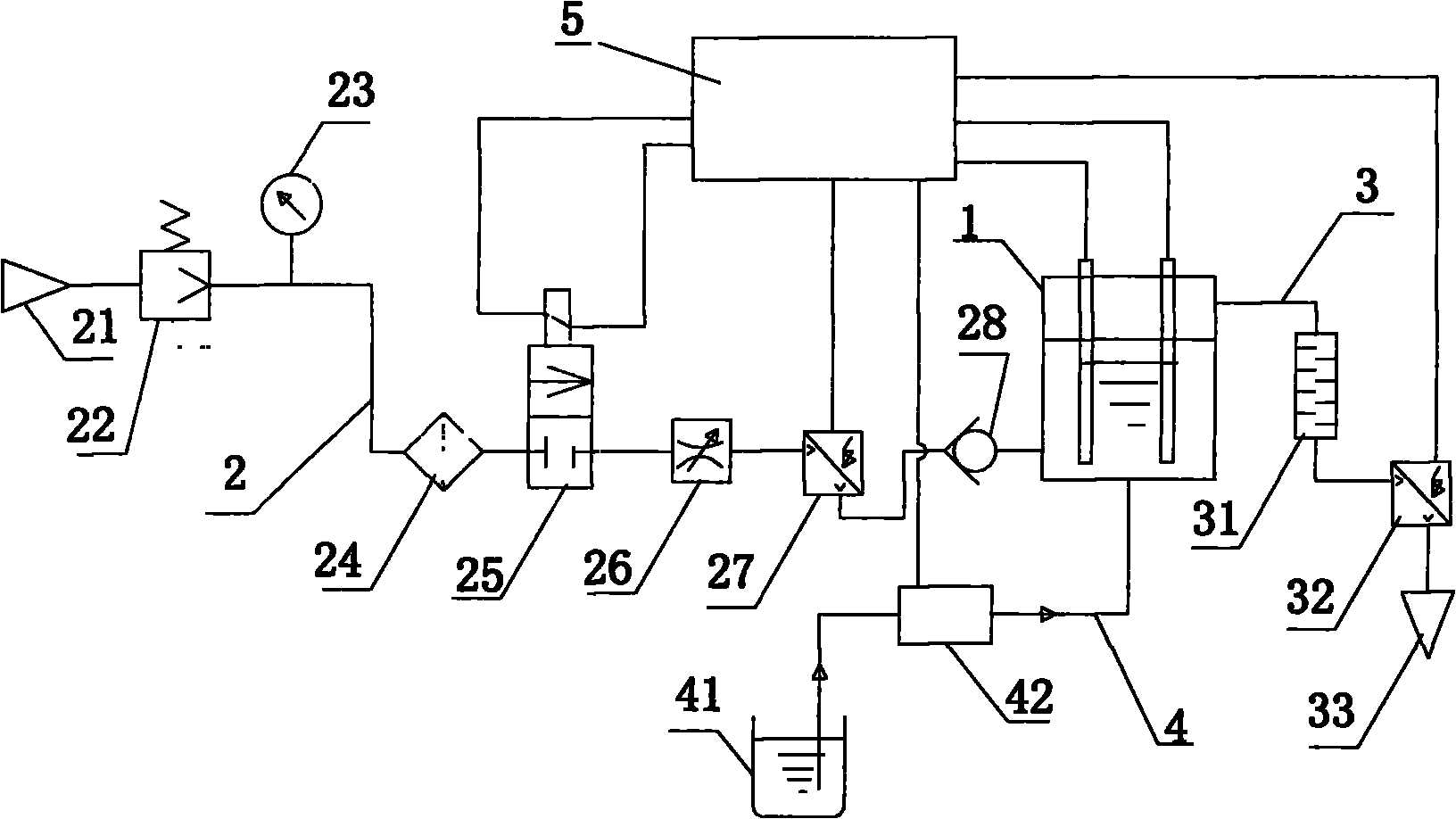

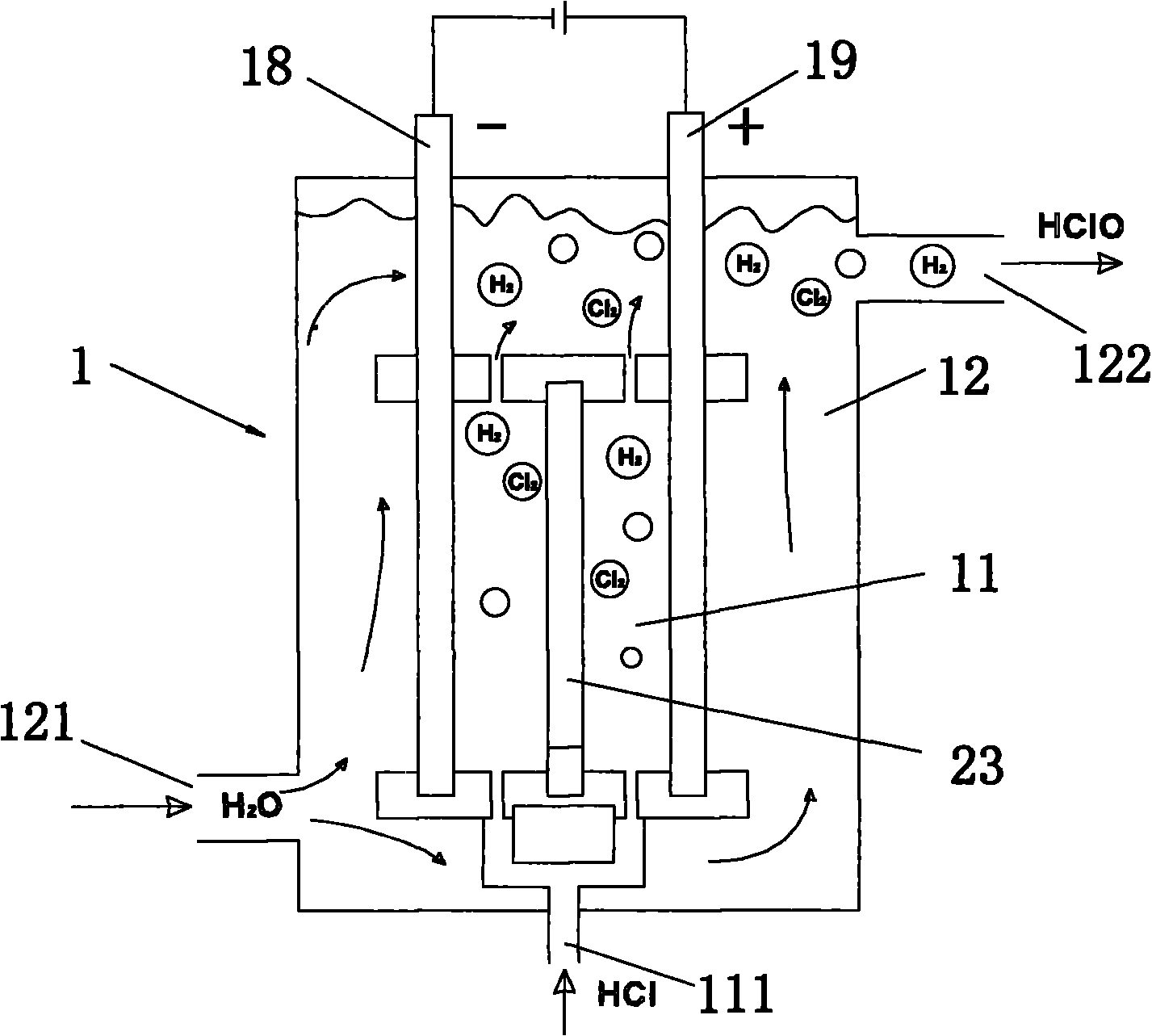

[0028] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an electrolysis system for preparing hypochlorous acid water in a preferred embodiment of the present invention, figure 2 yes figure 1 Schematic diagram of the electrolytic cell in the middle; the electrolytic system for preparing hypochlorous acid water of the present invention includes: electrolytic cell 1, tap water supply pipeline 2, hypochlorous acid water discharge pipeline 3, hydrochloric acid supply pipeline 4 and intelligent control device 5.

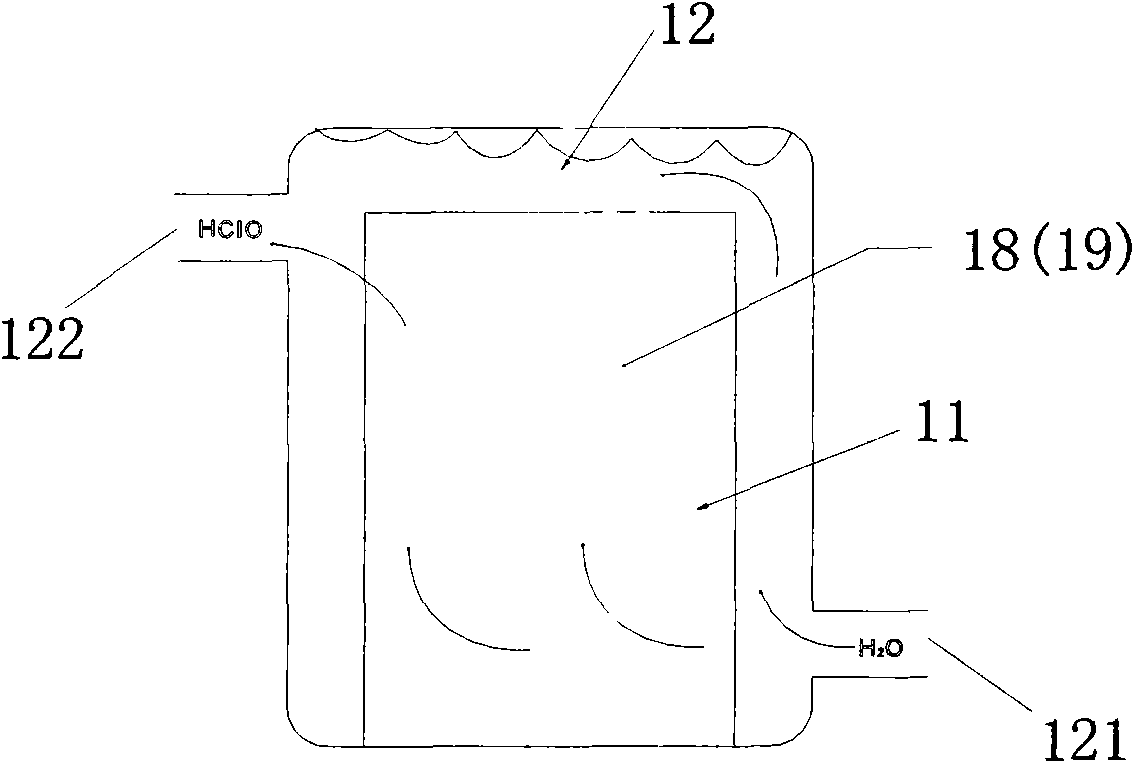

[0029] refer to figure 2 , figure 2 Shown is figure 1 Schematic diagram of the structure of the electrolytic cell; the electrolytic cell 1 is separated and formed with an inner tank 11 for containing hydrochloric acid electrolyte and an outer tank 12 for circulating tap water, and the inner tank 11 is provided with cathode and anode electrolytic sheets 18 , 19, the lower end of which is provided with an electrolyte inflow hole 111 for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com